Preparation method for green colorant and green glass for shielding ultraviolet and obtained product

A colorant and green technology, applied in the field of colorants, can solve the problems of air pollution, color instability, high cost of iron-manganese coloring, etc., and achieve the effect of cost reduction, color stability, and good shielding of ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

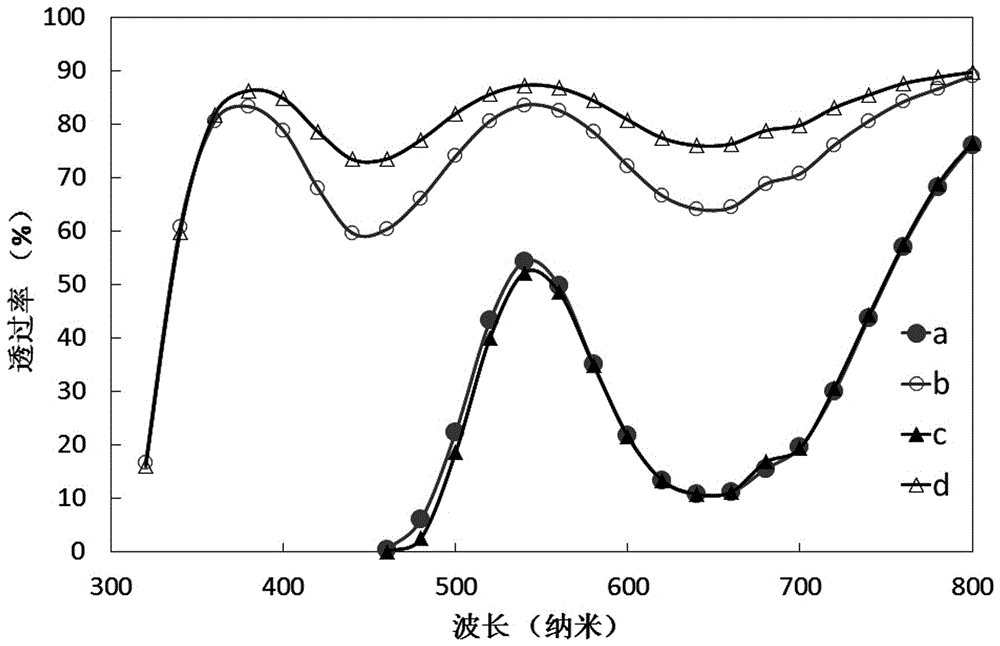

Image

Examples

Embodiment 1

[0039] 1. Preparation of amino-functionalized silica sand

[0040] 1.1. Add 6g of silica sand and 1.08g of CTAB into a 250ml Erlenmeyer flask, then add 100ml of distilled water, place in a water bath constant temperature oscillator (rotating frequency 185~225rpm) at 60°C for 10min, then add 30ml of 0.3M NaOH, and then add 4.5ml of TEOS dropwise. Continue to shake the reaction at this temperature for 3 hours, then take it out, wash it with distilled water five times, and dry it.

[0041] 1.2. Repeat the above steps 4 times to obtain coated silica sand 5 times. Dry the silica sand at 90°C for 3 hours, heat it up to 550°C at a rate of 1°C / min and calcinate it for 6 hours to remove hexadecyltrimethylammonium bromide. Porous silica modified silica sand.

[0042] 1.3. Take 5g of the above-mentioned porous silica-modified silica sand, put it in a 250ml three-necked flask, add 100ml of anhydrous toluene and 3ml of 3-aminopropyltriethoxysilane (APTES), condense and reflux at 115°C for...

Embodiment 2

[0047] 1. Preparation of amino-functionalized silica sand: same as Example 1.

[0048] 2, the preparation of coloring agent: get the Cr(NO of 150ppm 3 ) 3 Solution 50ml, adjust the pH of the solution to 4.5, add 0.5g of amino-functionalized silica sand, absorb at a constant temperature of 25°C for 1 hour, filter after adsorption, and dry the product at 90°C to obtain the colorant, Cr 3+ The adsorption capacity is 5.84mg / g amino-functionalized silica sand. In order to meet the required amount of glass preparation, this operation was repeated 40 times to obtain the required amount of colorant.

[0049] 3. Preparation of green glass: Referring to Example 1, the difference is that the colorant used is the colorant of this example, and the resulting glass is green.

Embodiment 3

[0051] 1. Preparation of amino-functionalized silica sand

[0052] 1.1 Put 1.08g of cetyltrimethylammonium bromide, 6g of silica sand, and 100mL of water on a shaker at 60°C for 10 minutes (rotating frequency 185~225rpm), then add 30ml of 0.3M sodium hydroxide solution, and then Add 4.5mL tetraethyl orthosilicate dropwise, and continue to shake the reaction at this temperature for 3h, so that the silicon dioxide formed by the hydrolysis of tetraethyl orthosilicate is coated on the surface of the silica sand; after the reaction, wash, filter, and take The precipitate was dried at 90°C for 3 hours, and the dried precipitate was heated to 550°C at a heating rate of 1°C / min and calcined for 6 hours to remove cetyltrimethylammonium bromide, resulting in porous silica-modified silica sand. After testing, its specific surface area is 260.56m 2 / g.

[0053] 1.2 Take 2g of the above-mentioned porous silica-modified silica sand, put it in a 250ml three-neck flask, add 100ml of anhydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com