Gas insulated electrical equipment partial discharge multi-source combined monitoring experiment device

A technology of partial discharge and gas discharge, applied in measuring devices, measuring current/voltage, measuring electricity, etc., can solve problems such as insufficient monitoring information, and achieve high detection sensitivity, good selectivity and precision, and high scalability value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

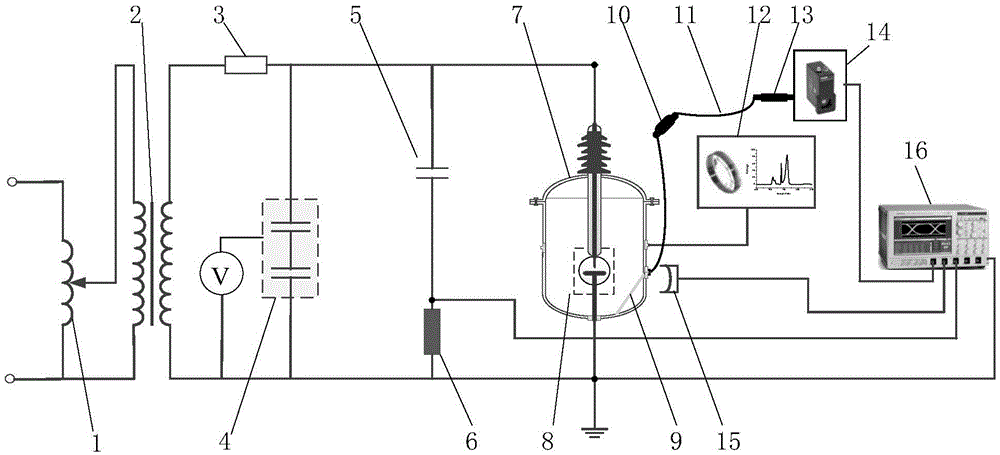

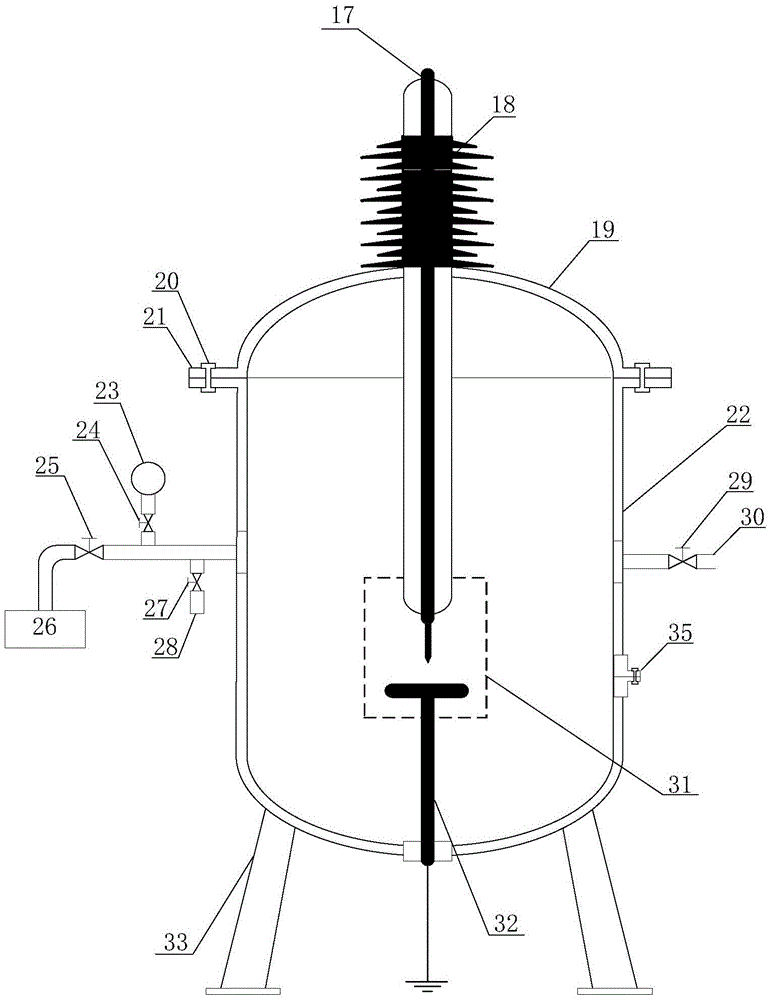

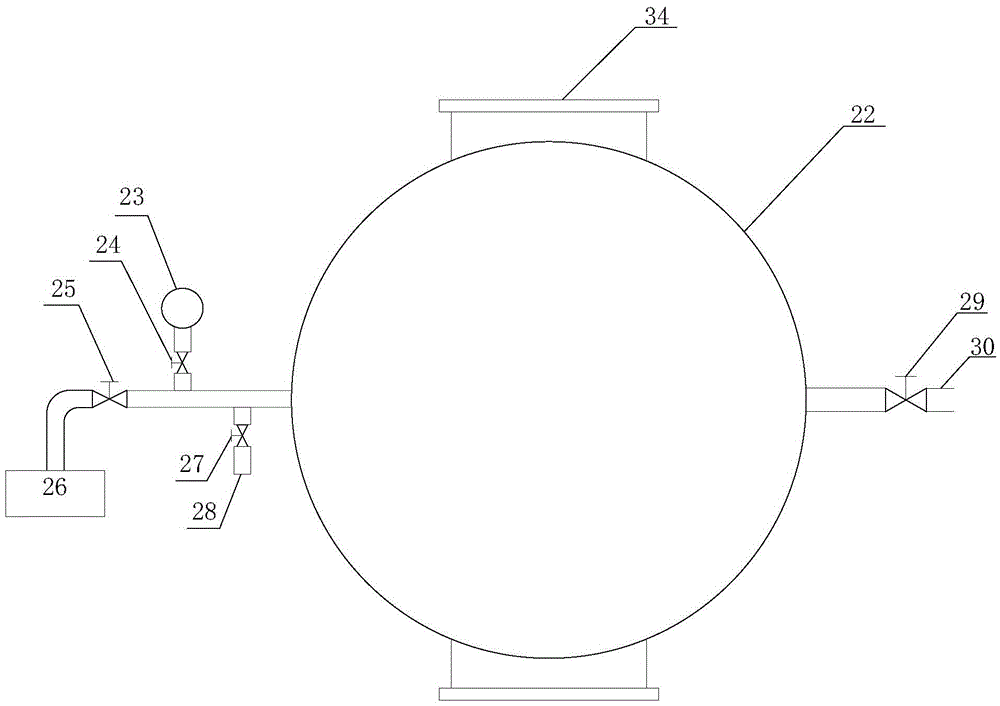

[0030] In the figure: 1. Power supply voltage regulating console, 2. No partial discharge power frequency test transformer, 3. No partial discharge protection resistor, 4. Power frequency capacitor voltage divider, 5. Coupling capacitor, 6. Detection impedance, 7. Gas discharge chamber, 8. Artificial insulation defect model, 9. Fluorescent optical fiber sensor, 10. Optical fiber coupler, 11. Ordinary optical fiber, 12. Gas chromatography mass spectrometer, 13. Optical fiber adapter, 14. Photomultiplier tube, 15. UHF microstrip antenna, 16. digital storage oscilloscope, 17. high-voltage guide rod, 18. high-voltage bushing, 19 ellipsoidal top cover, 20. screw, 21. flange, 22. stainless steel columnar cavity, 23. vacuum Pressure gauge, 24, vacuum pressure gauge ball valve, 25, vacuum pump ball valve, 26, vacuum pump, 27, sampling ball valve, 28, sampling port, 29, sampling ball valve, 30, sampling port, 31, artificial insulation defect, 32, grounding Conductive rod, 33, supportin...

Embodiment 2

[0037] An experimental device for multi-sensor joint monitoring of partial discharge of gas-insulated electrical equipment is the same as in Example 1, wherein: the capacity of the power regulator console 1 is 50kVA, the input voltage is 380V, and the output voltage is 0-400V. The non-PD test transformer 2 is 100kV / 50kVA. The protection resistor 3 is 100kΩ / 0.3A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thread length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com