Method for preparing light mung bean complex beverage and utilizing byproducts thereof

A technology of by-products and mung beans, which is applied in the field of preparation of light mung bean compound drinks and the utilization of by-products, can solve the problems of single raw materials and insufficient refreshing taste, and achieve the effects of simple operation, better clarity and uniform tissue state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

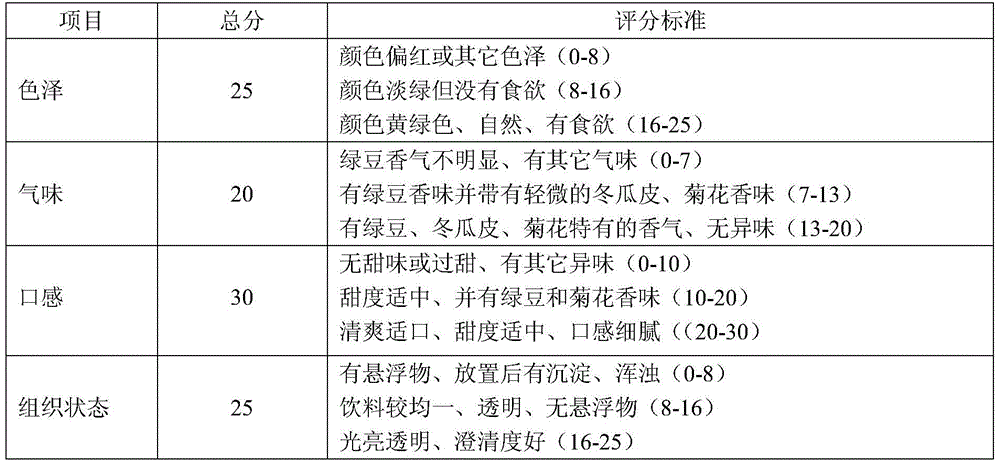

Examples

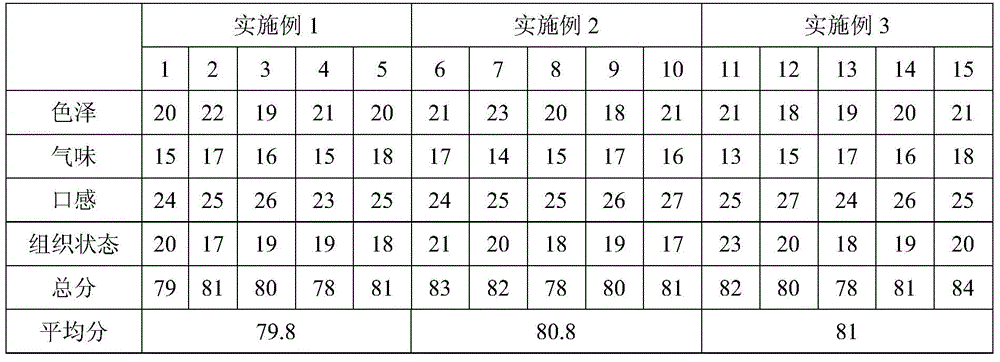

Embodiment 1

[0031] 1.1. Pretreatment of wax gourd rind

[0032] Heat 20kg of wax gourd rind in 140kg of water to 80°C and extract for 20 minutes, filter through a 200-mesh filter and retain the filtrate to obtain the wax gourd rind extract;

[0033] 1.2. Mung bean extraction

[0034] Soak 100kg mung beans in 1000kg water at room temperature for 2 hours, boil and extract, keep boiling for 5 minutes after boiling, let stand for 5 minutes, and take the supernatant;

[0035] 1.3. Filtration

[0036] The supernatant is quickly filtered through a 200-mesh filter, and the filtrate is retained to obtain mung bean clear juice;

[0037] 1.4. Deployment

[0038] Add 65kg of white granulated sugar, 104kg wax gourd rind extract, 57kg soybean polysaccharide, 1.3kg carboxymethylcellulose sodium and 0.39kg mung bean essence to 1000kg mung bean clear juice for deployment to obtain mung bean beverage;

[0039] 1.5 Homogeneous

[0040] Homogenize the mung bean beverage with a high-pressure homogenizer,...

Embodiment 2

[0048] 1.1. Pretreatment of wax gourd rind

[0049] Heat 30kg of wax gourd rind in 270kg of water to 90°C and extract for 15 minutes, filter through a 200-mesh filter and retain the filtrate to obtain the wax gourd rind extract;

[0050] 1.2. Mung bean extraction

[0051] Soak 200kg mung beans in 2200kg water at room temperature for 150min, boil and extract, keep boiling for 3min after boiling, let stand for 7min, and take the supernatant;

[0052] 1.3. Filtration

[0053] The supernatant is quickly filtered through a 200-mesh filter, and the filtrate is retained to obtain mung bean clear juice;

[0054] 1.4. Deployment

[0055] Add 182kg of white granulated sugar, 234kg wax gourd peel extract, 52kg soybean polysaccharide, 3.1kg carboxymethylcellulose sodium and 1.04kg mung bean essence to 2000kg mung bean clear juice and prepare to obtain mung bean beverage;

[0056] 1.5 Homogeneous

[0057] Homogenize the mung bean beverage with a high-pressure homogenizer, the homogeni...

Embodiment 3

[0065] 1.1. Pretreatment of wax gourd rind

[0066] Heat 40kg of wax gourd rind in 400kg of water to 100°C and extract for 10 minutes, filter through a 200-mesh filter and retain the filtrate to obtain the wax gourd rind extract;

[0067] 1.2. Mung bean extraction

[0068] Soak 300kg mung beans in 3600kg water at room temperature for 3 hours, boil, keep boiling for 2 minutes after boiling, let stand for 8 minutes, and take the supernatant;

[0069] 1.3. Filtration

[0070] Filter the supernatant quickly through a 100-mesh filter, retain the filtrate, and obtain mung bean clear juice;

[0071] 1.4. Deployment

[0072] Add 273kg of white granulated sugar, 468kg wax gourd skin extract, 13kg soybean polysaccharide, 3.7kg carboxymethylcellulose sodium and 1.45kg mung bean essence to the filtered 3000kg mung bean clear juice to prepare the mung bean beverage;

[0073] 1.5 Homogeneous

[0074] Use a high-pressure homogenizer to homogenize the mung bean beverage for 5 minutes, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com