New application of carbide slag in sewage treatment

A technology for sewage treatment and calcium carbide slag, which is applied in the fields of water/sludge/sewage treatment, sludge treatment, processing wastewater treatment, etc. It can solve the problems of high sludge water content and high sludge treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

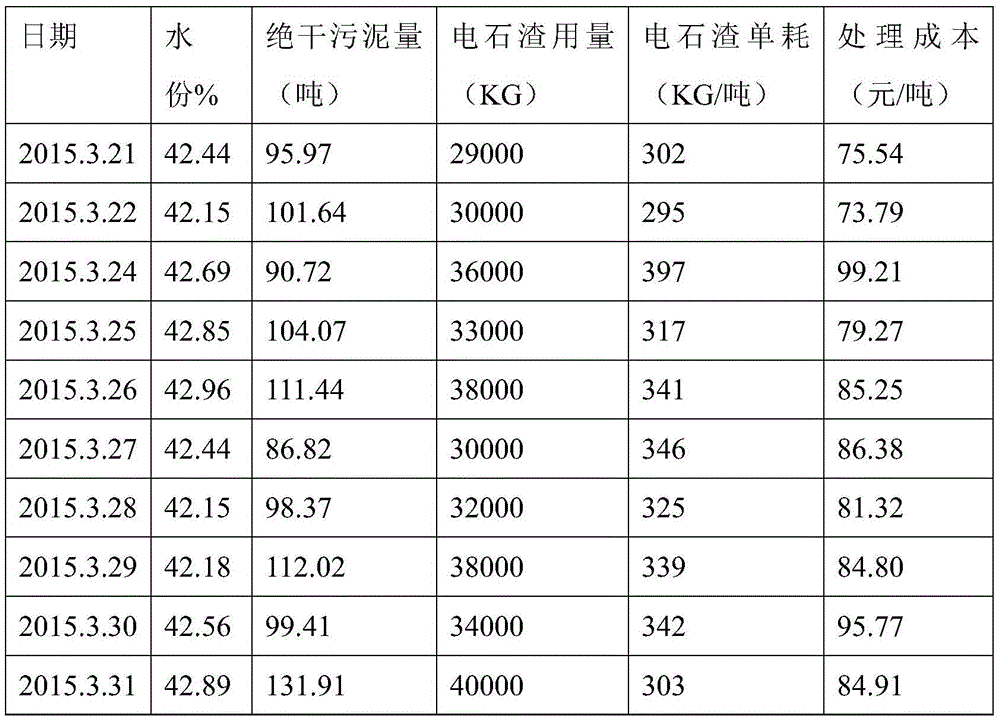

Image

Examples

Embodiment 1

[0013] Carbide slag is used for the sedimentation of biochemical sludge in pulp and papermaking sewage, according to the following steps:

[0014] Carbide slag (about 85% of calcium hydroxide in terms of mass percentage, about 3% of silicon oxide, about 1% of aluminum oxide, 2% of calcium carbonate, 2.6% of ferric oxide, 1.4% of magnesium oxide, titanium dioxide 1%, carbon slag 0.5%, calcium sulfide 0.5%, water 3%, taking the total mass of calcium carbide slag as 100%) to be added to the concentrated biochemical sludge in papermaking sewage treatment for sedimentation, and the dry matter of calcium carbide slag The mass ratio of biochemical sludge to papermaking sewage is 0.3:1. After separating the water, it enters the plate and frame sludge dewatering filter press for pressure filtration. The water content of the sludge obtained after pressure filtration is about 40%. The final sludge is sent to the boiler for incineration treatment, and part of the sulfur dioxide in the boi...

Embodiment 2

[0016] Carbide slag is used for the settlement of biochemical sludge in domestic sewage. At present, the treatment of biochemical sludge in domestic sewage treatment plants is to add flocculant for sedimentation and then send it to vacuum filter press for suction filtration. The water content of the filter residue is generally 80%-90%. If instead of adding calcium carbide slag to the sludge, using a plate and frame filter press, the water content can reach about 40%, and the implementation is carried out according to the following steps:

[0017] Calcium carbide slag (about 80% of calcium hydroxide in terms of mass percentage, about 5% of silicon oxide, about 3% of aluminum oxide, 1% of calcium carbonate, 0.6% of ferric oxide, 1% of magnesium oxide, titanium dioxide 1%, carbon slag 2.5%, calcium sulfide 0.4%, water 5%, based on the total mass of calcium carbide slag as 100%) added to the sand settling, primary settling and biochemical sludge discharged from the biological turnt...

Embodiment 3

[0019] Carbide slag is used for the sedimentation of biochemical sludge in pulp and papermaking sewage, according to the following steps:

[0020] Calcium carbide slag (calcium hydroxide 90% in terms of mass percentage, about 2% of silicon oxide, about 0.1% of aluminum oxide, and 0.7% of calcium carbonate, 0.6% of ferric oxide, 0.4% of magnesium oxide, 0.3% of titanium dioxide %, carbon slag 0.9%, calcium sulfide 0.5%, water 4.5%, taking the total mass of calcium carbide slag as 100% meter) in the concentrated biochemical sludge in the papermaking sewage treatment to carry out settlement, described calcium carbide slag dry matter and The mass ratio of biochemical sludge to dry matter of papermaking sewage is 0.25:1. After separating the water, it enters the plate and frame sludge dewatering filter press for pressure filtration. The water content of the sludge obtained after pressure filtration is about 40%. The sludge is dried and coal incinerated, and the amount of sulfur dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com