VCI powder zinc-rich paint for protecting surface of steel structure and preparation method thereof

A steel structure and powder technology, which is applied in the field of VCI powder zinc-rich coatings for steel structure surface protection and its preparation, can solve the problems of increasing project cost, waste of zinc resources, and lack of electrochemical cathodic protection, etc., to reduce the dispersion speed , good corrosion inhibition, excellent protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

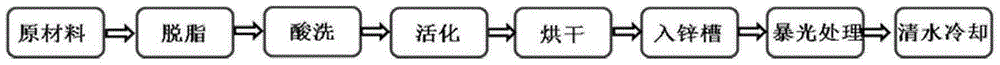

Method used

Image

Examples

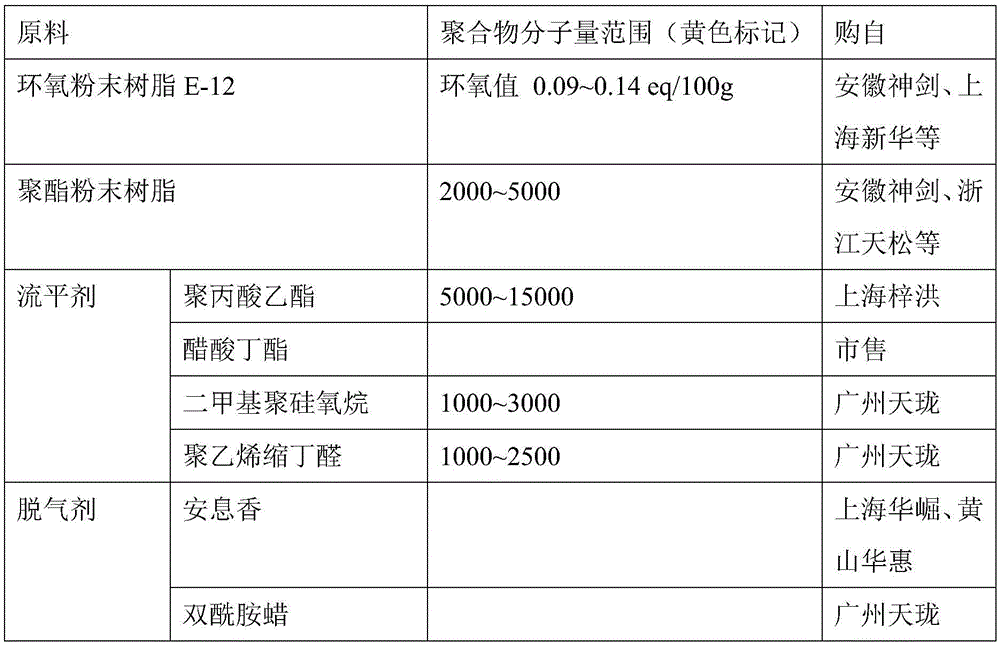

Embodiment 1

[0047] The VCI powder zinc-rich paint for steel structure surface protection includes the following components by weight: including base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; the base material includes 20 parts of epoxy powder resin E-12, 50 part of polyester powder resin T940; the filler includes 30 parts of flake zinc powder, 10 parts of aluminum tripolyphosphate, and 10 parts of zinc phosphate; the auxiliary agent is a leveling agent, a conductive agent, One or more of the degassing agent; the mass ratio of the base material and the filler is 3:7; the quality of the VCI gas phase corrosion inhibitor is 10% of the total mass of the base material and the filler; The mass is 2% of the total mass of base material and filler.

[0048] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black; the degassing agent is benzoin, bisamide wax; the ...

Embodiment 2

[0057] The VCI powder zinc-rich paint for steel structure surface protection includes the following components by weight: including base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; the base material includes 50 parts of epoxy powder resin E-12, 30 part of polyester powder resin T9401; the filler includes 60 parts of flake zinc powder, 5 parts of aluminum tripolyphosphate, and 5 parts of zinc phosphate; the auxiliary agent is a leveling agent, a conductive agent, a One or more of the degassing agent; the mass ratio of the base material and the filler is 3:1; the quality of the VCI gas phase corrosion inhibitor is 5% of the total mass of the base material and the filler; the auxiliary agent The mass is 10% of the total mass of base material and filler.

[0058] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black; the degassing agent is benzoi...

Embodiment 3

[0067] The VCI powder zinc-rich paint for steel structure surface protection includes the following components by weight: including base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; the base material includes 40 parts of epoxy powder resin E-12, 40 part of polyester powder resin T9401; the filler includes 45 parts of flake zinc powder, 7 parts of aluminum tripolyphosphate, and 8 parts of zinc phosphate; the auxiliary agent is a leveling agent, a conductive agent, and a One or more of the degassing agent; the mass ratio of the base material and the filler is 3:4; the quality of the VCI gas phase corrosion inhibitor is 7% of the total mass of the base material and the filler; The mass is 6% of the total mass of base material and filler.

[0068] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black; the degassing agent is benzoin and bisamide wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com