Methanol gas sensor and preparation method thereof

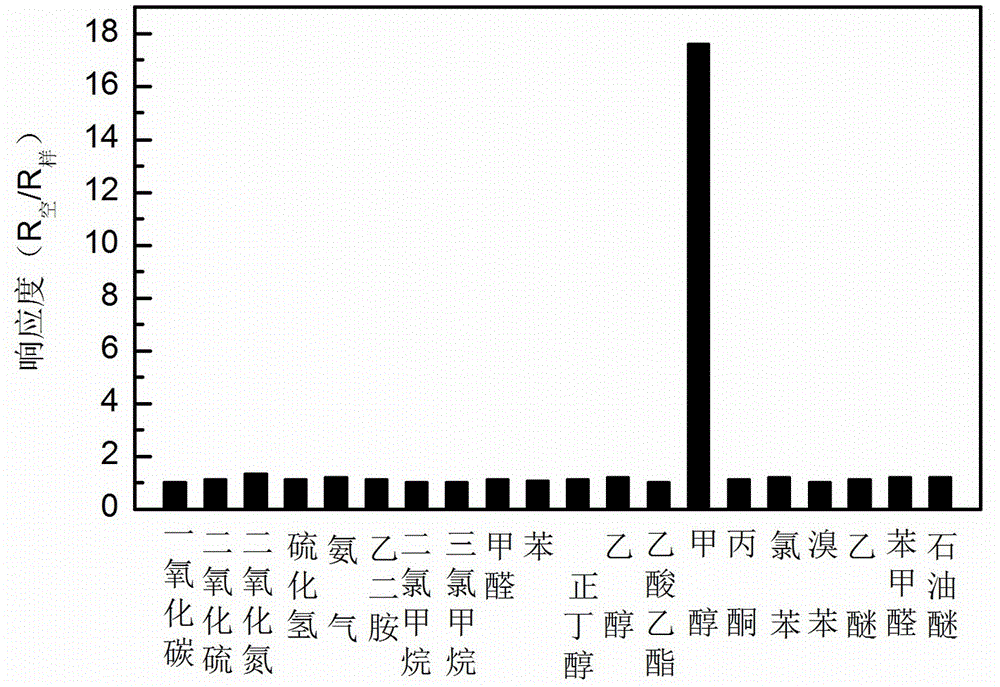

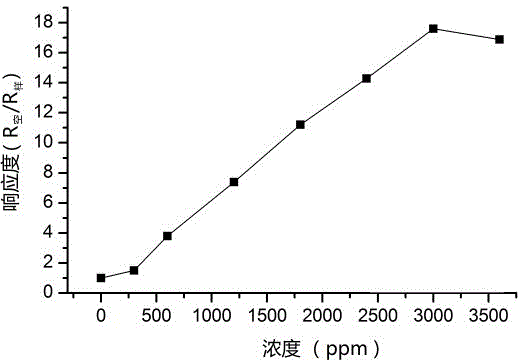

A gas sensor and sensor technology, applied in the field of sensors, to achieve the effects of no sintering, good selectivity and high responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Take 100 parts by weight of Sn (bipyO 2 ) 2 Cl 2 The solid was ground for 3 hours, and then uniformly dispersed in deionized water under 30kHz ultrasonic waves; another 0.1 part by weight of graphene oxide was uniformly dispersed in deionized water under 30kHz ultrasonic waves, and then slowly added to Sn under ultrasonic waves. (bipyO 2 ) 2 Cl 2 In the dispersion liquid, evaporate 80%, then add 0.1% polyvinyl alcohol to obtain a sol.

[0022] 2) Take the aluminum oxide ceramic circular substrate, put it into a sodium hydroxide solution with a concentration of 6 mol / liter and boil for 30 minutes, take it out after cooling, rinse it three times with distilled water, and dry it in an oven. Au slurry was coated on the cleaned Al2O3 ceramic substrate to make interdigitated electrodes, dried, and then Pt wires with a diameter of 0.1 mm were welded to the electrodes as lead wires.

[0023] 3) The graphene prepared in step 1) was doped with Sn (bipyO 2 ) 2 Cl 2 The...

Embodiment 2

[0025] 1) Take 100 parts by weight of Sn (bipyO 2 ) 2 Cl 2 The solid was ground for 3 hours, and then uniformly dispersed in deionized water under 40kHz ultrasonic waves; another 0.5 weight of graphene oxide was uniformly dispersed in deionized water under 40kHz ultrasonic waves, and then slowly added to Sn under ultrasonic waves. (bipyO 2 ) 2 Cl 2 In the dispersion liquid, evaporate two-thirds of the water, and then add 0.1% polyvinyl alcohol to obtain a sol.

[0026] 2) Take the aluminum oxide ceramic circular substrate, put it into a sodium hydroxide solution with a concentration of 6 mol / liter and boil for 30 minutes, take it out after cooling, rinse it three times with distilled water, and dry it in an oven. Au slurry was coated on the cleaned Al2O3 ceramic substrate to make interdigitated electrodes, dried, and then Pt wires with a diameter of 0.1 mm were welded to the electrodes as lead wires.

[0027] 3) The graphene prepared in step 1) was doped with Sn (bipyO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com