A pretreatment method for the determination of graphite chemical composition content

A chemical composition and pretreatment technology, applied in the preparation of test samples, measuring devices, scientific instruments, etc., can solve problems such as splashing, element loss, and inaccurate content, and achieve high accuracy, no element loss, and complete decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

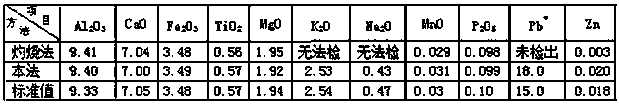

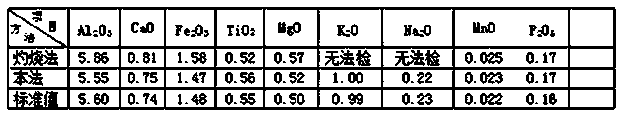

Examples

Embodiment 1

[0019] Embodiment 1, this embodiment includes the following steps: (1) Weigh 0.1g of graphite sample in the digestion tank of microwave digestion instrument, slowly add 2mL of nitric acid HNO 3 , 0.5mL of hydrofluoric acid HF, 0.5mL of sulfuric acid H 2 SO 4 , 0.5mL of perchloric acid HCLO 4 , gently shake the digestion tank to fully mix the graphite sample with each acid reagent;

[0020] (2) Put the digestion tank on the microwave digestion instrument, and the microwave digestion instrument starts to run and heat up at a power of 600W. When the temperature rises to 240°C, keep the time for not less than 45 minutes, and the microwave digestion instrument stops working. When the temperature is below 70°C, take out the digestion tank from the microwave digestion instrument, slowly open the digestion tank, pour it into a polytetrafluoroethylene beaker, and use a 100mL plastic colorimetric tube to make up the volume.

Embodiment 2

[0021] Embodiment 2, this embodiment comprises the following steps: (1) Weigh 0.5g graphite sample in the digestion tank of microwave digestion instrument, slowly add 3mL of nitric acid HNO 3 , 0.4mL of hydrofluoric acid HF, 0.8mL of sulfuric acid H 2 SO 4 , 0.3mL of perchloric acid HCLO 4 , gently shake the digestion tank to fully mix the graphite sample with each acid reagent;

[0022] (2) Place the digestion tank on the microwave digestion instrument, and the microwave digestion instrument starts to run and heat up at a power of 600W. When the temperature rises to 250°C, keep the time for not less than 45 minutes, and the microwave digestion instrument stops working, and naturally cools down. When the temperature is below 70°C, take out the digestion tank from the microwave digestion instrument, slowly open the digestion tank, pour it into a polytetrafluoroethylene beaker, and use a 100mL plastic colorimetric tube to make up the volume.

Embodiment 3

[0023] Embodiment 3, this embodiment comprises the following steps: (1) Weigh 0.4g graphite sample in the digestion jar of microwave digestion apparatus, slowly add the nitric acid HNO of 2.5mL successively 3 , 0.2mL of hydrofluoric acid HF, 0.5mL of sulfuric acid H 2 SO 4 , 0.2mL of perchloric acid HCLO 4 , gently shake the digestion tank to fully mix the graphite sample with each acid reagent;

[0024] (2) Put the digestion tank on the microwave digestion instrument. The microwave digestion instrument starts to run and heat up at a power of 600W. When the temperature rises to 260°C, keep it for no less than 45 minutes. The microwave digestion instrument stops working and naturally cools down. When the temperature drops When the temperature is below 70°C, take out the digestion tank from the microwave digestion instrument, slowly open the digestion tank, pour it into a polytetrafluoroethylene beaker, and use a 100mL plastic colorimetric tube to make up the volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com