Preparation and Application of Palladium Catalyst Supported on Oyster Shells from Marine Biowaste

A technology of palladium catalyst and oyster shell is applied in the preparation of organic compounds, physical/chemical process catalysts, preparation of carboxylic acid amides, etc., can solve problems such as high price of homogeneous palladium catalyst, environmental pollution, etc., achieves wide range of materials and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

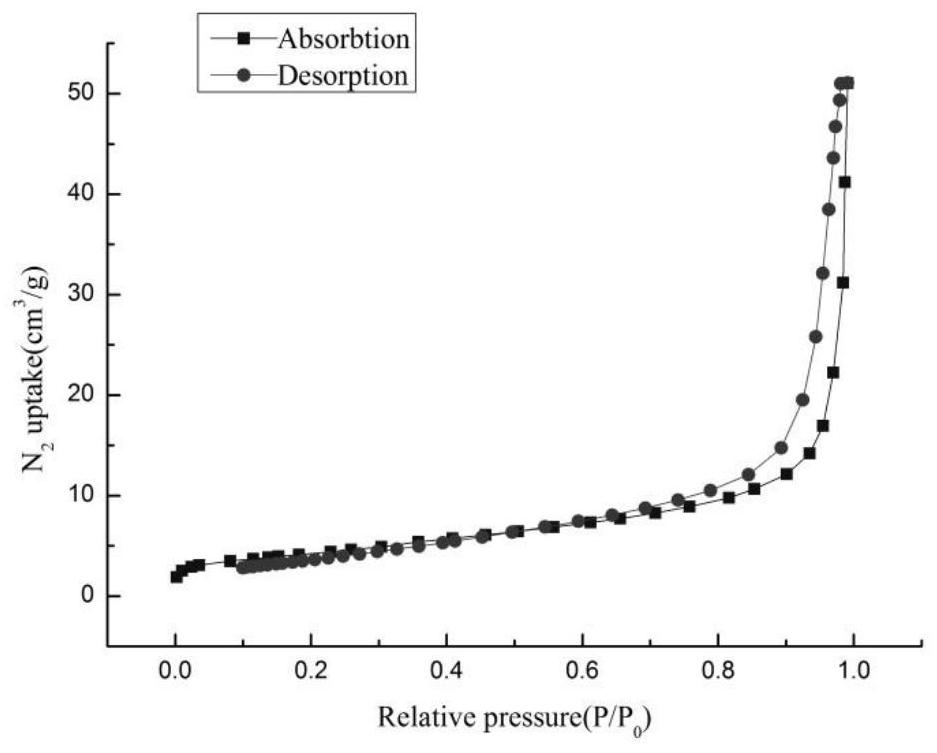

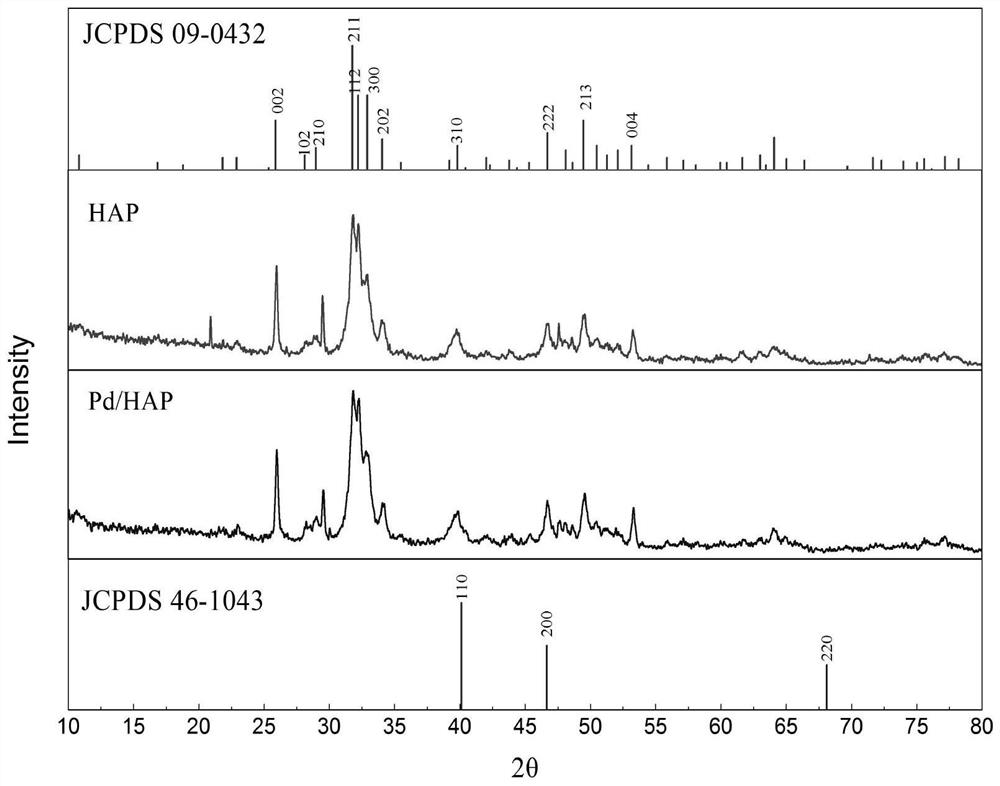

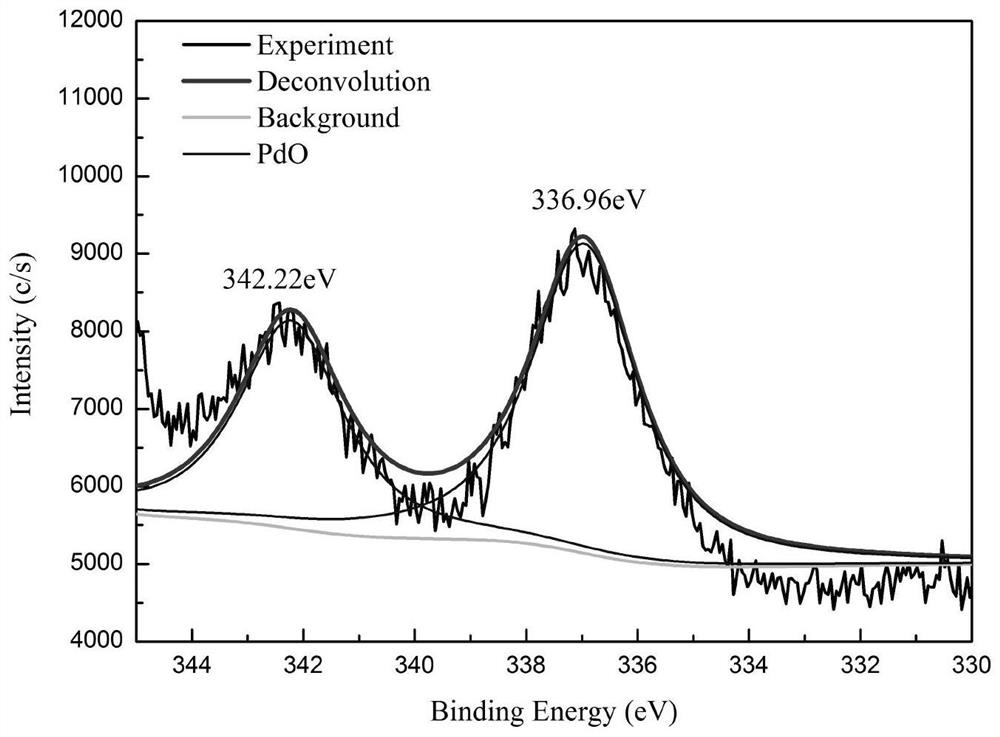

[0047] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0048] (1) Fresh oyster shells are cleaned and air-dried naturally, add an appropriate amount of 10% sodium hydroxide solution, and heat at 95°C for 5 hours to fully remove protein;

[0049] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0050] (3) Take oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide and add them to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 5:6) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0051] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deion...

Embodiment 2

[0066] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0067] (1) Fresh oyster shells are cleaned and air-dried naturally, soaked in 5% sodium hypochlorite solution for 1 day to remove protein;

[0068] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0069] (3) Add oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 1:1) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0070] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deionized water for 3 to 6 times until no carbonate ion is det...

Embodiment 3

[0084] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0085] (1) Fresh oyster shells are cleaned and air-dried naturally, add an appropriate amount of 10% sodium hydroxide solution, and heat at 95°C for 5 hours to fully remove protein;

[0086] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0087](3) Take oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide and add them to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 5:6) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0088] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com