Visible-light catalytic film with dual oxygen-assisted catalytic layers and preparation method and application thereof

A double oxygen-promoting catalytic layer and visible light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor stability, inconvenient recycling, and catalytic efficiency Low cost, high repeatability, good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The visible light catalytic thin film material (Fe 2 o 3 -FeOOH-NiOOH) preparation method comprises the steps:

[0045] (1) to contain Fe 2+ The precursor solution was used as the electrolyte, and a CHI660E electrochemical workstation was used to conduct electrodeposition using a three-electrode system, that is, clean conductive glass (FTO, commercially available) was used as the working electrode, the graphite electrode was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode. After the electrode is dried naturally, it is calcined at a constant temperature to obtain Fe 2 o 3 film;

[0046] Containing Fe in this implementation case 2+ The precursor solution of Fe 2+ The molar concentration is 0.02M. Prepared by the following method:

[0047] Weigh a certain amount of FeCl 2 4H 2 O is dissolved in a certain volume of ethylene glycol and distilled water, and the volume ratio of ethylene glycol to distilled water is 1:8.

...

Embodiment 2

[0061] The visible light catalytic thin film material (Fe 2 o 3 The application of -FeOOH-NiOOH) comprises the following steps:

[0062] (1) Use 1MH 2 SO 4 solution or 1M NaOH solution to adjust the pH value of artificial simulated wastewater to 3;

[0063] The artificial simulated wastewater in this embodiment is artificial simulated wastewater containing phenol, and its concentration is 10 mg / L.

[0064] (2) Build a photoelectric catalytic degradation system, with the catalytic material prepared by embodiment 1 as the photoanode, and the titanium sheet as the cathode, and process the artificial simulated wastewater after adjusting the pH;

[0065] During the photocatalysis, electrocatalysis and photoelectrocatalysis degradation in this embodiment, in order to ensure the uniform concentration of pollutants, it is stirred in the whole process; at the same time, when performing electrocatalysis and photoelectrocatalysis Apply a working voltage of 3V between;

[0066] In o...

Embodiment 3

[0071] Repeat the operation steps of Example 1, the difference is that the visible light catalytic thin film material (Fe 2 o 3 -FeOOH-NiOOH) in the process, step (2) is not implemented, that is, steps (1) and (3) are implemented to prepare Fe 2 o 3 –NiOOH catalytic film.

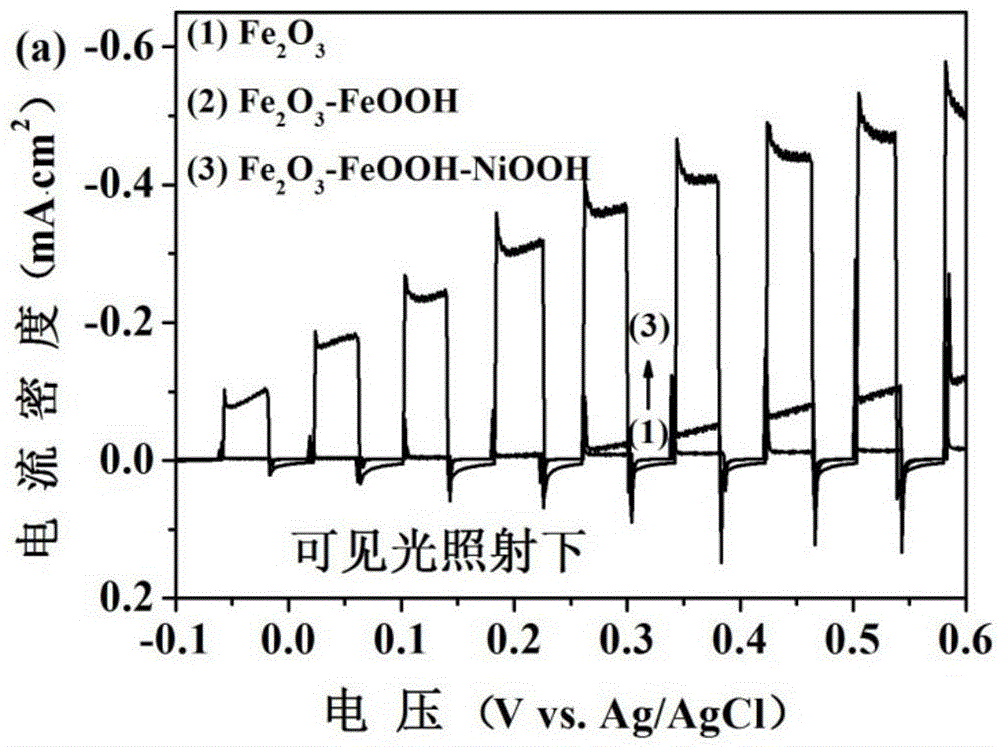

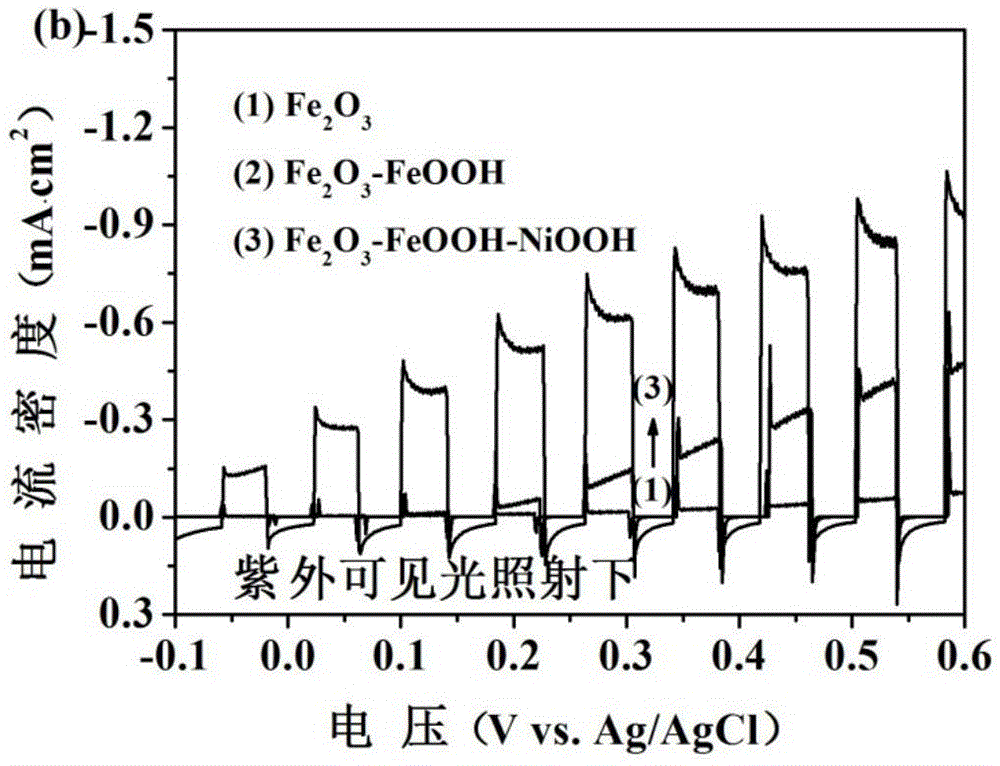

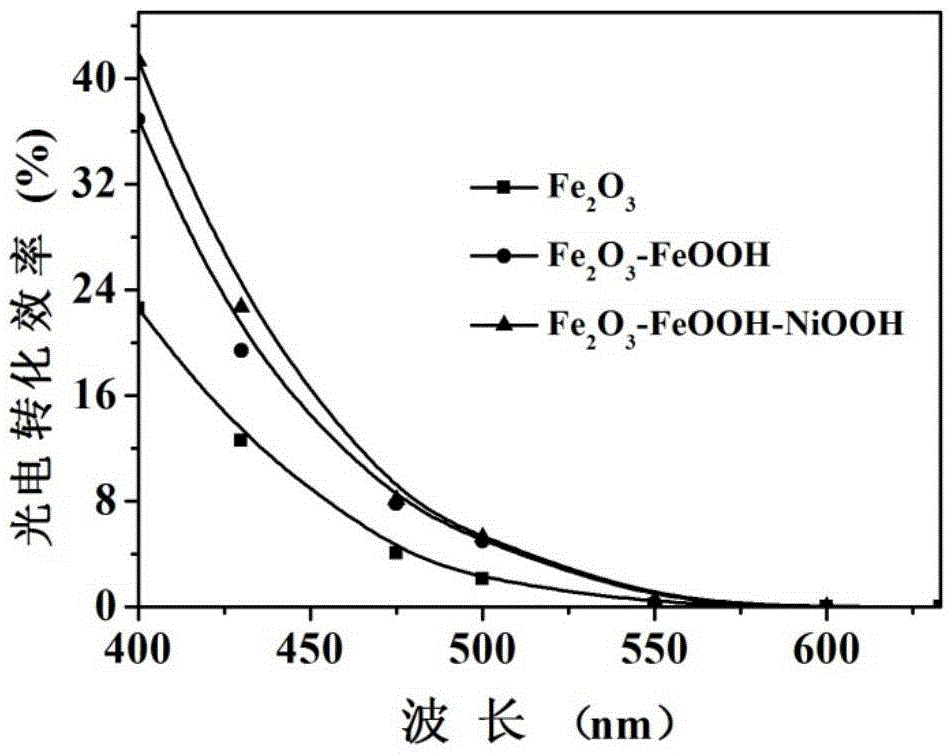

[0072] Fe prepared under the conditions of this embodiment case 2 o 3 -NiOOH catalytic film and the Fe prepared by the conditions of Example 1 2 o 3 -FeOOH-NiOOH, Fe 2 o 3 -FeOOH and Fe 2 o 3 Catalyzed thin films, further comparison of photoelectrochemical properties.

[0073] The Fe obtained in this implementation case 2 o 3 -NiOOH catalytic thin film photoelectrochemical performance is better than Fe prepared by embodiment 1 2 o 3 Thin film, but slightly inferior to Fe 2 o 3 -FeOOH catalytic film, and significantly inferior to Fe 2 o 3 -FeOOH-NiOOH catalytic thin film. Under visible light irradiation, when the voltage is 0.35Vvs.Ag / AgCl, Fe 2 o 3 -NiOOH to Fe 2 o 3 The photocurrent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com