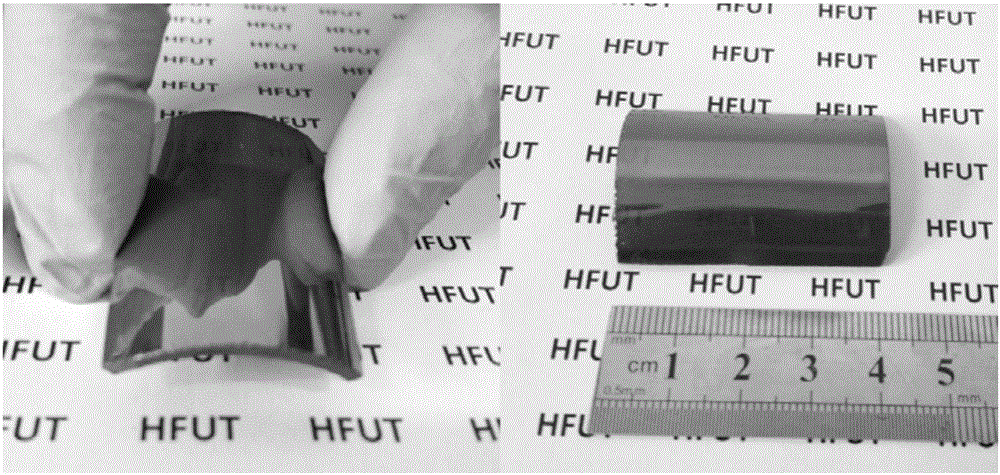

A large-area preparation method for perovskite thin films suitable for various substrate shapes

A perovskite and thin film technology, which is applied in the field of large-area preparation of perovskite thin films, can solve the problems of restricting the large-scale preparation of perovskite thin films, restricting the development and application of flexible perovskite photovoltaic devices, and difficult spin-coating operations. The effect of avoiding expensive vacuum evaporation equipment investment, low-cost high-quality preparation, and avoiding glove box operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a perovskite light-absorbing layer film is prepared with a curved rigid glass as a substrate, and the specific steps are as follows:

[0029] a. Use soapy water, acetone, and ethanol to ultrasonically clean the curved glass substrate for 20 minutes, then dry it with nitrogen wind, and set aside;

[0030] b. In a 250mL beaker, add 20mL of Pb(NO 3 ) 2 solution, 10mL of 1.5M thiourea solution, 26mL of 26% ammonia water and 144mL of deionized water were added, and then stirred at room temperature for 5 minutes at a speed of 1000rpm to obtain a lead sulfide reaction solution.

[0031] c. Put the cleaned substrate into the lead sulfide reaction solution, then put the beaker in a water bath at 70°C, and react for 30 minutes; after the reaction in the chemical bath, take out the substrate and rinse the surface of the sample with deionized water, Dry the sample with nitrogen wind to obtain a high-quality PbS precursor film;

