Material for removing nitrates in water by autotrophic microbe denitrification process

A technology of autotrophic microorganisms and denitrification, applied in biological water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of microbial metabolism inhibition, system alkalinity drop, poor treatment effect, etc., to achieve Improve efficiency, high removal efficiency, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

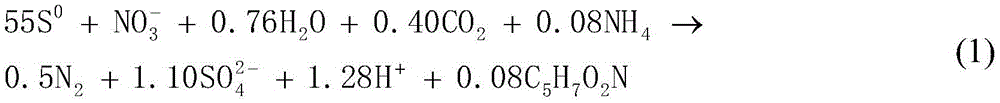

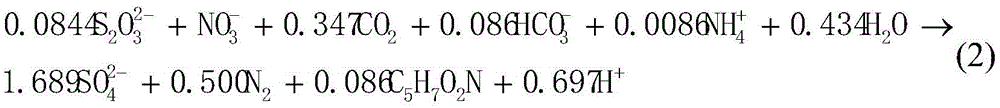

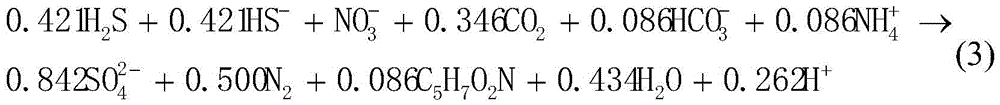

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the autotrophic microbial denitrification method is used to remove nitrate in water, and the material is 3mm granular in particle size; the material contains elemental sulfur and calcium carbonate, and the mass ratio of the elemental sulfur to calcium carbonate is 2.5 1: 20-100 mesh limestone powder is used as raw material to form the calcium carbonate in the material.

[0039] The preparation method of the material for removing nitrate in water by the autotrophic microbial denitrification method in this embodiment, the specific operation steps are:

[0040] 1) Use tinfoil to weigh 25.0g elemental sulfur powder, fold the four edges of the tinfoil into a carton shape, place the elemental sulfur to liquefy and flow out, then place the tinfoil and elemental sulfur powder together on a constant temperature electric heating plate to Raise the temperature to 105°C at a heating rate of 5°C / min to completely melt the elemental sulfur and obtain liquid sulfur...

Embodiment 2

[0044] In this embodiment, the autotrophic microbial denitrification method is used to remove nitrate in water, and the material is 1mm granular in particle size; the material contains elemental sulfur and calcium carbonate, and the mass ratio of the elemental sulfur to calcium carbonate is 3.0 : 1; 20-100 mesh egg shell powder is used as raw material to form the calcium carbonate in the material.

[0045] The preparation method of the material for removing nitrate in water by the autotrophic microbial denitrification method in this embodiment, the specific operation steps are:

[0046] 1) Use tinfoil to weigh 30.0g elemental sulfur powder, fold the four edges of the tinfoil into a carton shape, place the elemental sulfur to liquefy and flow out, then place the tinfoil and elemental sulfur powder together on a constant temperature electric heating plate to Raise the temperature to 110°C at a heating rate of 7°C / min to completely melt the elemental sulfur and obtain liquid sulf...

Embodiment 3

[0050] In this embodiment, the autotrophic microbial denitrification method is used to remove nitrate in water, and the material is 5mm granular in particle size; the material contains elemental sulfur and calcium carbonate, and the mass ratio of the elemental sulfur to calcium carbonate is 1.25 : 1; 20-100 mesh scallop shell powder is used as raw material to form the calcium carbonate in the material.

[0051] The preparation method of the material for removing nitrate in water by the autotrophic microbial denitrification method in this embodiment, the specific operation steps are:

[0052] 1) Use tinfoil to weigh 25.0g elemental sulfur powder, fold the four edges of the tinfoil into a carton shape, place the elemental sulfur to liquefy and flow out, then place the tinfoil and elemental sulfur powder together on a constant temperature electric heating plate to Raise the temperature to 115°C at a heating rate of 10°C / min to completely melt the elemental sulfur and obtain liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com