Straw quick crushing device for agricultural production

A crushing system and straw technology, applied in agriculture, agricultural machinery and implements, applications, etc., can solve problems such as air pollution, reduce production efficiency, traffic impact, etc., increase friction resistance and high temperature resistance, improve work efficiency, The effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

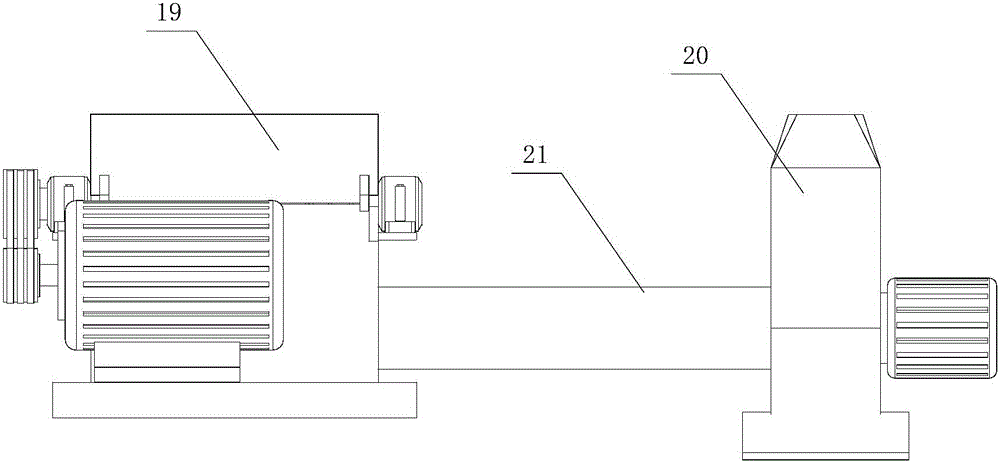

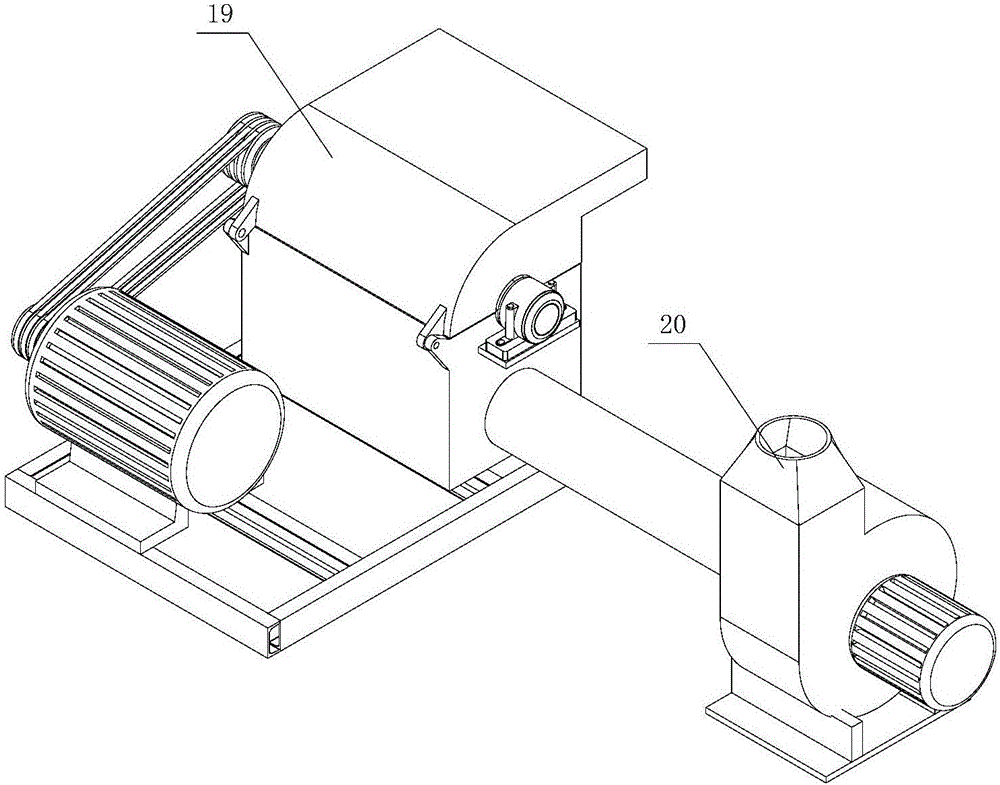

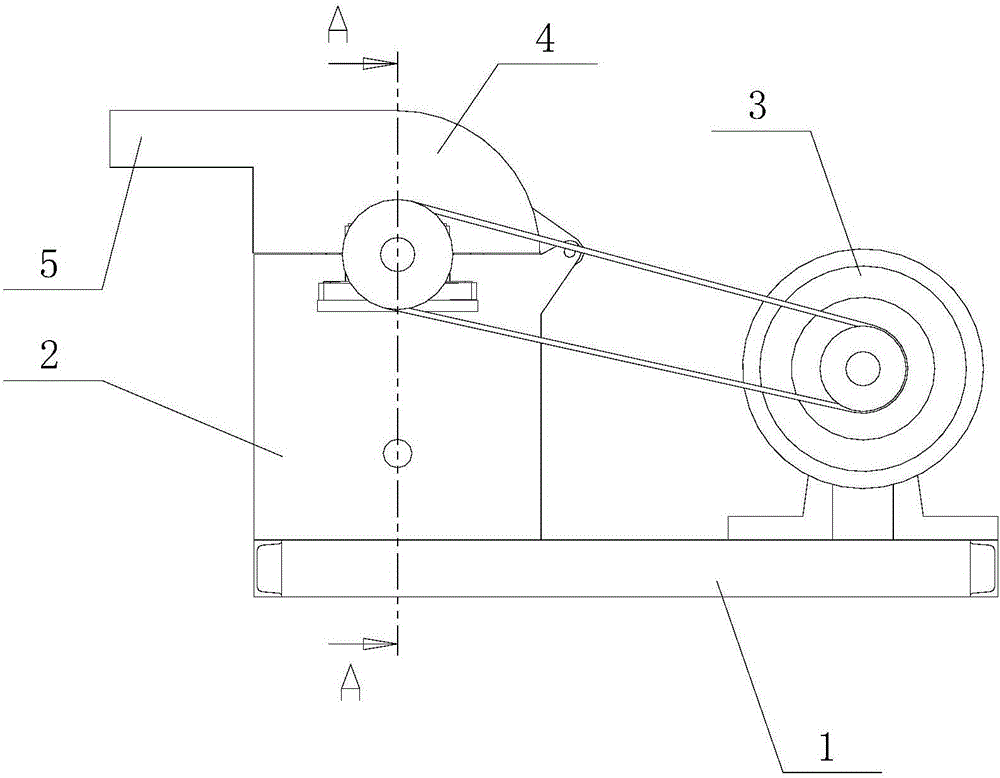

[0031] A straw quick crushing system for agricultural production provided in this embodiment includes a crusher 19 and a conveying fan 20 arranged horizontally for straw crushing, the output port of the crusher 19 is connected to the input port of the conveying fan 20 through a pipeline 21; Crusher 19 includes a support frame 1 arranged horizontally. A crusher base 2 and a motor 3 are arranged side by side on the upper end of the support frame 1. The upper end of the crusher base 2 is provided with an arc end cover 4, and the arc end cover 4 is arranged along the horizontal direction. There is a feed port 5, and a crushing shaft 6 is provided between the crusher base 2 and the arc end cover 4. The crushing shaft 6 is fixed to the crusher base 2 through the bearing seat 7, and the crushing shaft 6 is located at the output of the motor 3. One end on the same side of the shaft is provided with a driving wheel 8, and the driving wheel 8 is connected with the rotating shaft of the m...

Embodiment 2

