Method for treating paint-spraying volatile organic waste gas in coating workshop

A volatile organic and waste gas technology, used in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of large fluctuation of waste gas sources, difficult microbes to form films, and low treatment efficiency, and achieve easy loading and biological efficiency. The effect of film hanging, low resistance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

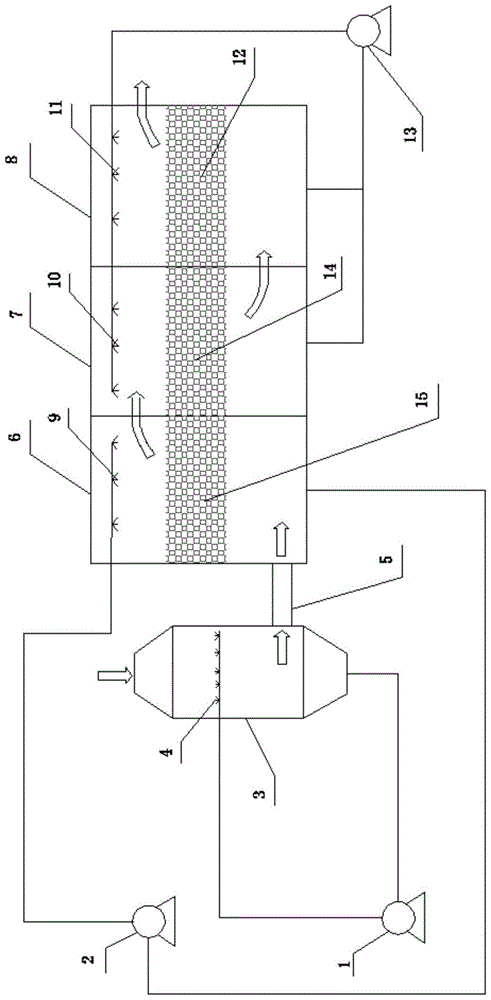

Method used

Image

Examples

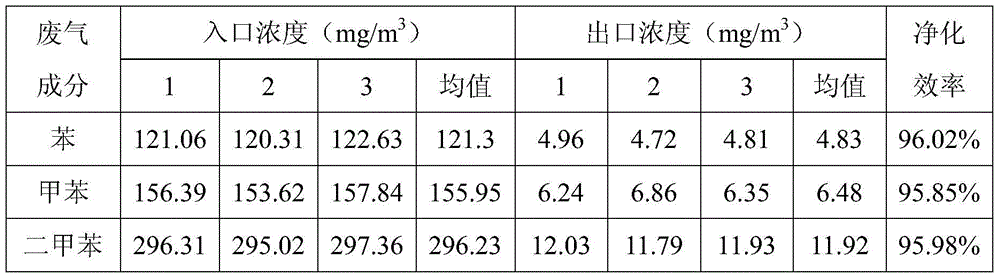

Embodiment 1

[0029] 1. Preparation of absorbing tower spray liquid: ethyl acetate: ethanol: water=5%: 5%: 90% (mass ratio);

[0030] 2. Take the activated sludge produced in the biochemical treatment process of the sewage treatment plant; mix the activated sludge: sodium acetate: urea: phosphate: toluene according to the mass ratio of 1000:100:6~12:2~4:2~ 4 (wherein phosphate is potassium dihydrogen phosphate: the mixture of dipotassium hydrogen phosphate=4:1 (mass ratio)) obtains the treated first-stage activated sludge; 1m 3 Add 8kg of activated sludge with a moisture content of 92% to the alumina foam ceramic filter and place it for 3 days. The alumina foam ceramic filter can be purchased from Jincheng Fuji New Material Co., Ltd. The layer height of the device is 0.5m, and the aperture ppi is 10-40;

[0031] 3. Dilute the treated first-stage activated sludge with water to a moisture content of 99%, place it on the loaded alumina ceramic foam filter, add an appropriate amount of water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com