Method for preparing phenolic compound through bagasse lignin

A technology of phenolic compounds and lignin, which is applied in the field of high-efficiency catalytic conversion of lignin and resource utilization, can solve the problems of low lignin utilization efficiency, emission or burning of the environment, and avoid environmental pollution and resource waste, improve Effect of high-value utilization and high catalytic conversion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 6.9304gLa(NO 3 ) 3 ·6H 2 O, 0.8492gSr(NO 3 ) 2 , 8.0827gFe(NO 3 ) 3 9H 2 O. Dissolve in 300mL distilled water in turn, add a certain amount of NH 3 ·H 2 O adjust the pH of the solution to 10, add 0.06g cetyltrimethylammonium bromide, transfer the solution to a 500mL polytetrafluoroethylene-lined reactor, place the kettle to crystallize in an oven, and the crystallization temperature is The crystallization time at 180°C is 18hr. After the sample was cooled to room temperature, it was transferred to a beaker, and the upper liquid was transferred to a centrifuge tube for centrifugation at a speed of 8000r / min for 5 minutes, washed with distilled water for 3 times, dried at 120°C for 8hrs, and roasted at 800°C for 5hrs to obtain La 0.8 Sr 0.2 FeO 3 solid.

[0023] Weigh 2.5g bagasse lignin and 2.5gLa 0.8 Sr 0.2 FeO 3 After fully mixing, use a powder tablet press to compress the tablets at a pressure of 20 MPa for 10 minutes to obtain a tablet mixture, w...

Embodiment 2

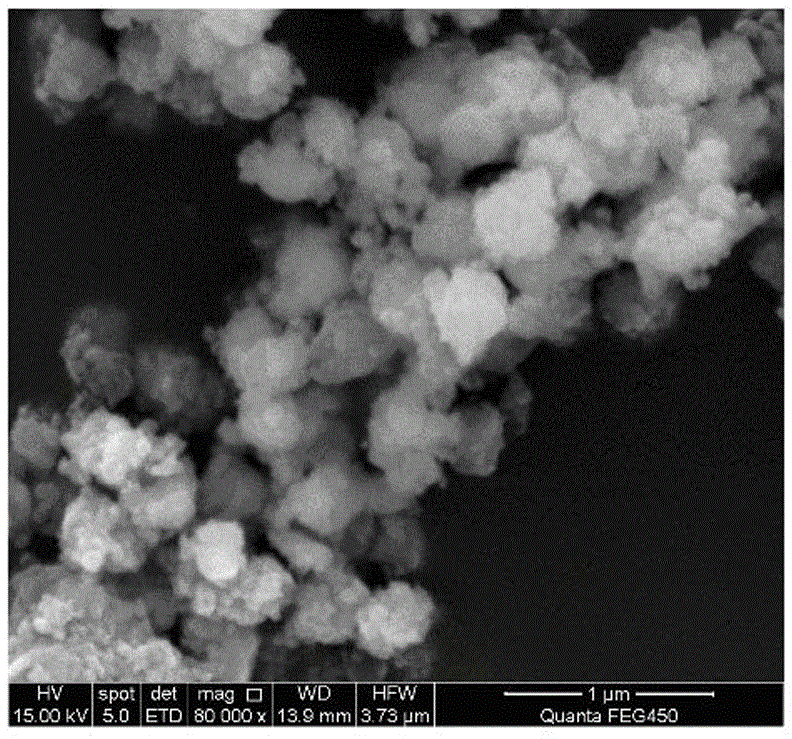

[0026] Weigh 4.7230gCa(NO 3 ) 2 ·6H 2 O, 6.8691gZr(NO 3 ) 4 ·5H 2 O, 1.6160gFe(NO 3 ) 3 9H 2 O was dissolved in 300mL distilled water in turn, and a certain amount of NH 3 ·H 2 O adjust the pH of the solution to 10.5, add 0.03g cetyltrimethylammonium bromide, transfer the solution to a 500mL polytetrafluoroethylene-lined reaction kettle, place the still in an oven for crystallization, and the crystallization temperature is The crystallization time at 180°C is 18hr. After the sample is cooled to room temperature, it is transferred to a beaker, and the upper layer liquid is transferred to a centrifuge tube for centrifugation at a speed of 6000r / min for 8 minutes, washed 3 times with distilled water, dried at 120°C for 8hrs, and roasted at 800°C for 5hrs to obtain CaZr 0.8 Fe 0.2 o 3 Solid, its scanning electron microscope picture is as follows figure 1 .

[0027] Weigh 2.5g bagasse lignin and 2.5gCaZr 0.8 Fe 0.2 o 3 After fully mixing, use a powder tablet press ...

Embodiment 3

[0030] Weigh 4.3300gLa(NO 3 ) 3 ·6H 2 O, 2.1163gSr(NO 3 ) 2 , 8.0800gFe(NO 3 ) 3 9H 2 O was dissolved in 300mL distilled water in turn, and a certain amount of NH 3 ·H 2 O adjust the pH of the solution to 8, add 0.09g cetyltrimethylammonium bromide, transfer the solution to the reaction kettle of the 500mL polytetrafluoroethylene liner, place the still in an oven for crystallization, and the crystallization temperature is The crystallization time at 250°C is 12hr. After the sample was cooled to room temperature, it was transferred to a beaker, and the upper liquid was transferred to a centrifuge tube for centrifugation at a speed of 12000r / min for 5min, washed with distilled water for 3 times, dried at 120°C for 8hr, and roasted at 800°C for 6hr to obtain La 0.5 Sr 0.5 FeO 3 solid.

[0031] Weigh 0.4g bagasse lignin and 4.0gLa 0.5 Sr 0.5 FeO 3 After fully mixing, use a powder tablet press to compress tablets at a pressure of 10 MPa for 30 minutes to obtain a tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com