A kind of preparation method of pear gum polysaccharide

The technology of jujube gum and jujube gum is applied in the directions of skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., and can solve the problems of difficult implementation and high viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

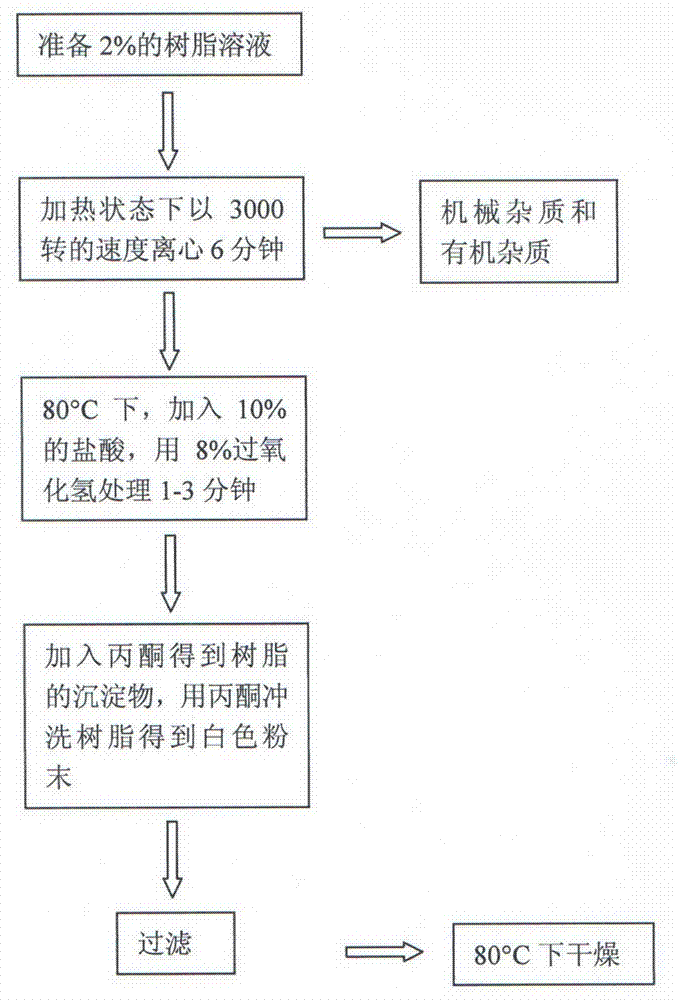

Method used

Image

Examples

Embodiment 1

[0036] a. Collect 100 grams of Elaeagnus eraefolia gum from August to September every summer, and then dry it naturally in a cool place and then crush it with a stainless steel shaker screw type small grinder. The crushing time is 60 seconds, and a round stainless steel mesh is used. Sieve and filter 100 mesh, separate impurity, obtain gum powder;

[0037] b. The gum powder obtained in step a is prepared with distilled water to form a gum solution with a concentration of 0.1%;

[0038]c. Heat the gum solution in step b to dissolve the gum on the electric heating mantle, and centrifuge at a speed of 1000r / min for 2 minutes while keeping warm, separate and remove mechanical impurities and organic impurities, and obtain the gum solution for subsequent use;

[0039] d. Heating the gum solution in step c to a temperature of 80° C., stirring and adding hydrochloric acid with a volume concentration of 8% dropwise, and then decolorizing with hydrogen peroxide with a volume concentrati...

Embodiment 2

[0042] a. Collect 100 grams of Elaeagnus eraefolia gum from August to September every summer, dry it naturally in the shade, and then crush it with a stainless steel screw-type small grinder. The crushing time is 80 seconds, and the round stainless steel is used. Filter 200 meshes through a mesh sieve to separate foreign matter to obtain gum powder;

[0043] b. The gum powder obtained in step a is prepared with distilled water to form a gum solution with a concentration of 2%;

[0044] c. Heat the gum solution in step b to dissolve the gum on the electric heating mantle, and centrifuge at a speed of 5000r / min for 3 minutes in a state of heat preservation, separate and remove mechanical impurities and organic impurities, and obtain the gum solution for subsequent use;

[0045] d. Heat the gum solution in step c to a temperature of 80° C., add hydrochloric acid with a concentration of 8% dropwise with stirring, and then treat it with hydrogen peroxide with a volume concentration...

Embodiment 3

[0048] a. Collect 100 grams of Elaeagnus eraefolia gum from August to September every summer, dry it naturally in the shade, and then crush it with a small stainless steel screw-type grinder. The crushing time is 100 seconds, and the round stainless steel is used. Filter 300 meshes with a mesh sieve to separate foreign matter to obtain gum powder;

[0049] b. The gum powder obtained in step a is prepared with distilled water to form a gum solution with a volume concentration of 3%;

[0050] c. Heat the gum solution in step b to dissolve the gum on the electric heating mantle, and centrifuge it at a speed of 8000r / min for 6 minutes while keeping warm, separate and remove mechanical impurities and organic impurities, and obtain the gum solution for subsequent use;

[0051] d. Heating the gum solution in step c to a temperature of 80° C., stirring and adding hydrochloric acid with a concentration of 10% dropwise, and then treating it with hydrogen peroxide with a volume concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com