Isoforskolin preparing method

A technology for forskolin and isoforskolin, which is applied in the field of preparation of high-purity isoforskolin, can solve the problems of low content of the active ingredient isforskolin, meet the requirements of low reaction conditions and the like, and has high yield , the effect of high crystallization yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Investigation of reaction conditions

[0025] Using forskolin as raw material, using particle size: 200-400 mesh, pH value (100g / L, 25℃): 9.0-10.0 basic alumina catalyst, choose dichloromethane, tetrahydrofuran, methanol, ethanol, benzene As the reaction solvent, the effect of isoforskolin preparation at room temperature was investigated; the reaction vessel was sealed with nitrogen gas; the acetyl group rearrangement reaction was carried out by mechanical stirring. After the reaction is completed, filter, soak and wash the catalyst with the amount of catalyst (kg): washing solvent (L)=1:1.5 methanol (MeOH), combine the filtrate and distill to obtain the crude product;

[0026] Reaction solvent

[0027] Through the comparison of different solvents, it is found that the reaction solvent has a great influence on the preparation method of the present invention. Tetrahydrofuran, methanol and ethanol are selected as the reaction solvent, and the reaction speed is ver...

Embodiment 2

[0029] The method for preparing Isoforskolin described in this embodiment specifically includes the following steps:

[0030] (1) Forskolin as raw material, particle size: 200-400 mesh, pH value (100g / L, 25°C): 9.0-10.0 basic alumina catalyst, dichloromethane (DCM) solvent;

[0031] (2) Under suitable conditions: ①Raw material dosage: catalyst dosage: solvent dosage=1g:20g:25ml; ②Temperature 15℃; ③Time 48h; ④The reaction vessel is sealed with nitrogen; ⑤The acetyl group is rearranged by mechanical stirring. reaction;

[0032] (3) After completing the reaction, filter, use catalyst amount (kg): washing solvent (L)=1:1.5 methanol (MeOH) to soak and wash the catalyst, combine the filtrate and distill to obtain the crude product;

