Process and device for preparing graphene tire by coproduction

A graphene and tire technology, which is applied in the field of co-production of graphene tire production technology and its device field, can solve the problems of easy puncture, poor tire quality, easy puncture, easy to be punctured, etc. Extend life and increase anti-puncture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

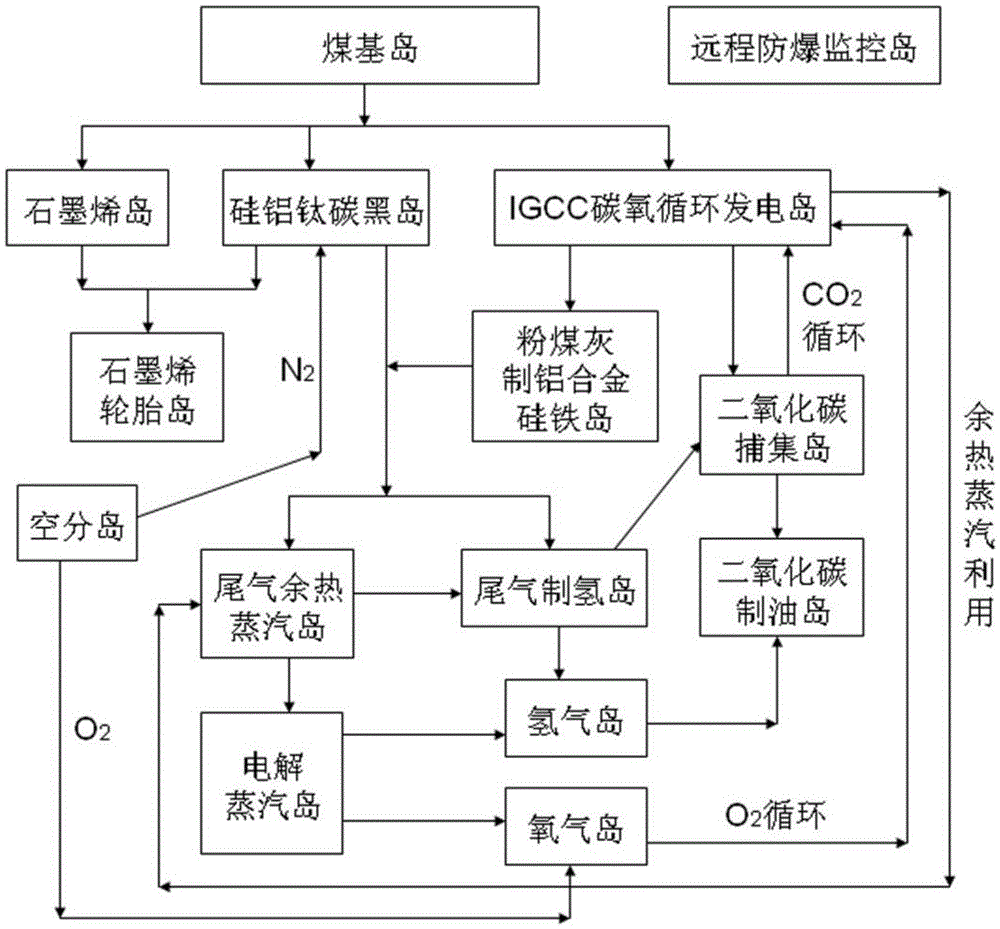

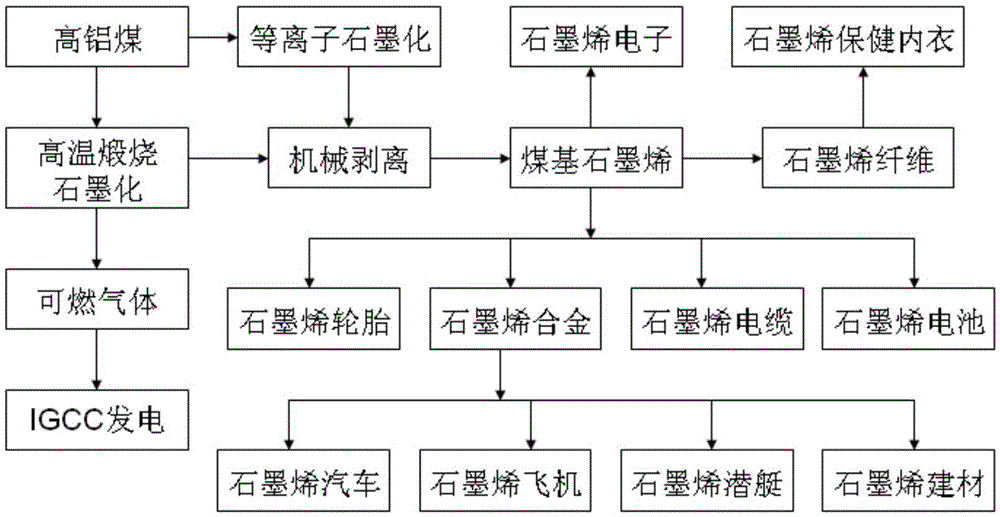

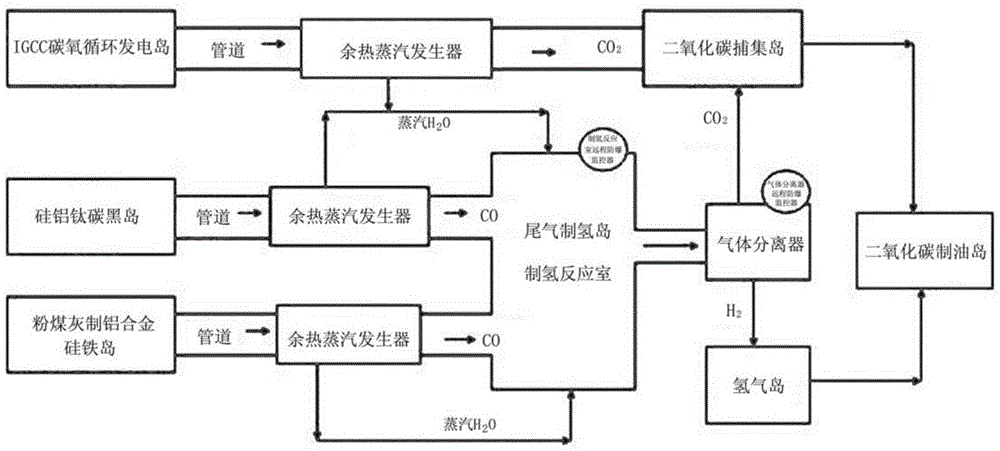

[0026] Embodiment 1: as figure 1 As shown, a device for producing graphene tires through joint production, including: coal-based islands, silicon-aluminum-titanium carbon black islands, graphene islands, graphene tire islands, IGCC carbon-oxygen cycle power generation islands, and aluminum alloys made of fly ash Ferrosilicon island, carbon dioxide capture island, tail gas waste heat steam island, tail gas hydrogen production island, air separation island, carbon dioxide oil production island, remote explosion-proof monitoring island; the coal-based island and silicon aluminum titanium carbon black island, graphene island, IGCC carbon-oxygen cycle power generation island connection, silicon aluminum titanium carbon black island, graphene island and graphene tire island connection, IGCC carbon-oxygen cycle power generation island and fly ash aluminum alloy silicon iron island, carbon dioxide capture island, exhaust waste heat steam The island is connected, the silicon aluminum t...

Embodiment 2

[0067] Embodiment 2: as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a graphene new energy vehicle island, a graphene lithium titanium rare earth battery island, a graphene bulletproof and anti-sticking film island, a graphene air purification filter membrane island, and a graphene brake island. Chip island, graphene flame-retardant fiber material island, graphene engine island, graphene intelligent control electronic component island. The coal-based island sends the coal base to the graphitization island to remove volatile matter and then sends it to the graphene island and the silicon-aluminum-titanium carbon black island to prepare graphene and silicon-aluminum-titanium carbon black respectively, and graphene and silicon-aluminum-titanium carbon black to send graphene Tire island produces graphene tires, graphene is sent to graphene brake pad island to produce graphene brake pads, graphene lithium titanium rare earth ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com