Compound and high polymer material applying same

A technology of polymer materials and compounds, which is applied in the fields of compounds of Group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods, etc., and can solve problems such as high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

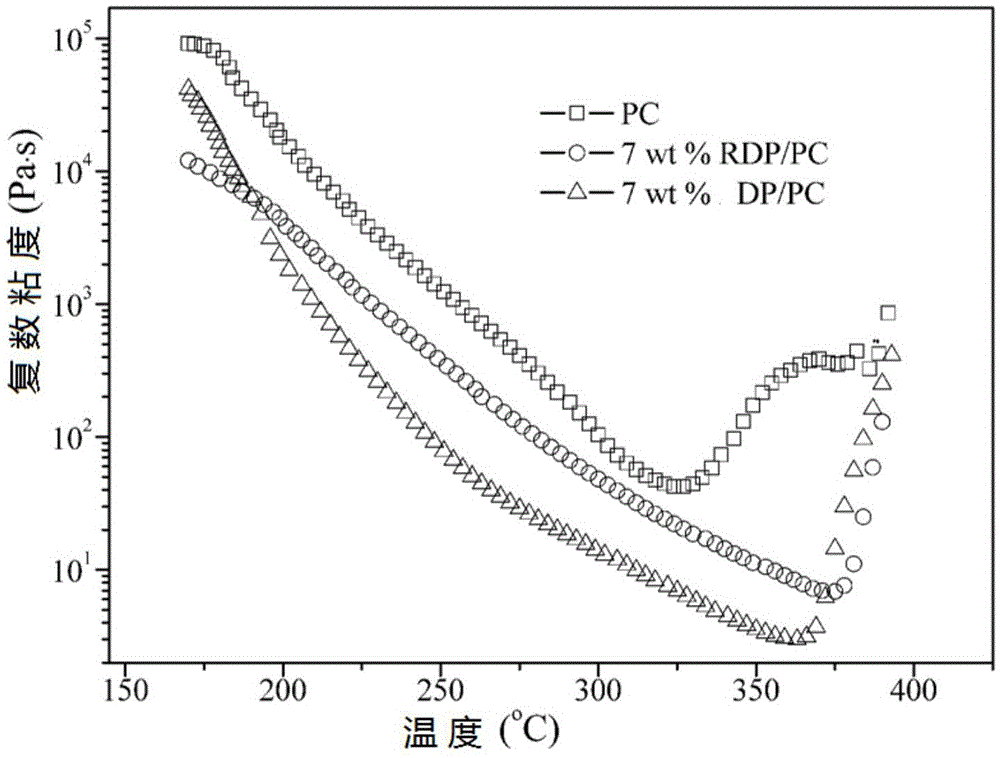

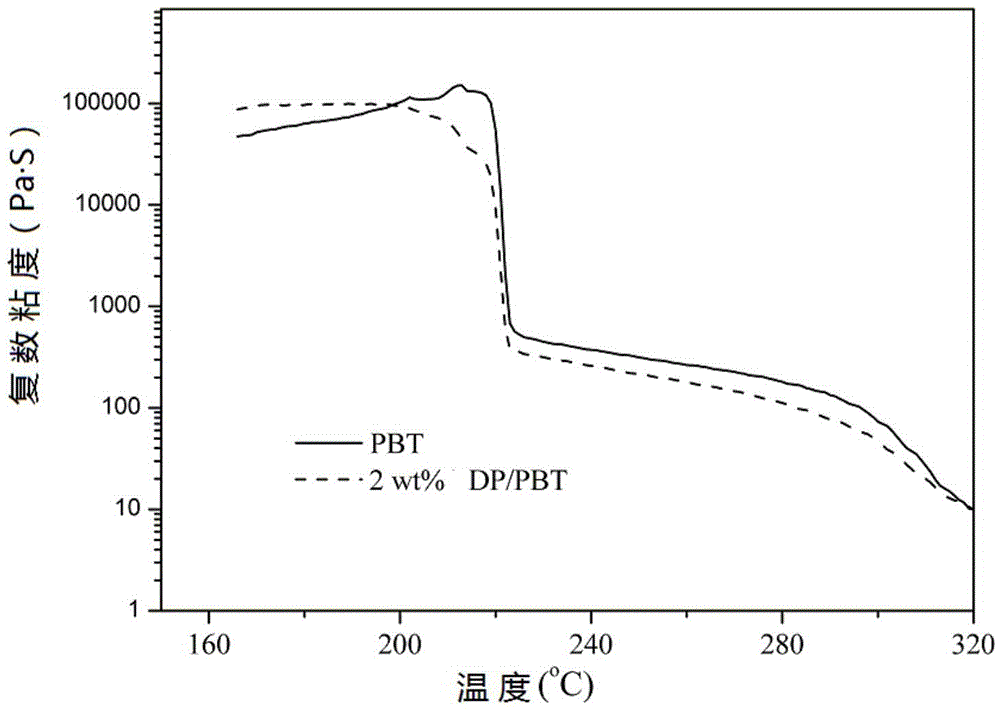

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of 3,3-bis(4-hydroxyphenyl)benzalkrolactam :

[0074] The chemical structural formula of 3,3-bis(4-hydroxyphenyl)benzalkolactam is formula VII-OH.

