A kind of preparation method of synthesis gas catalyst by partial oxidation of methane

A technology of catalyst and synthesis gas, which is applied in the field of preparation of supported nickel-based catalysts for partial oxidation of methane to synthesis gas, which can solve the problems of little catalyst contribution, low metal utilization rate of carrier channels, and accelerated deep oxidation of products, so as to reduce catalyst cost, increased conversion and product selectivity, and the effect of avoiding further oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

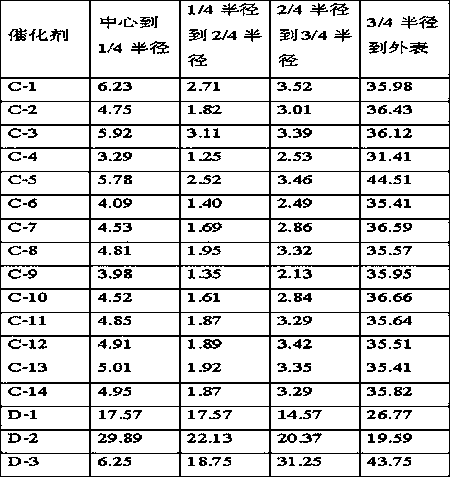

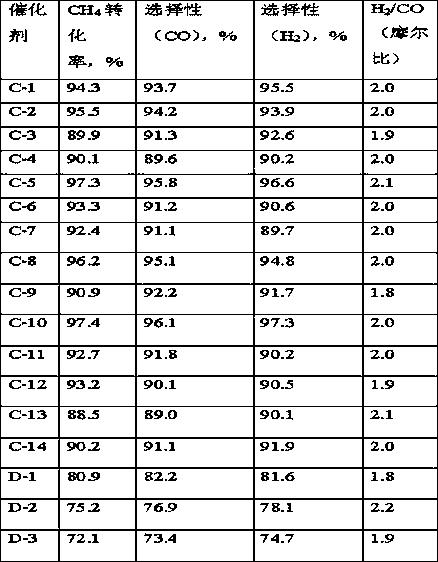

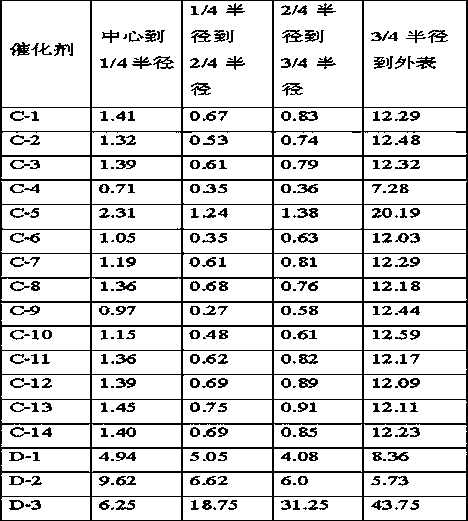

Image

Examples

Embodiment 1

[0029] (1) Preparation of carrier:

[0030] Weigh 85.28g of cetyltrimethylammonium bromide and 81.95g of citric acid, add 842mL of deionized water to make a mixed solution, add 292.6g of aluminum nitrate to the mixed solution, stir for 2h, and then stir at 70°C Until the gel is formed, the gel is aged at room temperature for 12 hours, then dried at 110°C for 8 hours, and calcined at 700°C for 4 hours to obtain an alumina carrier, in which citric acid: hexadecyltrimethylammonium bromide: aluminum element: The molar ratio of water is: 0.5:0.3:1:60. The nature of the carrier is: the specific surface area is 296m 2 / g, the pore volume is 0.65mL / g, and the average pore diameter is 9.8nm.

[0031] (2) Preparation of catalyst:

[0032]Weigh 1.32g of nickel nitrate and dissolve it in 15.5mL of deionized water to obtain solution A; load it on 20g of prepared alumina carrier by equal volume impregnation method, age at room temperature for 4h, dry at 80°C for 12h, and calcinate at 700...

Embodiment 2

[0034] Weigh 1.32g of nickel nitrate and dissolve it in 19.5mL of deionized water to obtain solution A; use the equal volume impregnation method to load 20g of hydrogen ZSM-5 (silicon-aluminum ratio 50, pore volume of 0.23ml / g, specific surface area of 426m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 6h, dried at 110°C for 10h, and calcined at 600°C for 4h to obtain catalyst precursor B, wherein Ni accounted for 1% of the catalyst weight in terms of elements; catalyst precursor B Activate in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 90%, the reduction conditions are 400°C, 0.2MPa (absolute pressure), and the reduction time is 8h; the mass concentration of the reduced and activated catalyst precursor B and 300mL is Add 10% sorbitol solution into the autoclave, seal it and replace it with hydrogen for 4 times, then adjust the hydrogen pressure to 2MPa, and react at 300°C for 2h; place the r...

Embodiment 3

[0036] (1) Preparation of carrier:

[0037] Weigh 72.2g cetyltrimethylammonium bromide and 69.4g citric acid, add 712mL deionized water to make a mixed solution, add 178mL tetraethyl orthosilicate to the mixed solution, stir for 2h, and then Stir at ℃ until it forms a gel, age the gel at room temperature for 12h, then dry at 110°C for 8h, and calcinate at 600°C for 3h to obtain a silica carrier, in which citric acid: hexadecyltrimethylammonium bromide: The molar ratio of silicon element: water is: 0.5:0.3:1:60. The nature of the carrier is: the specific surface area is 565m 2 / g, the pore volume is 0.68mL / g, and the average pore diameter is 5.2nm.

[0038] (2) Preparation of catalyst:

[0039] Weigh 1.32g of nickel nitrate and dissolve it in 13.5mL of deionized water to obtain solution A; load it on 20g of the prepared silica carrier by equal volume impregnation method, age at room temperature for 8h, dry at 120°C for 6h, and calcinate at 600°C for 4h to obtain the catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com