Preparation method of luminous composite for sole material

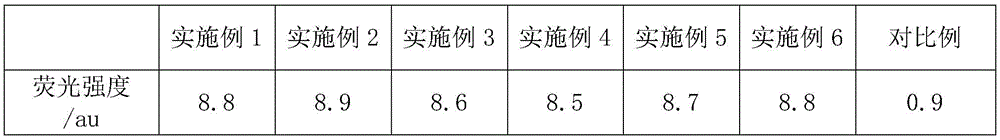

A technology for composite materials and sole materials, applied in the field of materials, can solve the problems of difficulty in producing luminous effects and poor luminous effects, and achieve the effects of improving luminous performance, enhancing luminous intensity and prolonging luminous time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare the luminescent composite material for shoe sole materials according to the following steps:

[0025] (1) Add zirconium nitrate, barium nitrate and lanthanum nitrate to deionized water, stir until they are evenly mixed, add butyl titanate and stir evenly, add 15% potassium hydroxide solution, zirconium nitrate, barium nitrate, nitric acid The weight ratio of lanthanum, deionized water, butyl titanate, and potassium hydroxide solution is 50:50:1:500:10:100. After heating to 70℃, magnetically stir for 40 minutes, then pour into the lining with polytetrafluoroethylene Put the hydrothermal reaction kettle in an oven, keep it at 180°C for 30 hours, take it out, cool it naturally to room temperature, wash the product repeatedly with deionized water and absolute ethanol, and place it in a drum after centrifugation. Dry to constant weight at 180°C in an air drying oven to obtain composite luminescent powder;

[0026] (2) Add the composite luminescent powder obtained in step...

Embodiment 2

[0030] (1) Add zirconium nitrate, barium nitrate and lanthanum nitrate to deionized water, stir until they are evenly mixed, add butyl titanate and stir evenly, add 15% potassium hydroxide solution, zirconium nitrate, barium nitrate, nitric acid The weight ratio of lanthanum, deionized water, butyl titanate, and potassium hydroxide solution is 50:50:1:500:10:100. After heating to 70℃, magnetically stir for 40 minutes, then pour into the lining with polytetrafluoroethylene Put the hydrothermal reaction kettle in an oven, keep it at 180°C for 30 hours, take it out, cool it naturally to room temperature, wash the product repeatedly with deionized water and absolute ethanol, and place it in a drum after centrifugation. Dry to constant weight at 180°C in an air drying oven to obtain composite luminescent powder;

[0031] (2) Add the composite luminescent powder obtained in step (1) to absolute ethanol, and ultrasonically disperse for 1 hour to obtain a mixed solution with a mass fract...

Embodiment 3

[0035] Prepare the luminescent composite material for shoe sole materials according to the following steps:

[0036] (1) Add zirconium nitrate, barium nitrate and lanthanum nitrate to deionized water, stir until they are evenly mixed, add butyl titanate and stir evenly, add 15% potassium hydroxide solution, zirconium nitrate, barium nitrate, nitric acid The weight ratio of lanthanum, deionized water, butyl titanate, and potassium hydroxide solution is 50:50:1:500:10:100. After heating to 70℃, magnetically stir for 40 minutes, then pour into the lining with polytetrafluoroethylene Put the hydrothermal reaction kettle in an oven, keep it at 180°C for 30 hours, take it out, cool it naturally to room temperature, wash the product repeatedly with deionized water and absolute ethanol, and place it in a drum after centrifugation. Dry to constant weight at 180°C in an air drying oven to obtain composite luminescent powder;

[0037] (2) Add the composite luminescent powder obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com