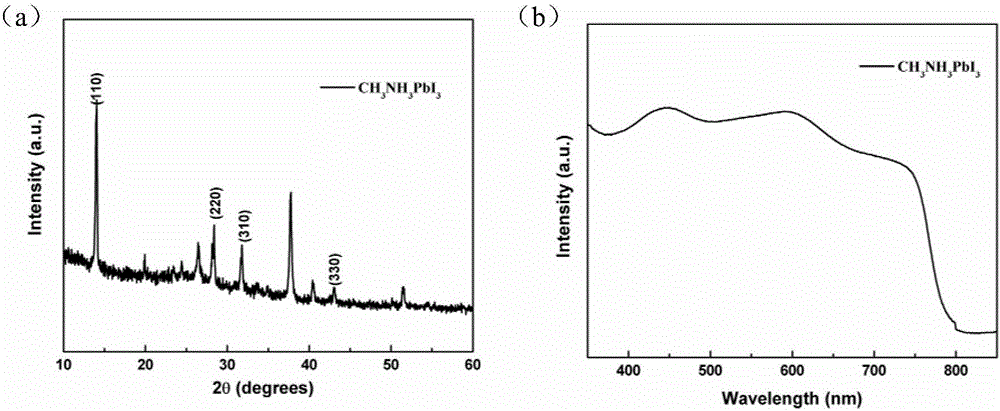

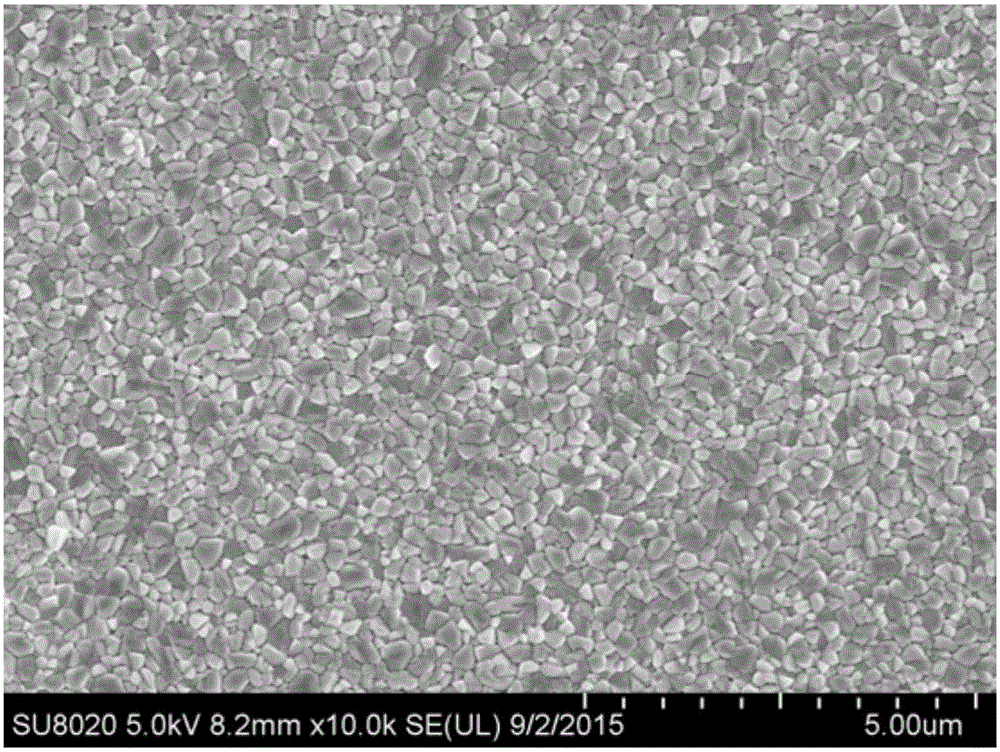

[0032] d. Combine PbS film wit...

Embodiment 2

[0038] In this embodiment, the perovskite light absorbing layer CH is prepared in the same manner as in Example 1. 3 NH 3 PB 3 thin film, the only difference is that the temperature of the heating stage in step d is 180°C, and the reaction time is 30 minutes.

[0039] After characterization, the CH prepared in this example 3 NH 3 PB 3 The film is similar to Example 1, the surface is uniform and smooth, and the film quality is high.

Embodiment 3

[0041] In this embodiment, the perovskite light absorbing layer CH is prepared in the same manner as in Example 1. 3 NH 3 PB 3 thin film, the only difference is that step d is carried out as follows:

[0042] Put the PbS film as the reactant, place it on a heating platform, put 2g of iodine beside it, cover it with a black cover, heat to 100°C, and react for 60 minutes to obtain PbI 2 film;

[0043] PbI 2 The film was immersed in CH at a concentration of 10 mg / mL 3 NH 3 I in isopropanol solution, the soaking time is 2 minutes, the soaking temperature is 25 ℃, after the reaction is completed, take it out and dry it to get CH 3 NH 3 PB 3 film.

[0044] After characterization, the CH prepared in this example 3 NH 3 PB 3 The film is similar to Example 1, the surface is uniform and smooth, and the film quality is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com