[0075] Add 63.6g of phenolphthalein and 550g of ammonia water into a three-necked flask with a condenser and a stirrer. The color of the solution is dark purple. Stir at room temperature for 7 days until the color of the solution turns pink, and pour it into 1000ml of 3.7% dilute In the hydrochloric acid solution, a large amount of solids were precipitated, and the pH was adjusted to about 7 again, filtered, washed with water, and vacuum-dried at 80° C. to constant weight to obtain 60.23 g of pink powdery solids with a yield of 95%. pass 1 HNMR analysis gave 3,3-bis(4-hydroxyphenyl)benzalkrolactam.

[0076] Preparation of 3,3-bis(4-hydroxyphenyl)benzalactam bis(phenoxyphosphate)

[0077] Add 80ml of deionized water, 4g (0.1mol) of sodium hydroxide and 15.9g of 3,3-bis(4-hydroxyphenyl) benzalkolactam into ...

Embodiment 2

[0082]Add phenolphthalein (7.95g, 0.025mol), resorcinol (7.80g, 0.075mol), triethylamine (20.2g, 0.2mol), 1-methylimidazole into a three-necked flask equipped with a condenser and a stirrer 0.25g, 150ml of dichloromethane, mixed and stirred for 0.5h, dropwise added phenyl dichlorophosphate (21.95, 0.105mol), controlled the rate of addition, dropped after 2h, then continued to react for 3h, added phenol (0.94g, 0.010mol) , continue to react overnight. After the reaction, add 300ml of deionized water, stir for 0.5h, adjust the pH of the water phase to about 7, separate the organic phase, pour it into 500ml of petroleum ether to obtain a fibrous sticky solid, dry it in vacuum at 100°C to obtain a transparent glass Solid phenolphthalein / resorcinol / phenyl dichlorophosphate ternary co-condensation polymer, denoted as sample 2 # .

[0083] sample 2 # The chemical structure formula is:

[0084]

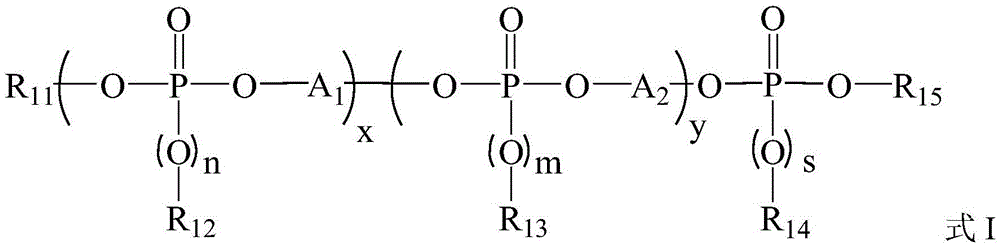

[0085] That is, in formula I: n, m, s=1; y / x=3; R 11 , R 12 , R 13 , R 14 and ...

Embodiment 3

[0087] Add phenolphthalein (15.9g, 0.050mol), resorcinol (0.52g, 0.050mol), triethylamine (20.2g, 0.2mol) and 1-methylimidazole into a three-necked flask equipped with a condenser and a stirrer 0.25g, 150ml of dichloromethane, mixed and stirred for 0.5h, dropwise added phenyl dichlorophosphate (21.95g, 0.105mol), controlled the rate of addition, 2h dripped, then continued to react for 3h, added phenol (0.94g, 0.010mol ), and continue to react overnight. After the reaction, add 300ml of deionized water, stir for 0.5h, adjust the pH of the water phase to about 7, separate the organic phase, pour it into 500ml of petroleum ether to obtain a fibrous sticky solid, dry it in vacuum at 100°C to obtain a transparent glass Solid phenolphthalein / resorcinol / phenyl dichlorophosphate ternary co-condensation polymer, denoted as sample 3 # .

[0088] sample 3 # The chemical structure formula is:

[0089]

[0090] That is, in formula I: n, m, s=1; y / x=1; R 11 , R 12 , R 13 , R 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com