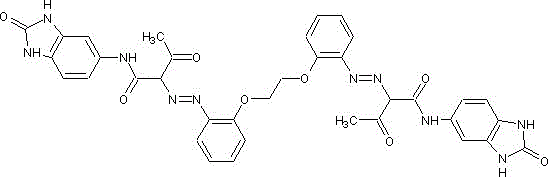

Preparation method of C.I. pigment yellow 180

A technology of pigment yellow and molar ratio, applied in chemical instruments and methods, organic dyes, azo dyes, etc., can solve the problems of high dissolution cost and high ammonia nitrogen value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

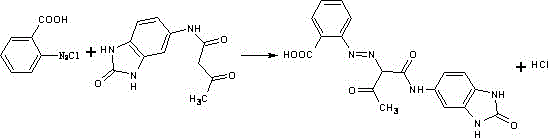

[0066] Add 24.34 kg of water and 12.17 kg of 30% hydrochloric acid into the first beating pot, start stirring, add 13.7 kg of anthranilic acid, and beat at room temperature for half an hour. Finished, spare.

[0067] Add 48.68 kg of water and 24.34 kg of 30% hydrochloric acid into the second beating pot, start stirring, add 25.5 kg of 4-amino-N-(4-carbamoyl) phenylformamide, and beat at room temperature for 1 hour. Finished, spare.

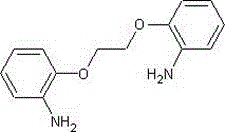

[0068] Add 851.66kg of water and 425.83kg of 30% hydrochloric acid into the diazo pot, start stirring, add 244kg of 1,2-bis(o-aminophenoxy)ethane, beat for 10 minutes, then add 2.44kg of dispersant MF and 1000kg of ice, Beat for 1 hour. spare.

[0069] In the dissolving pot, add 227.7kg of water and 151.8kg of sodium nitrite until completely dissolved.

[0070] Add 3000kg of ice into the diazonium pot, cool down to 0°C, the first diazotization: start to add 345kg of sodium nitrite solution dropwise for the first time, the dropping time is 10~1...

Embodiment 2

[0075] Add 73.02 kg of water and 36.51 kg of 30% hydrochloric acid into the first beating pot, start stirring, add 27.4 kg of anthranilic acid, and beat at room temperature for half an hour. Finished, spare.

[0076] Add 121.7kg of water and 60.85kg of 30% hydrochloric acid into the second beating pot, start stirring, add 51kg of 4-amino-N-(4-carbamoyl)phenylformamide, and beat at room temperature for 1 hour. Finished, spare.

[0077] Add 1703.32kg of water and 547.5kg of 30% hydrochloric acid into the diazo pot, start stirring, add 244kg of 1,2-bis(o-aminophenoxy)ethane, beat for 10 minutes, then add 7.32kg of dispersant MF and 1000kg of ice, Beat for 1 hour. spare.

[0078] In the dissolving pot, add 331.2kg of water and 165.6kg of sodium nitrite until completely dissolved.

[0079] Add 3000kg of ice into the diazonium pot, cool down to 0°C, the first diazotization: start to drop the first 414kg of sodium nitrite solution, the dropping time is 10~15 minutes, the temperat...

Embodiment 3

[0084] Add 50kg of water and 25kg of 30% hydrochloric acid into the first beating pot, start stirring, add 20kg of anthranilic acid, and beat at room temperature for half an hour. Finished, spare.

[0085] Add 85kg of water and 42.5kg of 30% hydrochloric acid in the second beating pot, start stirring, add 38kg of 4-amino-N-(4-carbamoyl)phenylformamide, and beat at room temperature for 1 hour. Finished, spare.

[0086] Add 1278kg of water and 486.67kg of 30% hydrochloric acid into the diazo pot, start stirring, add 244kg of 1,2-bis(o-aminophenoxy)ethane, beat for 10 minutes, then add 4.9kg of dispersant MF and 1000kg of ice, beat 1 hour. spare.

[0087] In the dissolving pot, add 280kg of water and 158.7kg of sodium nitrite until completely dissolved.

[0088] Add 3000kg of ice into the diazonium pot, cool down to 0°C, the first diazotization: start to drop the first 380kg of sodium nitrite solution, the dropping time is 10-15 minutes, the temperature is kept at 0-5°C, Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com