A personal energy management device with fluorine-containing silane hydrophobic surface layer and its preparation and application

An energy management device, fluorine-containing silane technology, applied in fiber processing, textiles and papermaking, fiber types, etc., can solve problems such as poor portability, uneven heating, uncontrollable temperature, etc., to avoid energy waste and reduce heat radiation loss , Improve the effect of output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

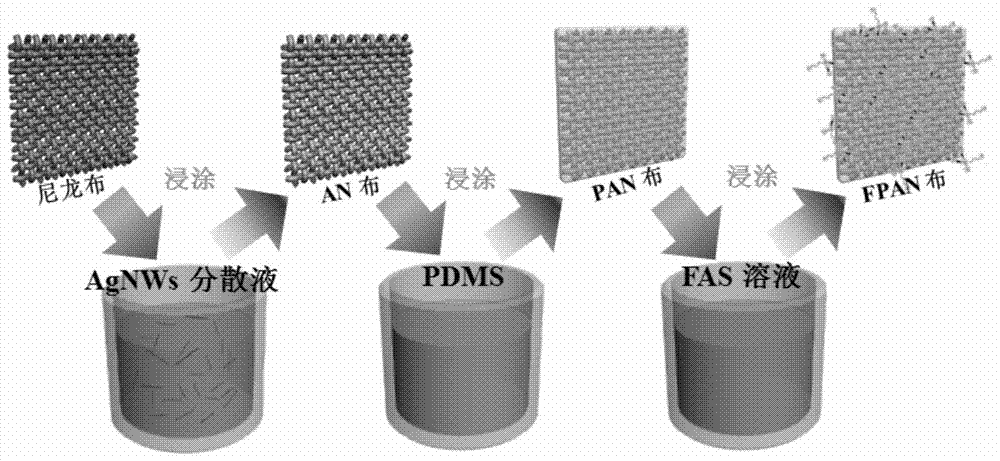

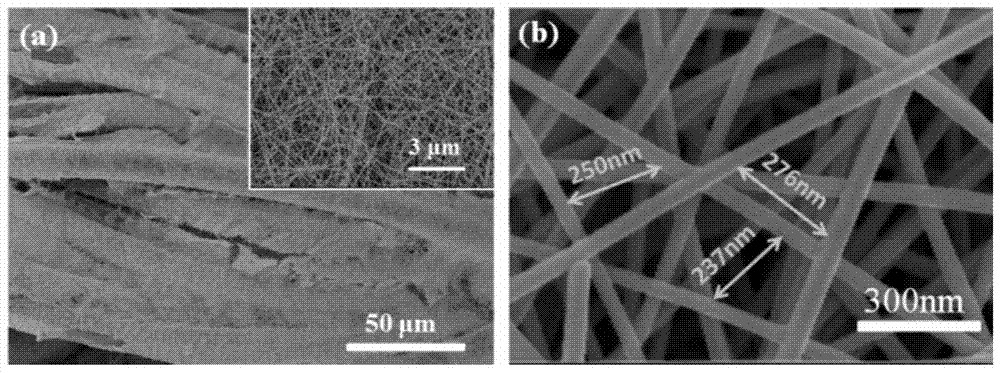

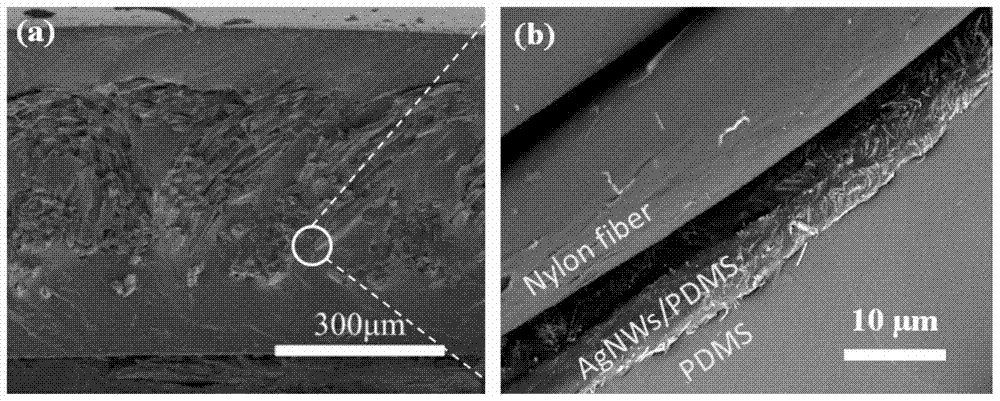

[0037] Divide 3.0×3.0cm 2 Nylon cloth is soaked in silver nanowire ethanol solution, then taken out and dried in a vacuum oven. Repeat this process until the silver nanowire loading is 0.9mg / cm 2AN cloth. The above-mentioned AN cloth was immersed in PDMS, and the AN cloth uniformly coated with PDMS was taken out and cured in an oven to obtain a PAN cloth with a coating thickness of 240 μm. FAS was mixed with isopropanol and then hydrolyzed by adding HCl solution to obtain a mixed solution of FAS isopropanol and water with a mass fraction of 1.26%. Put the PAN cloth into a plasma processor with a power of 200W for 5 minutes and then immerse it in the obtained FAS solution for 1 hour, take it out and dry it in an oven. figure 1 Schematic diagram of the preparation process. figure 2 It can be seen that the silver nanowires are uniformly distributed on the nylon cloth. The distance between the nanowires is about 300nm, which is much smaller than the wavelength (9μm) of infra...

Embodiment 2

[0039] Divide 3.0×3.0cm 2 Nylon cloth is soaked in silver nanowire ethanol solution, then taken out and dried in a vacuum oven. Repeat this process until the silver nanowire loading is 0.7mg / cm 2 AN cloth. The above-mentioned AN cloth was immersed in PDMS, and the AN cloth uniformly coated with PDMS was taken out and cured in an oven to obtain a PAN cloth with a coating thickness of 240 μm. FAS was mixed with isopropanol and then hydrolyzed by adding HCl solution to obtain a mixed solution of FAS isopropanol and water with a mass fraction of 1.26%. Put the PAN cloth into a plasma processor with a power of 200W for 5 minutes and then immerse it in the obtained FAS solution for 1 hour, take it out and dry it in an oven. The reduction of silver nanowire content will not only lead to uneven distribution of nanowires on the surface of nylon cloth, which will affect its thermal insulation performance; it will also increase the resistance of AN cloth, resulting in a decrease in its...

Embodiment 3

[0041] Divide 3.0×3.0cm 2 Nylon cloth is soaked in silver nanowire ethanol solution, then taken out and dried in a vacuum oven. Repeat this process until the silver nanowire loading is 1.5mg / cm 2 AN cloth. The above-mentioned AN cloth was immersed in PDMS, and the AN cloth uniformly coated with PDMS was taken out and cured in an oven to obtain a PAN cloth with a coating thickness of 240 μm. FAS was mixed with isopropanol and then hydrolyzed by adding HCl solution to obtain a mixed solution of FAS isopropanol and water with a mass fraction of 1.26%. Put the PAN cloth into a plasma processor with a power of 200W for 5 minutes and then immerse it in the obtained FAS solution for 1 hour, take it out and dry it in an oven. Excessive silver nanowire content has little effect on device performance, but increases the preparation time and the amount of silver nanowire, resulting in increased device cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com