Silica-based gallium nitride growing method based on graphene and magnetron sputtering aluminum nitride

A magnetron sputtering and growth method technology, applied in the field of electronics, can solve the problems of difficult growth, high substrate cost, poor crystal quality, etc., and achieve the effect of overcoming difficulties in nucleation, high dislocation density, and easy nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

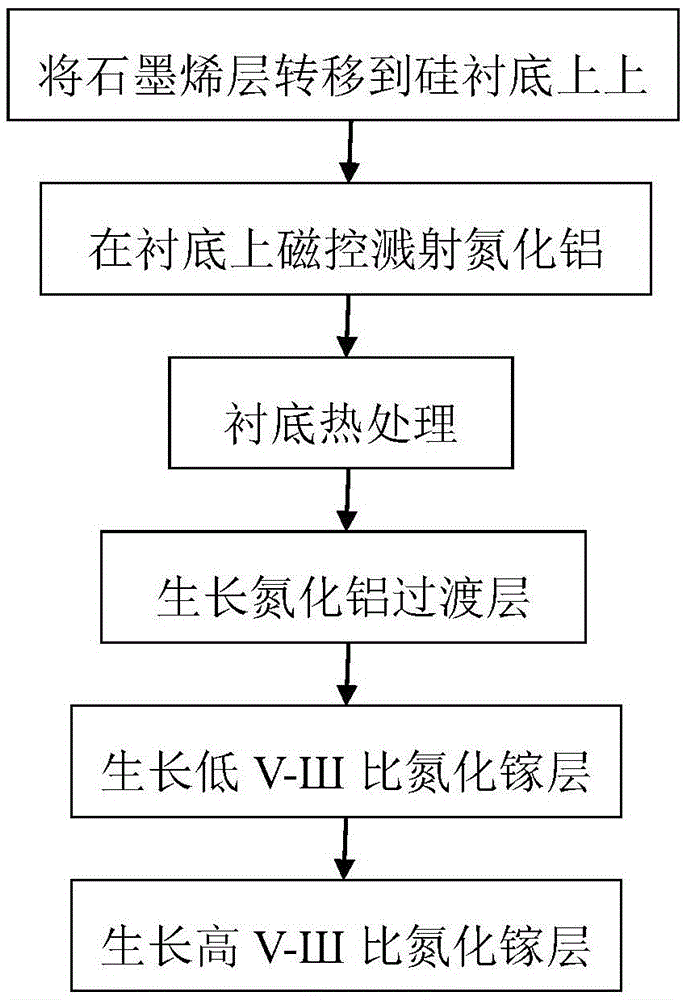

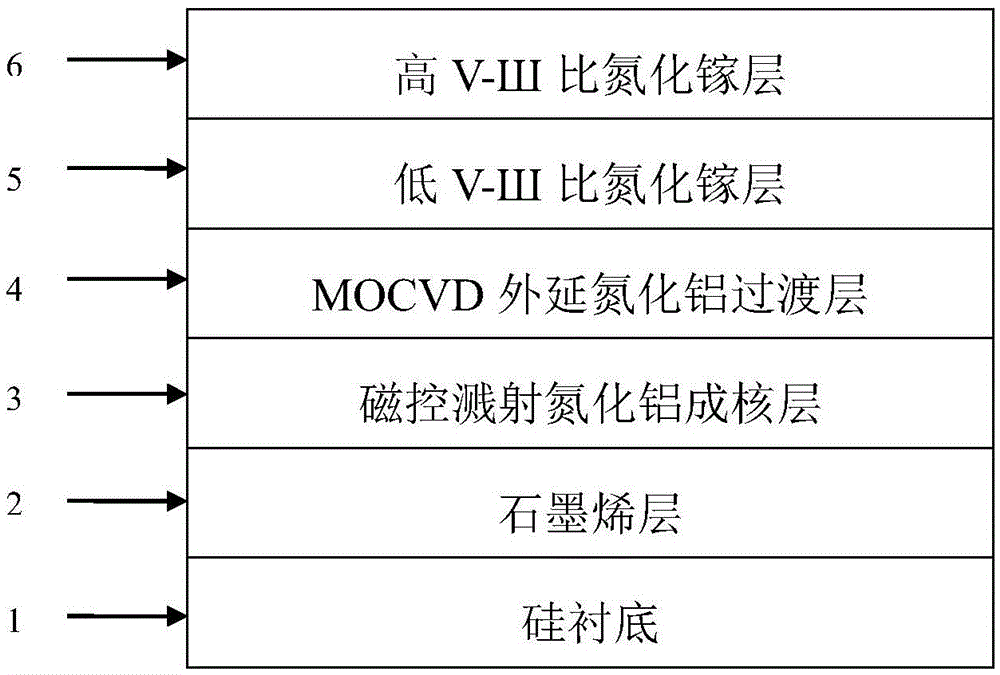

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Growth of gallium nitride on a silicon (100) substrate based on graphene and magnetron sputtering aluminum nitride.

[0053] Step 1: Transfer graphene.

[0054] Adopt chemical vapor deposition method, grow the single-layer graphene of 0.34nm on the copper substrate, then place the single-layer graphene in the mixed solution of 1M ferric chloride and 2M hydrochloric acid for 12 hours, remove the metal substrate after finally The single-layer graphene is transferred onto a silicon (100) substrate to obtain a silicon (100) substrate covered with graphene with a thickness of 0.34 nm.

[0055] Step 2: magnetron sputtering aluminum nitride.

[0056] The silicon (100) substrate covered with graphene is placed in a magnetron sputtering system, the pressure of the reaction chamber is 1Pa, nitrogen and argon are introduced into the system for 5 minutes, and aluminum with a purity of 5N is used as the target material, and radio frequency magnetron sputtering is adopted...

Embodiment 2

[0065] Example 2: Growth of gallium nitride on a silicon (111) substrate based on graphene and magnetron sputtering aluminum nitride.

[0066] Step A: Transfer graphene.

[0067] Adopt chemical vapor deposition method, grow the single-layer graphene of 0.34nm on the copper substrate, then place the single-layer graphene in the mixed solution of 1M ferric chloride and 2M hydrochloric acid for 12 hours, remove the metal substrate after finally The single-layer graphene was transferred to a silicon (111) substrate to obtain a silicon (111) substrate covered with graphene with a thickness of 0.34 nm.

[0068] Step B: magnetron sputtering aluminum nitride.

[0069] The silicon (111) substrate covered with graphene is placed in a magnetron sputtering system, the pressure of the reaction chamber is 1Pa, nitrogen and argon are introduced into the system for 5 minutes, and aluminum with a purity of 5N is used as the target material, and radio frequency magnetron sputtering is adopted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com