Bacillus thuringiensis floating sustained-release tablet and preparation method thereof

A technology of Bacillus thuringiensis and Bacillus thuringiensis, which is applied in the field of Bacillus thuringiensis sustained-release floating tablet and its preparation, can solve the problems of inconvenient use of wettable powder, instability of liquid preparation, and difficulty in forming a scale, so as to reduce dosage The number of times, good stability, and the effect of reducing the release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

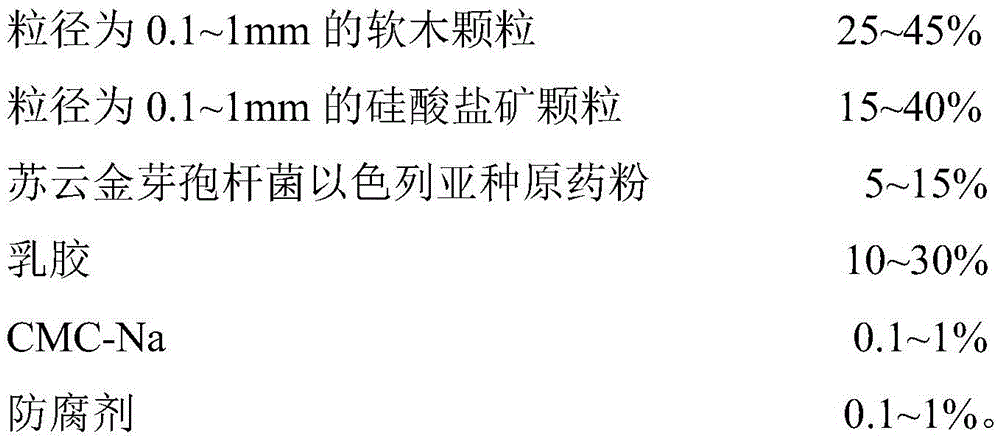

[0019] A Bacillus thuringiensis slow-release floating tablet, which is made of the following ingredients in proportion by weight:

[0020]

[0021] Raw material description:

[0022] (1) Cork granules: peel off the outer brown layer of the thick bark, and pulverize the inner light yellow or off-white soft bark layer through a blade grinder, and sieve the granules with a diameter of 0.1 to 1 mm for later use;

[0023] (2) Kaolinite granules: kaolinite is prepared into light porous materials by high-temperature calcination process, and after crushing and screening, take 0.1-1mm diameter particles for later use;

[0024] (3) Bacillus thuringiensis subspecies Israel technical powder: purchased through commercial channels, the biological potency is greater than 6500ITU / mg.

[0025] The preparation process is as follows:

[0026] 1) Grinding 10Kg of Bacillus thuringiensis subsp. Israelite technical powder to 200-700 mesh by airflow, and then mixing with 39Kg of cork particles a...

Embodiment 2

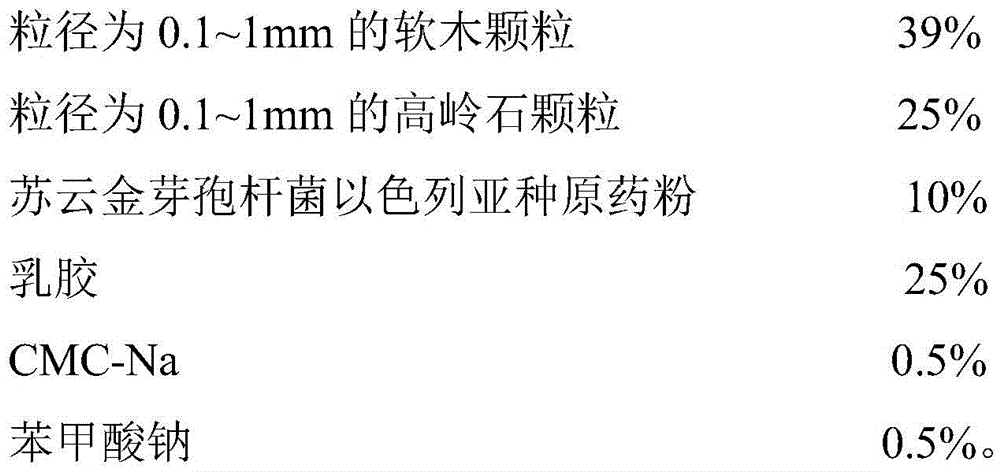

[0030] A bacillus thuringiensis slow-release floating tablet, which consists of the following ingredients in proportion by weight:

[0031]

[0032]

[0033] The preparation process is as follows:

[0034] 1) 5Kg of the original drug powder of Bacillus thuringiensis subsp. Israel was crushed to 200-700 mesh by airflow, and then mixed with 45Kg of cork particles and 18Kg of montmorillonite particles to obtain 68Kg of dry material;

[0035] 2) Swell CMC-Na1Kg with water into a sol with a weight content of 2%, then stir and mix with latex 30Kg to obtain 80Kg of mixed glue;

[0036] 3) Mix the dry material with the mixed glue, stir to make a soft material, and then use 0.5Kg / cm in the mold 2 The pressure is pressed into tablets, and after demoulding, it is dried until the moisture content is lower than 10%.

Embodiment 3

[0038] A bacillus thuringiensis slow-release floating tablet, which consists of the following ingredients in proportion by weight:

[0039]

[0040] The preparation process is as follows:

[0041] 1) 15Kg of the technical powder of Bacillus thuringiensis subsp. Israel is crushed by airflow to 200-700 mesh, and then mixed with 25Kg of cork particles and 40Kg of asbestos particles to obtain 80Kg of dry material;

[0042] 2) Swell CMC-Na0.1Kg with water into a sol with a weight content of 0.5%, then stir and mix with latex 19.8Kg to obtain 40Kg of mixed glue;

[0043] 3) Mix the dry material with the mixed glue, stir to make a soft material, and then use 2Kg / cm in the mold 2 The pressure is pressed into tablets, and after demoulding, it is dried until the moisture content is lower than 10%.

[0044] For detecting the mosquito-killing effect of the present invention, we drop into 100 2-year-old larvae of artificial rearing respectively in 4 1 ton airtight water-adding contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com