Natural fiber environment-friendly adsorption material and method for preparing same

A technology of adsorbing materials and natural fibers, applied in the field of materials, can solve the problems of human health and plant survival hazards, and achieve the effect of strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

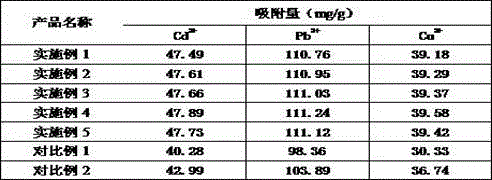

Examples

Embodiment 1

[0022] A natural fiber environmental protection adsorption material, prepared from the following ingredients in parts by weight: 10 parts of carboxymethyl cellulose, 10 parts of carboxymethyl hydroxyethyl cellulose, 5 parts of carboxymethyl hydroxypropyl cellulose, cellulose 5 parts of sodium sulfate, 5 parts of glyoxylic acid, 2 parts of sodium alginate, 0.5 parts of palm wax, 1 part of phosphatidylinositol, 1 part of starch sugar alcohol, 0.1 part of carnosol, 0.1 part of ethylene oxide, 0.1 part of squalane, 1 part of chitosan, 1 part of sodium hydroxide, 60 parts of water.

[0023] The preparation method of the above-mentioned natural fiber environmental protection adsorption material is: first mix carboxymethyl cellulose, carboxymethyl hydroxyethyl cellulose, carboxymethyl hydroxypropyl cellulose, cellulose sodium sulfate, sodium alginate and 60 parts of water , stirred slowly with a glass rod for 10 minutes, then stirred with a magnetic stirrer at a speed of 80r / min for ...

Embodiment 2

[0025] A natural fiber environmental protection adsorption material, prepared by weight parts from the following ingredients: 14 parts of carboxymethyl cellulose, 12 parts of carboxymethyl hydroxyethyl cellulose, 6 parts of carboxymethyl hydroxypropyl cellulose, cellulose 6-9 parts of sodium sulfate, 6 parts of glyoxylic acid, 3 parts of sodium alginate, 0.6 parts of palm wax, 1.1 parts of phosphatidylinositol, 1.2 parts of starch sugar alcohol, 0.12 parts of carnosol, 0.12 parts of ethylene oxide , 0.11 parts of squalane, 1.2 parts of chitosan, 1.3 parts of sodium hydroxide, and 65 parts of water.

[0026] The preparation method of the above-mentioned natural fiber environmental protection adsorption material is: first mix carboxymethyl cellulose, carboxymethyl hydroxyethyl cellulose, carboxymethyl hydroxypropyl cellulose, cellulose sodium sulfate, sodium alginate and 60 parts of water , stirred slowly with a glass rod for 12 minutes, then stirred with a magnetic stirrer at a...

Embodiment 3

[0028] A kind of natural fiber environmental protection adsorption material, is prepared from the following ingredients in parts by weight: 15 parts of carboxymethyl cellulose, 15 parts of carboxymethyl hydroxyethyl cellulose, 7.5 parts of carboxymethyl hydroxypropyl cellulose, cellulose 7.5 parts of sodium sulfate, 7.5 parts of glyoxylic acid, 3.5 parts of sodium alginate, 0.7 parts of palm wax, 1.5 parts of phosphatidylinositol, 1.5 parts of starch sugar alcohol, 0.15 parts of carnosol, 0.15 parts of ethylene oxide, 0.15 parts of squalane, 1.5 parts of chitosan, 1.5 parts of sodium hydroxide, 70 parts of water.

[0029] The preparation method of above-mentioned natural fiber environmental protection adsorption material is: first carboxymethyl cellulose, carboxymethyl hydroxyethyl cellulose, carboxymethyl hydroxypropyl cellulose, cellulose sodium sulfate, sodium alginate and 65 parts of water are mixed , stirred slowly with a glass rod for 15 minutes, then stirred with a magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com