Preparation method of highland barley barley green rich in superoxide dismutase

A technology of superoxide and barley green, applied in the field of preparation of highland barley barley green, can solve the problems of high operation requirements and operating equipment requirements, no mention of SOD specific values, high production costs and difficult promotion, etc., and achieves no taste. Grassy smell, good operability, clear and bright solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] A preparation method of highland barley green pigment rich in superoxide dismutase is as follows:

[0154] 1) Pretreatment: Harvest 100g of highland barley seedlings up to 20cm in length, remove withered, discolored wheat seedlings, and other weeds, add 2000ml of water to the highland barley seedlings, ultrasonicate twice for 30 minutes each time, and discard the water;

[0155] 2) Sterilization: the pretreated highland barley seedlings are sterilized by saturated steam method, and the sterilization time is 8s;

[0156] 3) Drying and pulverization: vacuum-dry the wheat seedlings after sterilization at a drying temperature of 70° C., and pulverize them to obtain highland barley grass powder;

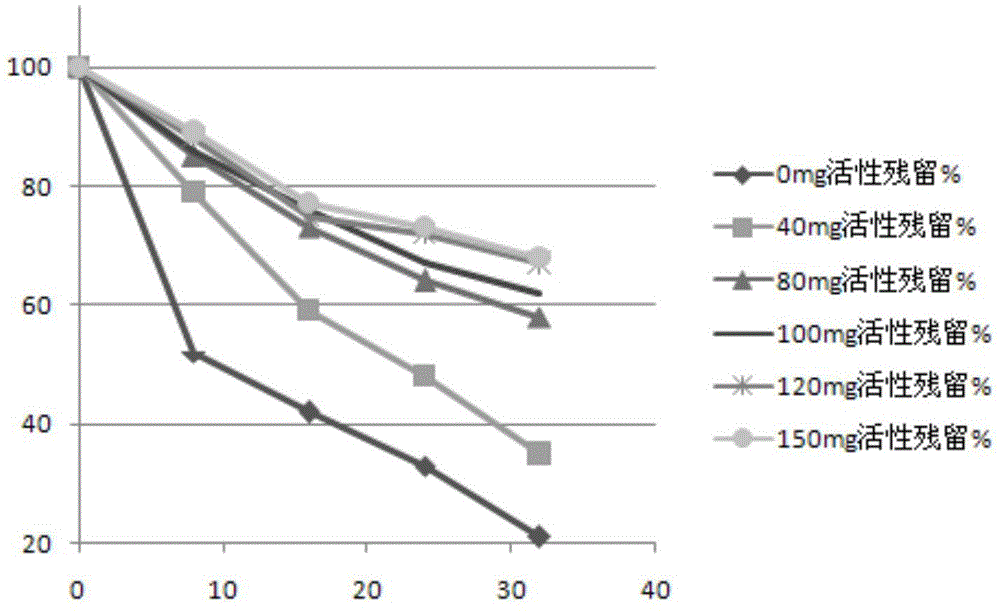

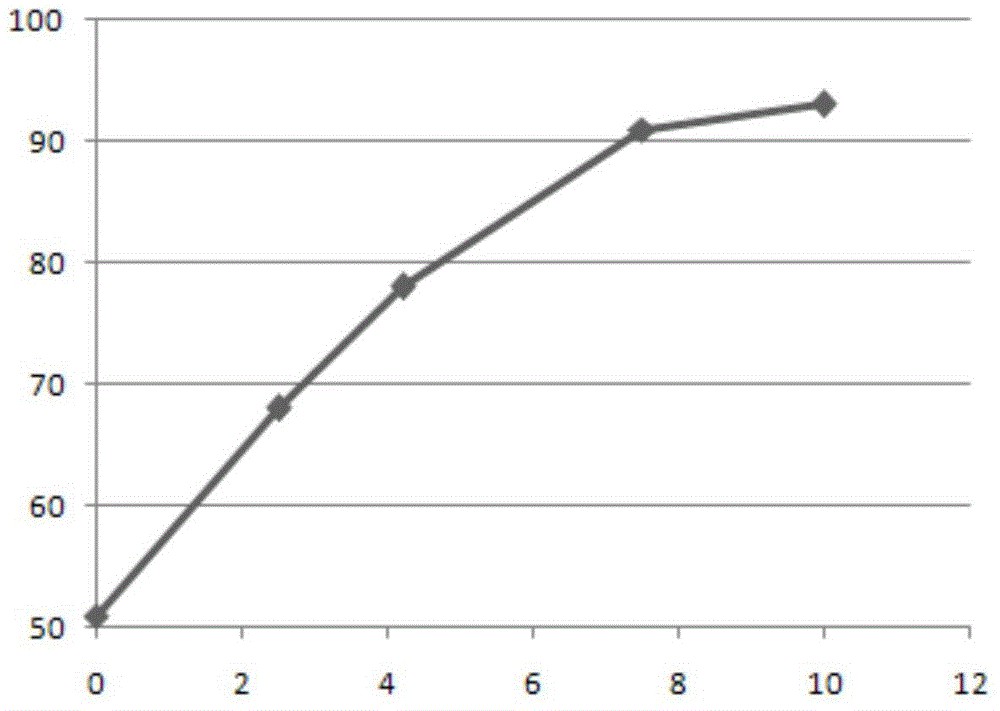

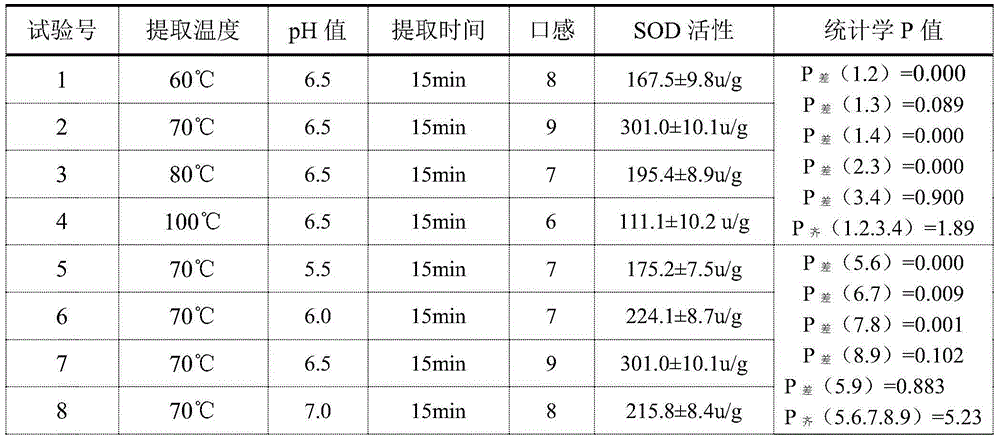

[0157] 4) SOD extraction and separation: add highland barley seedling powder, 1000ml of phosphate buffer solution with pH=6.5, and 160mg of copper gluconate in a constant temperature stirring tank, soak and extract at 100r / min, 70°C for 15min; filter , collect the filtrate for sub...

Embodiment 2

[0163] A preparation method of highland barley green pigment rich in superoxide dismutase is as follows:

