Low-grade mixed rare earth ore concentrate chemical dressing and chemical dressing waste water resource comprehensively recycling method

A mixed rare earth, low-grade technology, applied in mining wastewater treatment, chemical instruments and methods, ammonium chloride, etc., can solve the problems of large resource loss, no practicability, and difficult comprehensive recovery, and achieves savings in beneficiation costs. The effect of saving acid and alkali consumption and improving the utilization rate of raw ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

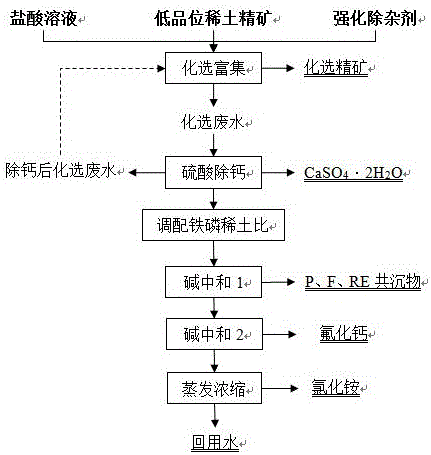

Method used

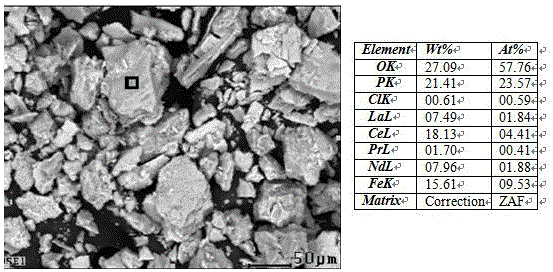

Image

Examples

Embodiment 1

[0029] 100.0g of mixed rare earth concentrate with 51.7% REO and 13.2% CaO, hydrochloric acid solution with a concentration of 4mol / L of hydrogen ion substance and concentrated sulfuric acid with a mass percentage of 92.5% Proportional mix. The solid-to-liquid volume ratio of low-grade mixed rare earth concentrate to hydrochloric acid solution is 1:5; the ratio of concentrated sulfuric acid to hydrochloric acid solution is 10 grams of enhanced impurity remover per liter of hydrochloric acid solution. Stir and dissolve for 180 minutes under the condition of 92°C≤temperature≤95°C. After the dissolution was completed, 67.2 g of chemical separation concentrate and chemical separation wastewater with a mass percentage of REO of 69.85% and a mass percentage of CaO of 0.53% were obtained by filtration.

[0030] Take 100ml of chemical separation waste water, according to H 2 SO 4 The amount of the substance and the amount of the CaO substance in the chemical separation wastewater a...

Embodiment 2

[0033] 100.0g of mixed rare earth concentrate with 54.2% REO and 12.5% CaO, hydrochloric acid solution with a concentration of 3mol / L of hydrogen ion substances and concentrated sulfuric acid with a mass percentage of 98% Proportional mix. The solid-to-liquid volume ratio of low-grade mixed rare earth concentrate to hydrochloric acid solution is 1:4; the ratio of concentrated sulfuric acid to hydrochloric acid solution is 20 grams of enhanced impurity remover per liter of hydrochloric acid solution. Stir and dissolve at a temperature of 95°C for 120 min. After the dissolution, 73.2 g of chemical separation concentrate and chemical separation waste water with a mass percentage of REO of 68.5% and a mass percentage of CaO of 0.83% were obtained by filtration.

[0034] Take 100ml of chemical separation waste water, according to H 2 SO 4 The amount of the substance and the amount of the CaO substance in the chemical separation wastewater are in excess of 40% according to the ...

Embodiment 3

[0037] 100.0g of mixed rare earth concentrate with 48.7% REO and 13.8% CaO, hydrochloric acid solution with a concentration of 2.5mol / L of hydrogen ion substances and concentrated sulfuric acid with a mass percentage of 98% Mix in proportion. The solid-to-liquid volume ratio of low-grade mixed rare earth concentrate to hydrochloric acid solution is 1:6; the ratio of concentrated sulfuric acid to hydrochloric acid solution is 15 grams of enhanced impurity remover per liter of hydrochloric acid solution. Stir and dissolve at a temperature of 95°C for 180 min. After the dissolution, 77.2 g of chemical separation concentrate and chemical separation waste water with REO mass percentage content of 62.1% and CaO mass percentage content of 2.41% were obtained by filtration.

[0038] Take 100ml of chemical separation waste water, according to H 2 SO 4 The amount of the substance and the amount of the CaO substance in the chemical separation wastewater are in excess of 40% according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com