Method for preparing spherical In2S3 nanometer materials by aid of ionic liquid

A nanomaterial and ionic liquid technology, applied in the field of material chemistry, achieves the effect of simple preparation method, wide application range and perfect product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

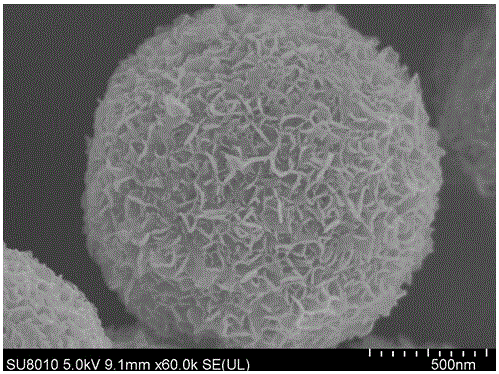

[0032] Curd In 2 S 3 The preparation method of nanomaterials, using ionic liquid aqueous solution as medium, adopts hydrothermal method to synthesize In with a diameter of about 2 μm 2 S 3 Microspheres are assembled from nano-sheets with a thickness of about 20nm, and the thickness of the nano-sheets is highly uniform. The ionic liquid of the present invention assists in the preparation of curdled In 2 S 3 The method for nanomaterials, the concrete steps of its preparation are:

[0033] (1) Add water to the container, and then add In(NO 3 ) 3 4.5H 2 O, thioacetamide and ionic liquid, the mass range of adding ionic liquid is 2.5g~7g. Stir the mixed solution evenly;

[0034] (2) Put the container at 160°C to react for a period of time, the reaction time ranges from 12h to 96h, after the reaction is completed, the flower-shaped In 2 S 3 nanomaterials;

[0035] (3) Naturally cool to room temperature, and the obtained precipitates are repeatedly washed by ultrasonic cen...

Embodiment 1

[0043] 1. Preparation: wash the polytetrafluoroethylene reaction kettle (volume 100mL) with tap water and distilled water for 3 times respectively, and dry it for later use;

[0044] 2. Reaction steps: Add 50 mL of water to the reaction kettle treated in step 1, and then add 0.4 mmolIn(NO 3 ) 3 4.5H 2 O, 1.6 mmol thioacetamide and 7.5 g of [Bmim] BF 4 . After stirring the above solution evenly, put it into the reaction kettle and react at 160°C for 48h;

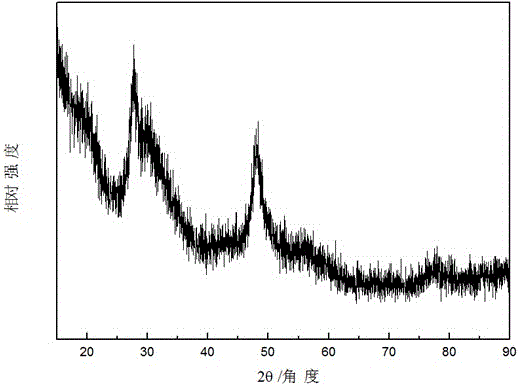

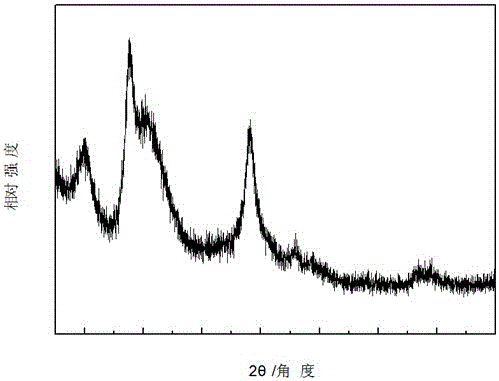

[0045] 3. Post-treatment: after the reaction is finished, then naturally cool to room temperature. The obtained precipitates were washed with distilled water and absolute ethanol several times by ultrasonic centrifugation, and dried in vacuum at 60°C for 8 hours. Then carefully transfer to a sample tube and store in a dark, dry environment. The appearance of the product is uniform yellow, and it is determined by X-ray powder diffractometer (XRD) that there is only In 2 S 3 , no impurity, XRD pattern see Picture 1-1 ....

Embodiment 2

[0047] 1, preparatory work: with embodiment 1;

[0048] 2. Reaction steps: add 50mL water to the reaction kettle treated in step 1, then add 0.4mmolIn(NO 3 ) 3 4.5H 2 O, 1.6 mmol thioacetamide and 5 g of [Bmim] BF 4 . After stirring the above solution evenly, put it into the reaction kettle and react at 160°C for 48h;

[0049] 3, aftertreatment: with embodiment 1. The appearance of the product is uniform yellow, and the XRD spectrum is shown in Picture 1-1 , field emission scanning electron micrographs see Figure 2-2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com