[0164] 1) Pretreatment: Harvest 100g of highland barley seedlings up to 40cm long, remove withered, discolored wheat seedlings, and other weeds, add 2000ml of water to the highland barley seedlings, ultrasonicate twice, each time for 30min, and discard the water;

[0165] 2) Sterilization: sterilize the pretreated barley seedlings by saturated steam method, and the sterilization time is 10s;

[0166] 3) Drying and pulverization: vacuum-dry the wheat seedlings after sterilization at a drying temperature of 80° C., and pulverize them to obtain highland barley grass powder;

[0167] 4) SOD extraction and separation: add highland barley seedling powder, 1200ml of phosphate buffer solution with pH=7.0, and 100mg of copper gluconate in a constant temperature stirring tank, soak and extract at 100r / min, 80°C for 10min; filter , collect the filtrate for subsequent use;

[0168]...

Embodiment 3

[0173] A preparation method of highland barley green pigment rich in superoxide dismutase is as follows:

[0174] 1) Pretreatment: Harvest 100g of highland barley seedlings up to 30cm long, remove withered, discolored wheat seedlings, and other weeds, add 2000ml of water to the highland barley seedlings, ultrasonicate twice for 30 minutes each time, and discard the water;

[0175] 2) Sterilization: sterilize the pretreated barley seedlings by saturated steam method, and the sterilization time is 9s;

[0176] 3) Drying and pulverization: vacuum-dry the wheat seedlings after sterilization at a drying temperature of 60° C., and pulverize them to obtain highland barley grass powder;

[0177] 4) SOD extraction and separation: Add highland barley seedling powder, 800ml phosphate buffer solution with pH=6.0, and 200mg copper gluconate in a constant temperature stirring tank, soak and extract at 100r / min, 60°C for 20min; filter, Collect the filtrate for subsequent use;

[0178] 5) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com