A visible light-responsive composite catalyst for degrading organic pollutants in saline wastewater and its preparation method

A technology of organic pollutants and composite catalysts, applied in water pollutants, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve surface active site occupation, catalytic activity reduction, disappearance, etc. problem, to achieve the effect of simple method, simple synthesis process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

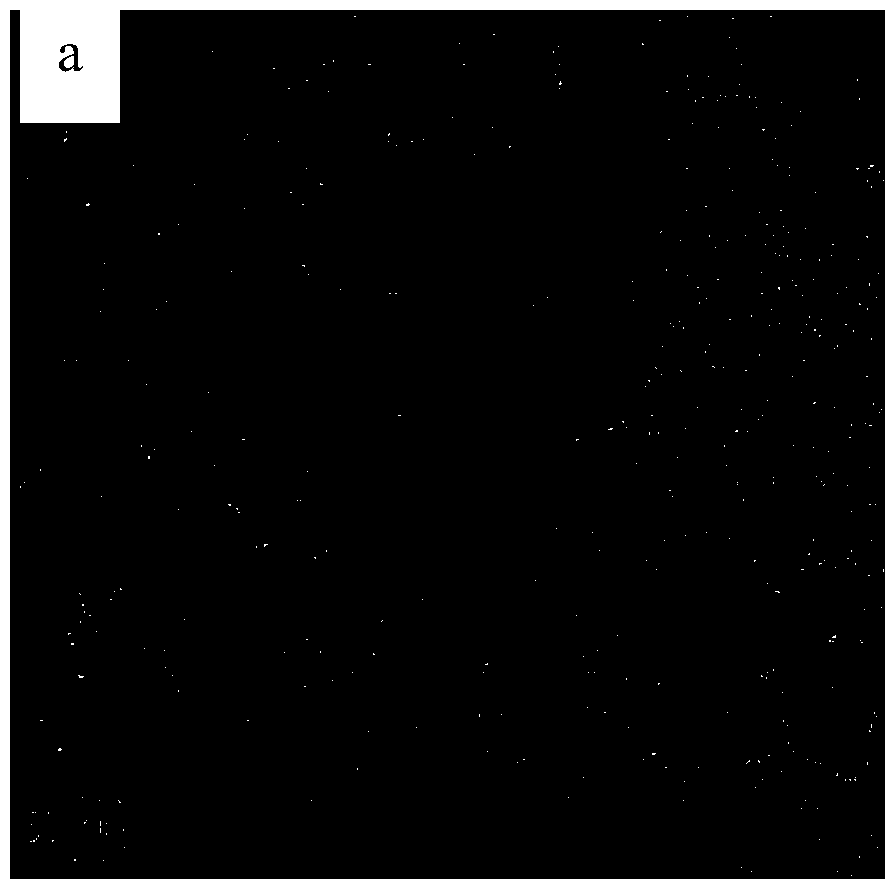

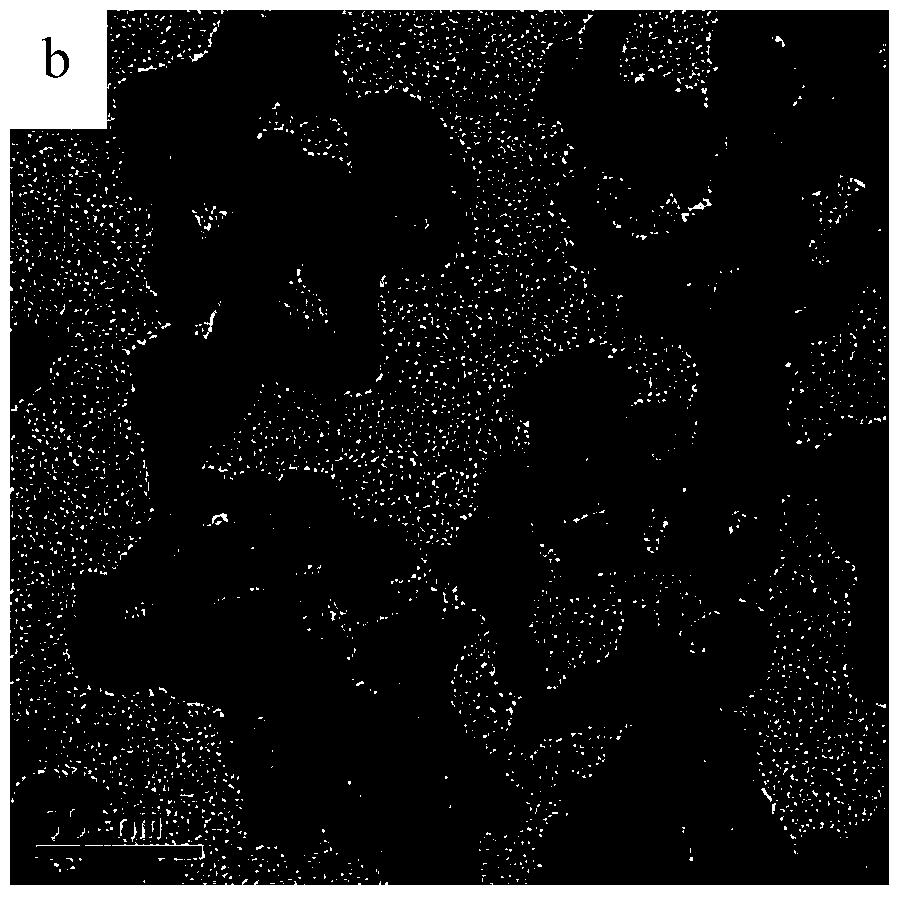

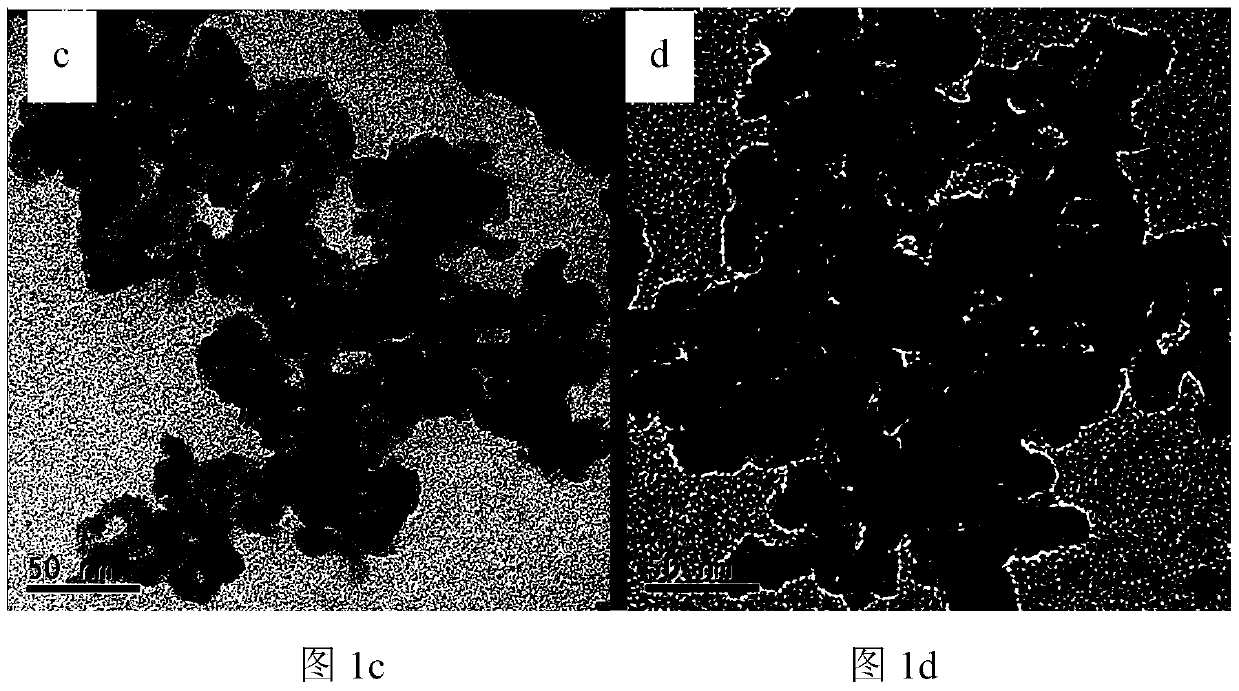

Image

Examples

Embodiment 1

[0040] (1) Catalyst preparation

[0041] Get 0.5g of silicon dioxide with hydrophilic surface (specific surface area 180m 2 / g), 200mL of absolute ethanol and 2mL of NaOH aqueous solution (10g / L) were placed in a flask, stirred and adsorbed in a 30°C water bath. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0042] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate and 9 mg of ferric nitrate were dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Butyl titanate undergoes hydrolysis reaction in the adsorption water layer, and iron ions undergo precipitation reaction with hydroxide ions in the adsorption water layer, finally generating Fe(OH) 3 -TiO 2 , after the completion of the reaction for 5 hours, a suspension system containing composite particles was obtained.

[0043] Add the suspension system after the reacti...

Embodiment 2

[0053] (1) Catalyst preparation

[0054] Get 0.5g of silicon dioxide with hydrophilic surface (the specific surface area is 180m 2 / g), 200mL absolute ethanol and 2mL NaOH aqueous solution (10g / L) were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0055] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate and 27 mg of ferric nitrate were dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Butyl titanate undergoes hydrolysis reaction in the adsorption water layer, and iron ions undergo precipitation reaction with hydroxide ions in the adsorption water layer, finally generating Fe(OH) 3 -TiO 2 , after the completion of the reaction for 5 hours, a suspension system containing composite particles was obtained.

[0056] Add the suspension system after the r...

Embodiment 3

[0066] (1) Catalyst preparation

[0067] Get 0.5g of silicon dioxide with hydrophilic surface (the specific surface area is 180m 2 / g), 200mL absolute ethanol and 2mL NaOH aqueous solution (10g / L) were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0068] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate and 54 mg of ferric nitrate were dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Butyl titanate undergoes hydrolysis reaction in the adsorption water layer, and iron ions undergo precipitation reaction with hydroxide ions in the adsorption water layer, finally generating Fe(OH) 3 -TiO 2 , after the completion of the reaction for 5 hours, a suspension system containing composite particles was obtained.

[0069] Add the suspended system after the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com