Preparation method of variable color nanofiber film

A nanofiber film and color-changing technology, which is applied in fiber treatment, textiles, papermaking, non-woven fabrics, etc., can solve the problems of large performance impact, easy blockage of needles, low output, etc., and achieve simple preparation process, low cost, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

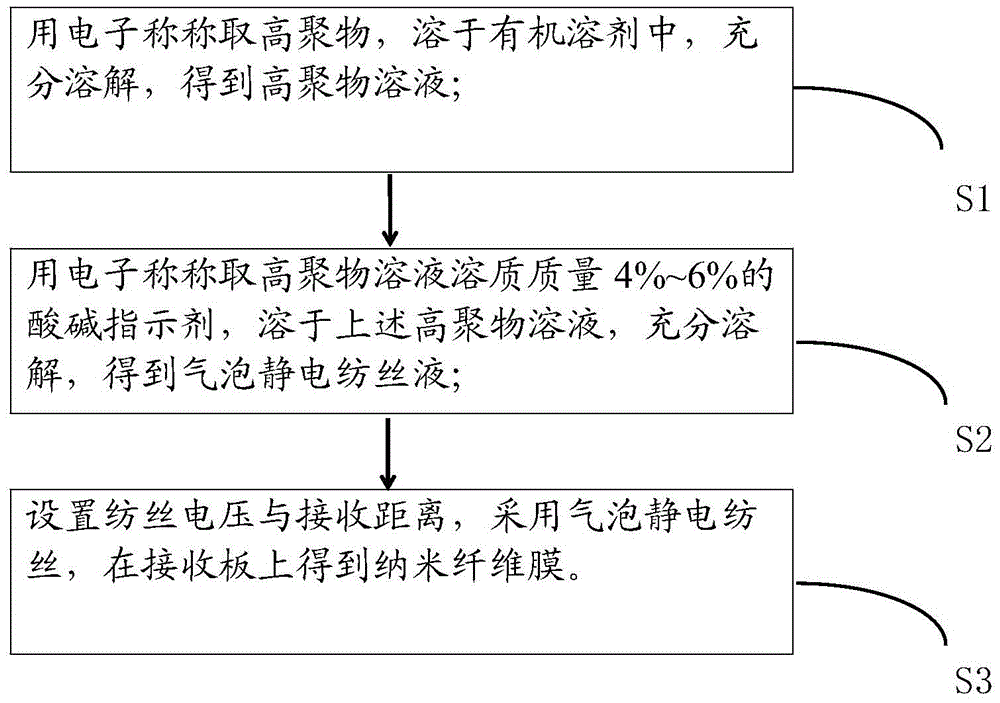

[0029] Such as figure 1 Shown, the preparation method of a kind of variable color nanofibrous film of the present invention, it comprises steps:

[0030] S1: Weigh the polymer with an electronic scale, dissolve it in an organic solvent, and fully dissolve it to obtain a polymer solution;

[0031] S2: Weigh an acid-base indicator with a solute mass of 4% to 6% of the polymer solution with an electronic scale, dissolve it in the above polymer solution, and fully dissolve it to obtain a bubble electrospinning solution;

[0032] S3: Set the appropriate spinning voltage and receiving distance, adopt air bubble electrospinning, and obtain the nanofiber film on the receiving plate.

[0033] In the step S1, the high polymer is a water-insoluble high polymer such as polyacrylonitrile, polyvinylidene fluoride, polystyrene, polyethersulfone, or polylactic acid.

[0034] In the step S1, the organic solvent is N,N-dimethylformamide or N,N-dimethylacetamide or a mixed solvent of N,N-dimet...

Embodiment 1

[0050] A method for preparing a variable color nanofibrous membrane, the steps are:

[0051] (1) Weigh 2.5g of polyacrylonitrile with an electronic scale, dissolve in 25g of N,N-dimethylformamide, and fully dissolve;

[0052] (2) Take 0.15g of phenolphthalein with an electronic scale and dissolve it in the above solution to obtain a bubble electrospinning solution;

[0053] (3) Bubble spinning: the spinning voltage is 20V, and the receiving distance is 20cm.

Embodiment 2

[0055] A method for preparing a variable color nanofibrous membrane, the steps are:

[0056] (1) Weigh 3.5g of polyvinylidene fluoride with an electronic scale, dissolve in 25g of N,N-dimethylformamide, and fully dissolve;

[0057] (2) Take 0.175g phenolphthalein with an electronic scale and dissolve it in the above solution to obtain a bubble electrospinning solution;

[0058] (3) Bubble spinning: the spinning voltage is 20V, and the receiving distance is 20cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com