A kind of method for preparing magnesia aerogel with bischofite as raw material

A bischofite and magnesium oxide technology, applied in the direction of magnesium oxide, can solve the problems of high toxicity of magnesium alkoxide, difficult process control, temperature and humidity sensitivity, etc., and achieve large raw material reserves, difficult synthesis, and good formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix bischofite, distilled water, ethanol, and polyvinyl alcohol, stir for 20 minutes to obtain a transparent solution, then add propylene oxide to the solution and stir for 10 minutes to obtain a sol; The mass ratio of oxypropane is 1:10:10:0.05:2.

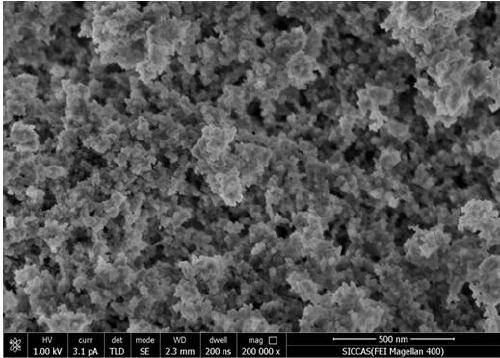

[0040]Seal the above sol for gelation, the gelation temperature is 30°C, and the gelation time is 2h to obtain a magnesium oxide wet gel, then soak and wash it with distilled water three times, each time for 2h, and finally in the normal pressure environment of 80°C Dry for 24 h to obtain MgO airgel. The density of the above magnesium oxide airgel is 0.15 g cm -3 , porosity 95.0%, BET specific surface area 200m 2 g -1 , the pore size distribution is 5~250nm, the compressive modulus is 1.7 MPa, and the thermal conductivity is 0.03 W m -1 k -1 .

Embodiment 2

[0042] Mix bischofite, distilled water, ethanol, and polymaleic anhydride, stir for 30 minutes to obtain a transparent solution, then add propylene oxide to the solution and stir for 5 minutes to obtain a sol; wherein bischofite, distilled water, ethanol, polymaleic anhydride The mass ratio of acid anhydride to propylene oxide is 1:1:5:0.05:4.

[0043] Seal the above sol for gelation, the gelation temperature is 70°C, and the gelation time is 20h to obtain a magnesium oxide wet gel, then soak and wash it with distilled water for four times, each time for 3h, and finally under the normal pressure of 80°C After drying for 24 h under ambient conditions, magnesium oxide airgel was obtained. The density of the above magnesium oxide airgel is 0.85 g cm -3 , the porosity is 71.6%, and the BET specific surface area is 50m 2 g -1 , the pore size distribution is 10~200nm, the compressive modulus is 30 MPa, and the thermal conductivity is 0.10W m -1 k -1 .

Embodiment 3

[0045] Mix bischofite, distilled water, isopropanol, and polymaleic anhydride, stir for 120 minutes to obtain a transparent solution, then add epichlorohydrin to the solution and stir for 60 minutes to obtain a sol; wherein bischofite, distilled water, isopropyl The mass ratio of alcohol, polymaleic anhydride and epichlorohydrin is 1:10:20:0.05:5.

[0046] Seal the above sol for gelation, the gelation temperature is 60°C, and the gelation time is 10h to obtain a magnesium oxide wet gel, then soak and wash with distilled water four times, each time for 3h, and finally vacuum freeze at -80°C After drying for 24 h, magnesium oxide airgel was obtained. The density of the above magnesium oxide airgel is 0.11 g cm -3 , porosity 96.3%, BET specific surface area 520m 2 g -1 , the pore size distribution is 5~210nm, the compressive modulus is 1.2 MPa, and the thermal conductivity is 0.027W m -1 k -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com