Preparation method of p-nitro-o-cresol

A technology of nitro-o-cresol and nitro-o-cresol, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low yield of nitro-o-cresol and many reaction by-products , to achieve high purity, easy operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

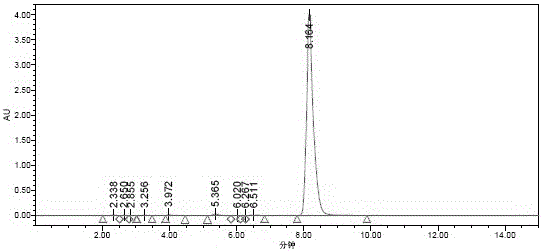

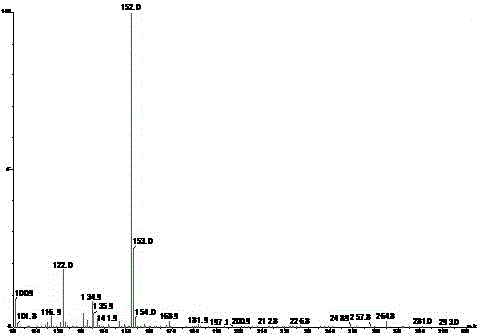

[0023] Add 60.8g of p-nitro-o-toluidine (0.4mol), 200g of sodium hydroxide and 600ml of water into a 2000ml four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, heat to 115°C and keep the reaction for 24 hours Then stop heating, add 500ml of water, filter, slowly add hydrochloric acid to the filtrate to adjust the pH of the reaction solution to about 4, and precipitate a yellow solid, wait to cool to room temperature and filter, filter and wash the filter cake three times with 1000ml of water, drain, and store at 50°C Dry in a vacuum oven for 4 hours to obtain a yellow p-nitrophenol solid with a yield of 98.1%, qualitative by mass spectrometry, ESI-MS (m / z): 152.0 [M-H] - ( figure 1 ); Determination of its content by HPLC method, from Table 1 and figure 2 It can be known that the present embodiment p-nitro-o-cresol content is 99.12%.

[0024] Table 1 Peak results

[0025] .

Embodiment 2

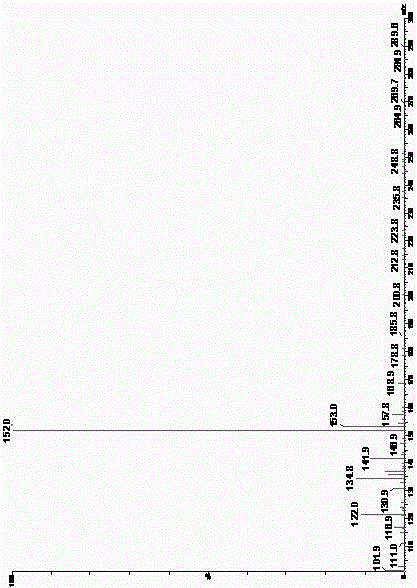

[0027] Add 30.4g of p-nitro-o-toluidine (0.2mol), 100g of sodium hydroxide and 900ml of water into a 2000ml four-necked flask equipped with a thermometer, agitator, and reflux condenser, heat to reflux, and stop after reflux for 50 hours Heat, add 500ml of water, filter, slowly add sulfuric acid to the filtrate to adjust the pH of the reaction solution to about 3, precipitate a yellow solid, wait to cool to room temperature, filter, filter, wash the filter cake with 1000ml of water three times, drain, and vacuum dry at 50°C Dry in the oven for 4 hours to obtain a yellow p-nitrophenol solid, yield 98.5%, qualitative by mass spectrometry, ESI-MS (m / z): 152.0 [M-H] - ( image 3 ), using HPLC method to determine its content, from Table 2 and Figure 4 It can be seen that the present embodiment p-nitro-o-cresol content is 99.39%.

[0028] Table 2 Peak results

[0029] .

Embodiment 3

[0031] Add 6.08g of p-nitro-o-toluidine (0.04mol) and 20g of potassium hydroxide and 380ml of water into a 1000ml four-necked flask equipped with a thermometer, a stirrer and a reflux condenser, heat to 95°C and keep the reaction for 72 hours Then stop heating, filter, slowly add phosphoric acid to the filtrate to adjust the pH of the reaction solution to about 5, and precipitate a yellow solid. After cooling to room temperature, filter, wash the filter cake with 100ml water for three times, drain, and place in a vacuum oven at 50°C. Dry for 4 hours to obtain p-nitrophenol, yield 96.5%, ESI-MS (m / z): 152.0[M-H] - ( Figure 5 ), using HPLC method to determine its content, from Table 3 and Figure 6 It can be known that the present embodiment p-nitro-o-cresol content is 99.03%.

[0032] Table 3 Peak results

[0033] .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap