Sulfur-tolerant shift catalyst circulating vulcanization process

A catalyst cycle and sulfur-resistant shift technology, which is applied in the coal chemical industry to achieve the effects of increasing the cyclic sulfurization rate, increasing the inlet temperature and reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

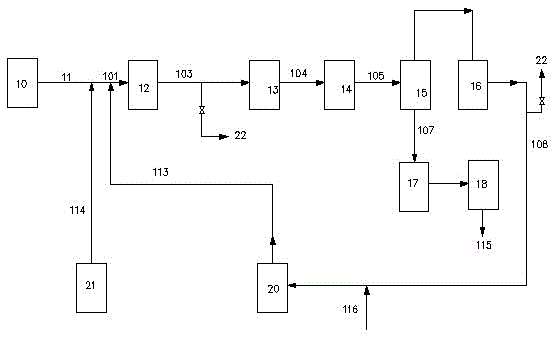

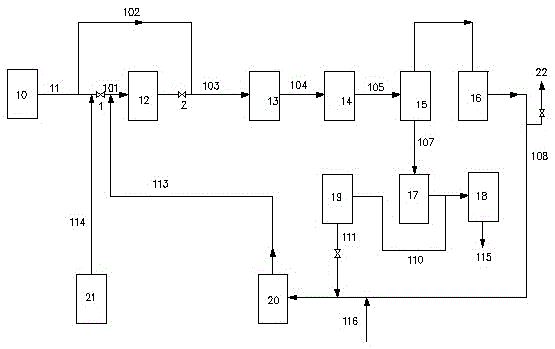

Method used

Image

Examples

Embodiment 2

[0072] Embodiment 2, the technological process of present embodiment and embodiment 1 is exactly the same, and difference is that process parameter is different, and details are as follows:

[0073] 1) Heating process:

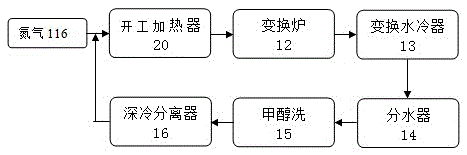

[0074] a) Nitrogen gas 116 delivered from the outside at a pressure of 3.0 MPa is heated by the start-up heater 20 and then sent to the shift furnace 12 to heat up the sulfur-resistant catalyst in the shift furnace 12, and the shift gas generated after the temperature rise enters the shift water cooler 13 After the temperature drops to 30-45°C, it enters the water separator 14, and the mixed gas 105 separated from the condensed liquid by the water separator 14 enters the methanol wash 15 for acid gas separation, and then the cryogenic separator 16 separates the It is sent to the start-up heater 20 for recycling, and after the temperature of the catalyst bed in the shift furnace 12 reaches 220° C., the delivery of nitrogen is stopped;

[0075] b) Close the val...

Embodiment 3

[0097] Embodiment 3, the technological process of present embodiment and embodiment 1 and embodiment 2 is identical, and difference is that process parameter is different, and details are as follows:

[0098] 1) Heating process:

[0099] a) Nitrogen gas 116 delivered from the outside at a pressure of 3.0 MPa is heated by the start-up heater 20 and then sent to the shift furnace 12 to heat up the sulfur-resistant catalyst in the shift furnace 12, and the shift gas generated after the temperature rise enters the shift water cooler 13 After the temperature drops to 30-45°C, it enters the water separator 14, and the mixed gas 105 separated from the condensed liquid by the water separator 14 enters the methanol wash 15 for acid gas separation, and then the cryogenic separator 16 separates the It is sent to the start-up heater 20 for recycling, and after the temperature of the catalyst bed in the shift furnace 12 reaches 220° C., the delivery of nitrogen is stopped;

[0100] b) Clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com