Preparation and application of a polyethylene glycol functionalized magnetic carbon nanotube

A technology of magnetic carbon nanotubes and polyethylene glycol, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problems of high hydrophobicity and poor biocompatibility on the surface of carbon nanotubes, and achieve rapid The effects of separation and enrichment, stable properties and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

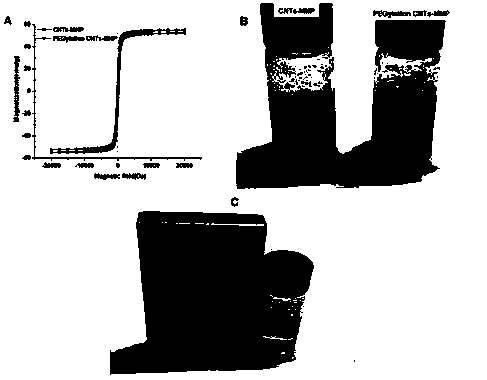

[0033] Example 1: Preparation method of polyethylene glycol functionalized magnetic carbon nanotube composite material

[0034] (1) Weigh 400mg of the original carbon nanotubes and disperse them in 50mL of 65-68% concentrated nitric acid, and react with magnetic stirring at 60°C for 7 hours. Use a microporous membrane with a pore size of 0.45um to filter through a Buchner funnel and continuously wash with distilled water until pH=7, vacuum drying at 50°C to obtain carboxylated multi-walled carbon nanotubes (CNTs-COOH);

[0035] (2) Take 150mg CNTs-COOH and 810mg FeCl of the above oxidized carbon nanotubes 3 Disperse in 40-50mL polyethylene glycol containing trisodium citrate (150mg), sodium acetate (3.6g) and polyethylene glycol 2000 (1.0g), and ultrasonically disperse, the ultrasonic dispersion time is 2h; transfer the liquid Into the reaction kettle, heat to 200 for reaction 10, wash with water and ethanol, and freeze-dry to obtain magnetic carbon nano (CNTs-COOH-MNP);

[0036] (3...

Embodiment 2

[0037] Example 2: Preparation method of polyethylene glycol functionalized magnetic carbon nanotube composite material

[0038] (1) Weigh 400mg of original carbon nanotubes and disperse them in 50mL 65-68% concentrated nitric acid, and react with magnetic stirring at 60°C for 7 hours. Use a 0.45um microporous filter membrane to filter through a Buchner funnel and continuously wash with distilled water Dry under vacuum until pH=7 at 50°C to obtain oxidized multi-walled carbon nanotubes (CNTs-COOH);

[0039] (2) Take 150mg CNTs-COOH and 1g FeCl of the above oxidized carbon nanotubes 3 Disperse in 40-50mL polyethylene glycol containing trisodium citrate (150mg), sodium acetate (3.6g) and polyethylene glycol 2000 (1.0g), and ultrasonically disperse, the ultrasonic dispersion time is 2h; transfer the liquid Into the reaction kettle, heat to 200 for reaction 10, wash with water and ethanol, and freeze-dry to obtain magnetic carbon nano (CNTs-COOH-MNP);

[0040] (3) Weigh 80 mg of magnetic...

Embodiment 3

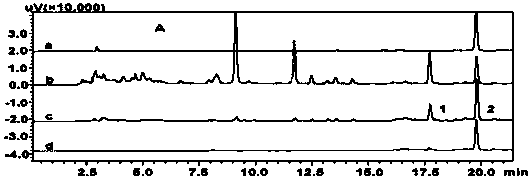

[0041] Example 3: Polyethylene glycol functionalized magnetic carbon nanotube composite material is used as a dispersive solid phase extraction adsorbent for the separation of active small molecules of Angelica sinensis and the quality control of Angelica sinensis:

[0042] The standard sample of Z-ligustilide was purchased from Chengdu Munster Biotechnology Co., Ltd., and the mass concentration of Z-ligustilide was 0.625-7.5ug / mL prepared with methanol (the Z-ligustilide concentration was 0.625, 1.25, 2.50, 5.00, 7.50) -Ligustilide standard sample solution) Z-ligustilide standard sample solution for HPLC determination, the specific experimental process is as follows: prepare Z-ligustrum with mass concentrations of 0.625, 1.25, 2.50, 5.00, 7.50 with methanol The standard sample solution of this lactone is measured by HPLC (the instrument model is LC-20AD, the manufacturer is Shimadzu Corporation, and the instrument is equipped with Tianhe C18 column (250×4.6mm, 5um particle size);...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com