[0042] This embodiment provides a straw rapid crushing system for agricultural production, the structure of the rapid straw crushing system for agricultural production is exactly the same as that in Embodiment 1, wherein the inner surface of the crusher base 2 is provided with a friction-resistant metal coating , The composition of the friction-resistant metal coating is: carbon: 0.05%, magnesium: 1.7%, vanadium: 3.13%, nickel: 4.6%, niobium: 0.24%, barium: 2.75%, tungsten: 0.23%, titanium: 3.4%, copper: 0.3%, lanthanum: 2.6%, neodymium: 1.8%, promethium: 2.38%, europium: 1.23%, dysprosium: 2.4%, and the balance is iron;

[0043] Wherein the anti-friction metal coating is also mixed with additives, and the composition of the additives is as follows: forsterite: 14 parts, rutile: 11 parts, talcum powder: 32 parts, zircon: 12 parts, nickel powder: 4 parts, copper powder: 3 parts;

[0044] Wherein the preparation method of the friction-resistant metal coating is carried out acco...

Embodiment 3

[0050] This embodiment provides a straw rapid crushing system for agricultural production, the structure of the rapid straw crushing system for agricultural production is exactly the same as that in Embodiment 1, wherein the inner surface of the crusher base 2 is provided with a friction-resistant metal coating , The composition of the friction-resistant metal coating is: carbon: 0.06%, magnesium: 1.8%, vanadium: 3.14%, nickel: 4.8%, niobium: 0.25%, barium: 2.79%, tungsten: 0.24%, titanium: 3.5%, copper: 0.5%, lanthanum: 2.8%, neodymium: 1.9%, promethium: 2.45%, europium: 1.24%, dysprosium: 2.5%, and the balance is iron;

[0051] Wherein the anti-friction metal coating is also mixed with additives, and the composition of the additives is as follows: forsterite: 15 parts, rutile: 12 parts, talcum powder: 35 parts, zircon: 13 parts, nickel powder: 5 parts, copper powder: 4 parts;

[0052] Wherein the preparation method of the friction-resistant metal coating is carried out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com