Light-weight environment-friendly cement board and preparation process thereof

A preparation process, cement board technology, applied in the direction of hydraulic material layered products, lamination, building components, etc., can solve the problems of long production cycle, high cost, cumbersome process, etc., to achieve short production cycle and low manufacturing cost Low, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

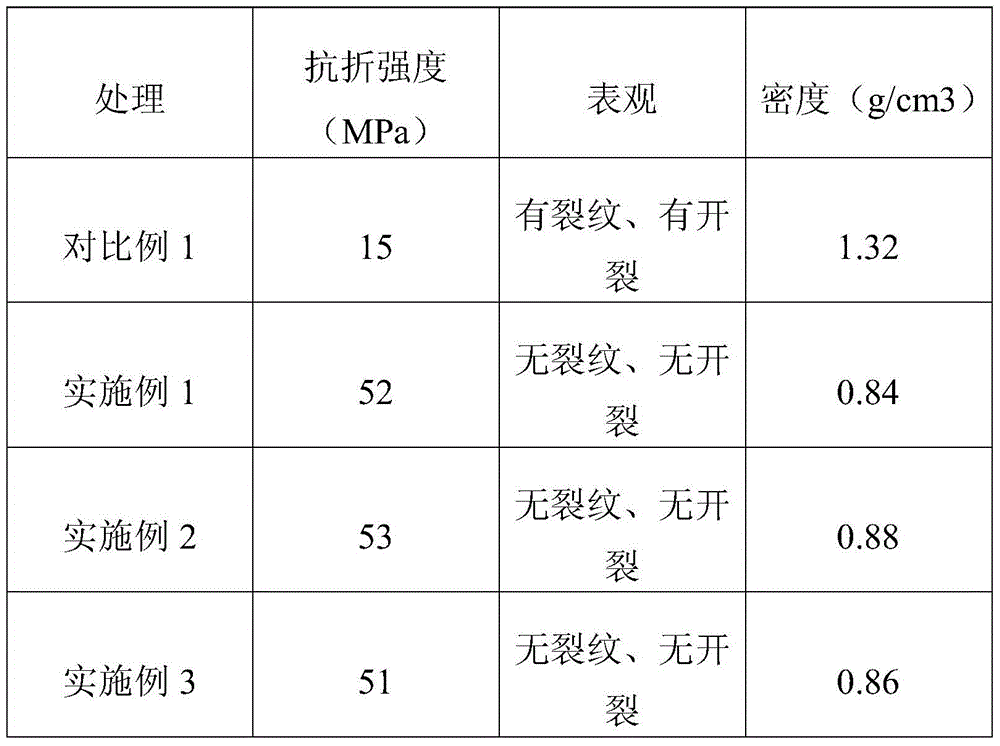

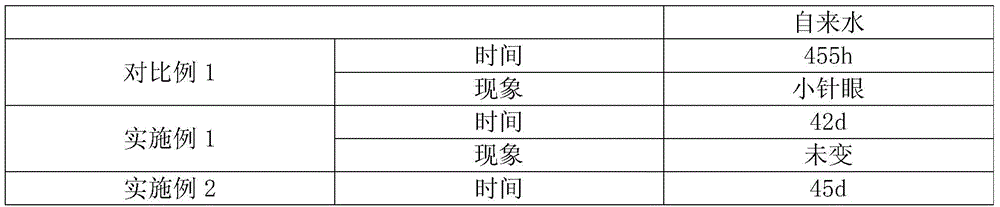

Embodiment 1

[0028] A kind of lightweight environment-friendly cement board, comprises base material layer, grid cloth layer, middle material layer, grid cloth layer and fabric layer, and its weight ratio is 5:0.5:2:0.5:5; Described base material layer 1. The fabric layer comprises the following components by weight: 90 parts of sulphoaluminate cement, 0.1 part of modifier and 5 parts of water; said modifier comprises the following components by weight: butyl naphthalene sulfonic acid 3 parts of sodium, 10 parts of ammonium carbonate, 5 parts of magnesium hydroxide, 5 parts of ammonium chloride and 1 part of sodium carboxymethyl cellulose; the middle material layer comprises the following components by weight: sulfoaluminate cement 90 parts, 5 parts of plant stalks, 5 parts of wood chips and 5 parts of water; the mesh cloth layer uses 160g of alkali-resistant glued mesh cloth.

[0029] The preparation technology of described lightweight environment-friendly cement board, concrete steps are...

Embodiment 2

[0037] A kind of lightweight environment-friendly cement board, comprises base material layer, grid cloth layer, middle material layer, grid cloth layer and fabric layer, and its weight ratio is 5:0.5:2:0.5:5; Described base material layer 1. The fabric layer comprises the following components by weight: 95 parts of sulphoaluminate cement, 0.4 parts of modifier and 10 parts of water; said modifier comprises the following components by weight: butyl naphthalene sulfonic acid 5 parts of sodium, 15 parts of ammonium carbonate, 15 parts of magnesium hydroxide, 8 parts of ammonium chloride and 3 parts of sodium carboxymethylcellulose; the middle material layer comprises the following components by weight: sulfoaluminate cement 95 parts, 15 parts of plant stalks, 15 parts of wood chips and 15 parts of water; the mesh cloth layer adopts 160g of alkali-resistant glued mesh cloth.

[0038] The preparation technology of described lightweight environment-friendly cement board, concrete s...

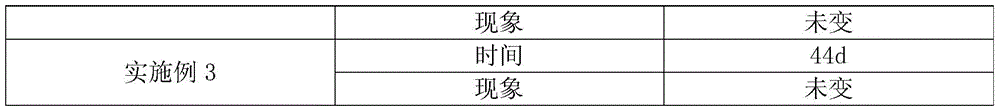

Embodiment 3

[0046] A kind of lightweight environment-friendly cement board, comprises base material layer, grid cloth layer, middle material layer, grid cloth layer and fabric layer, and its weight ratio is 5:0.5:2:0.5:5; Described base material layer 1. The fabric layer comprises the following components by weight: 92 parts of sulphoaluminate cement, 0.2 parts of modifier and 8 parts of water; said modifier comprises the following components by weight: butyl naphthalene sulfonic acid 4 parts of sodium, 12 parts of ammonium carbonate, 10 parts of magnesium hydroxide, 6 parts of ammonium chloride and 2 parts of sodium carboxymethyl cellulose; the middle material layer comprises the following components by weight: sulfoaluminate cement 92 parts, 10 parts of plant straw, 10 parts of wood chips and 10 parts of water; the grid cloth layer adopts 160g of alkali-resistant glued grid cloth.

[0047] The preparation technology of described lightweight environment-friendly cement board, concrete st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com