Treatment method for modifying titanium boride ceramic surface by using silane coupling agent

A technology of silane coupling agent and ceramic surface, which is applied in the field of treatment of titanium boride ceramic surface modified by silane coupling agent, can solve the problem of the absence of hydroxyl groups that can interact with the coupling agent, so as to improve the bonding performance and solve the problem of Interfacial wettability and compatibility issues, significant treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A treatment method for modifying the surface of titanium boride ceramics with a silane coupling agent, comprising the steps of:

[0023] 1) Surface oxidation etching of titanium boride ceramics:

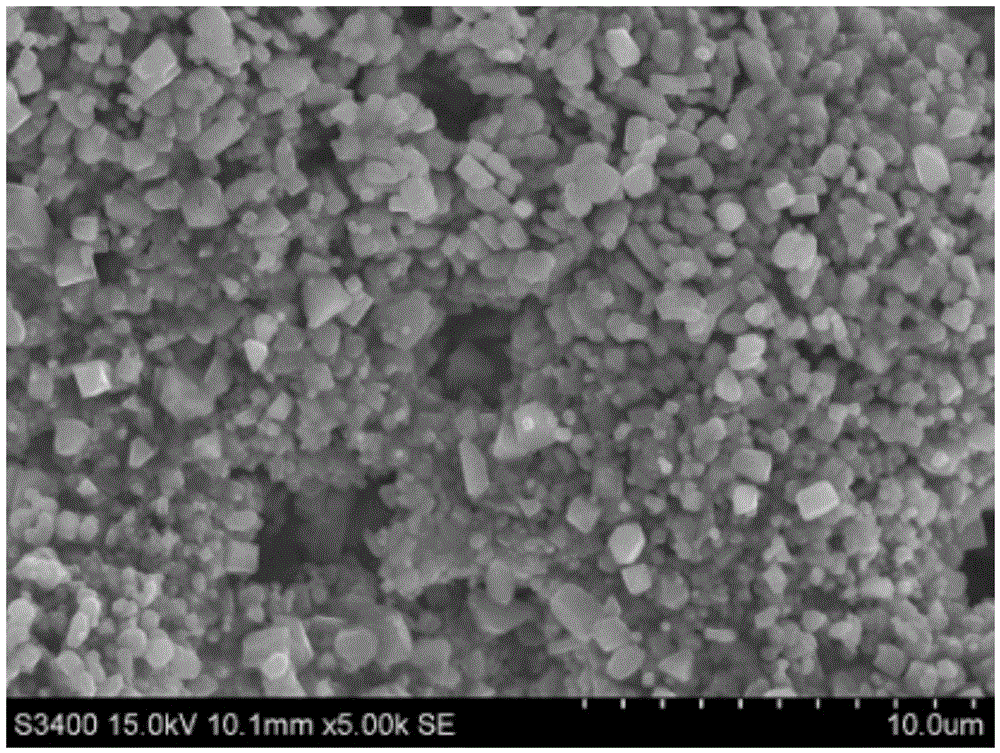

[0024] Take TiB with a thickness of 2mm cut by an EDM 2 The ceramic sheet was ultrasonically oscillated in acetone for 20 minutes to remove oil stains and sundries existing on the ceramic surface during processing, and then dried to obtain TBC-1. Put TBC-1 in a muffle furnace for oxidation etching, the heating rate is 10°C / min, the holding temperature is 800°C, the holding time is 2h, and it is naturally cooled to room temperature to obtain a ceramic covered with a yellow oxide film. Washed with deionized water and dried to obtain TBC-2. The surface morphology of TBC-2 is as follows figure 1 shown.

[0025] 2) Take 36ml of ethanol and 4ml of deionized water, mix them, then add 10ml of silane coupling agent KH-550, use a magnetic stirrer to stir at room temperature for 20mi...

Embodiment 2

[0029] A treatment method for modifying the surface of titanium boride ceramics with a silane coupling agent, comprising the steps of:

[0030] 1) Surface oxidation etching of titanium boride ceramics:

[0031] Take TiB with a thickness of 2mm cut by an EDM 2 The ceramic sheet was ultrasonically oscillated in acetone for 10 minutes to remove oil stains and sundries existing on the ceramic surface during processing, and then dried to obtain TBC-1. Put TBC-1 in a muffle furnace for oxidation etching, the heating rate is 10°C / min, the holding temperature is 600°C, the holding time is 1h, and naturally cooled to room temperature to obtain a ceramic covered with a light yellow oxide film. Wash with deionized water and dry to obtain TBC-2.

[0032] 2) Take 32ml of methanol and 4ml of deionized water, mix them, then add 3.6ml of silane coupling agent KH560, use a magnetic stirrer to stir at room temperature for 20min, mix well, so that the silane coupling agent is completely hydrol...

Embodiment 3

[0036] A treatment method for modifying the surface of titanium boride ceramics with a silane coupling agent, comprising the steps of:

[0037] 1) Surface oxidation etching of titanium boride ceramics:

[0038] Take TiB with a thickness of 2mm cut by an EDM 2 The ceramic sheet was ultrasonically oscillated in acetone for 30 minutes to remove oil stains and sundries existing on the ceramic surface during processing, and dried to obtain TBC-1. Put TBC-1 in a muffle furnace for oxidation etching, the heating rate is 10°C / min, the holding temperature is 1000°C, the holding time is 3h, and it is naturally cooled to room temperature to obtain a ceramic covered with a yellow oxide film. Washed with deionized water and dried to obtain TBC-2.

[0039] 2) Take 40ml of isopropanol and 4ml of deionized water, mix them, then add 8.8ml of silane coupling agent KH550, use a magnetic stirrer to stir at room temperature for 20min, mix well, so that the silane coupling agent is completely hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com