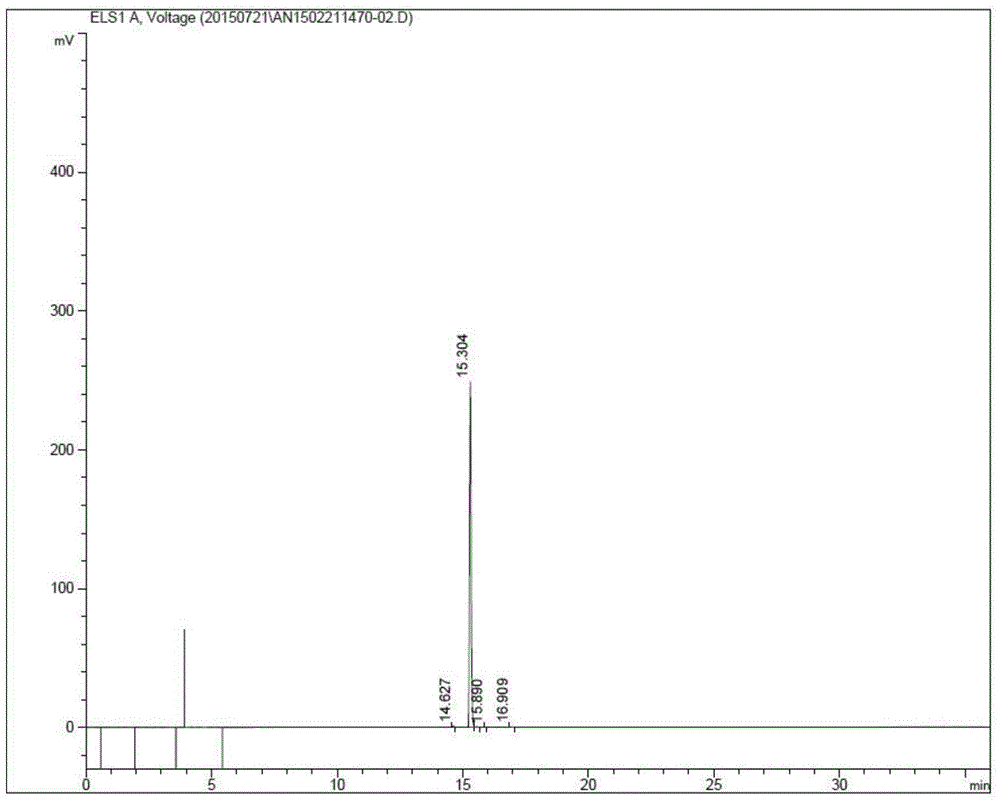

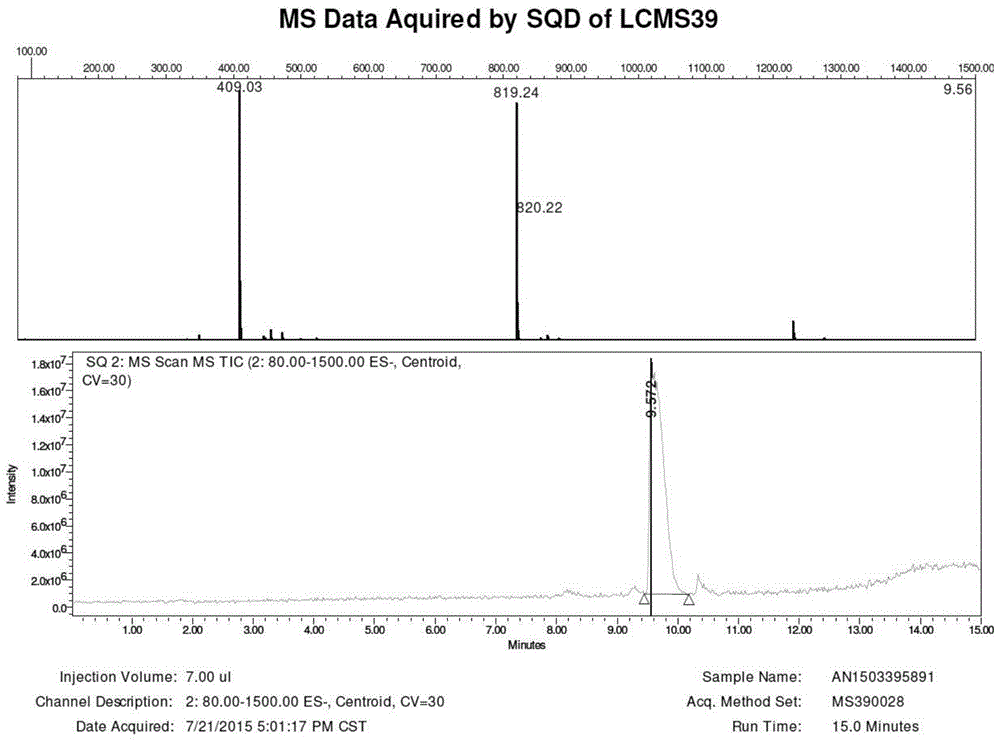

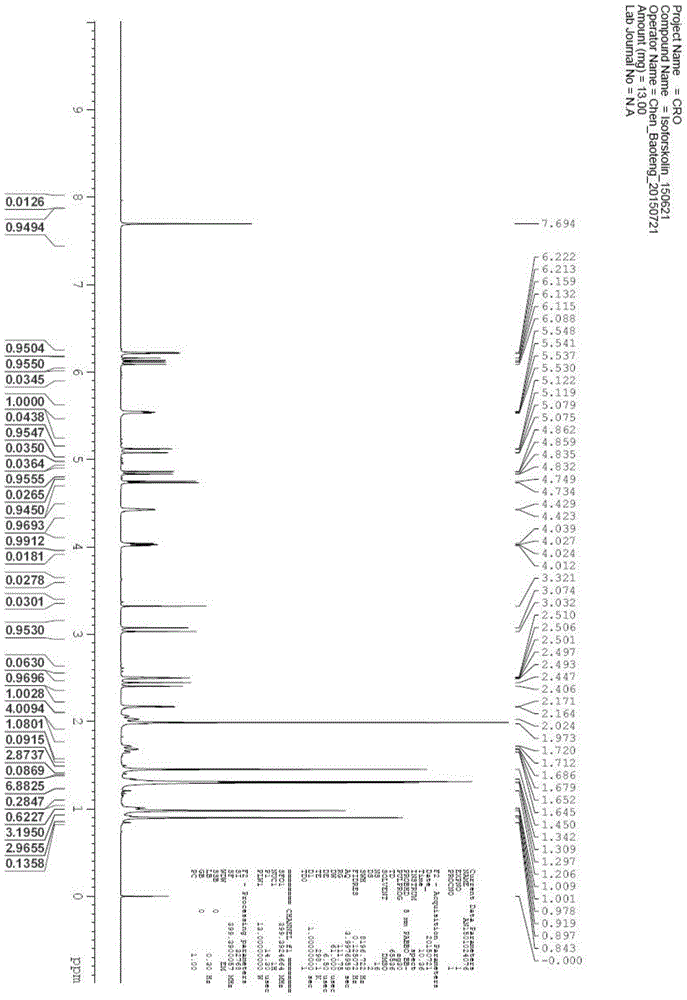

[0033] (4) Purification by secondary crystallization, the first crystallization purification, the solvent ratio (volume ratio) is ethyl acetate (EA): petroleum ether (PE) = 1:2, the amount of solvent is crude product (kg): crystallization solvent (L)=1:9, heat...

Embodiment 3

[0052] The method for preparing Isoforskolin described in this embodiment specifically includes the following steps:

[0053] (1) Forskolin as raw material, particle size: 200-400 mesh, pH value (100g / L, 25°C): 9.0-10.0 basic alumina catalyst, dichloromethane (DCM) solvent;

[0054] (2) Under suitable conditions: ① Quantity of raw materials: quantity of catalyst: quantity of solvent=1g:20g:25ml; ②temperature 40℃; ③time 72h; ④reaction vessel is sealed with nitrogen; ⑤rearrangement of acetyl groups is carried out by mechanical stirring reaction;

[0055] (3) After completing the reaction, filter, use catalyst amount (kg): washing solvent (L)=1:1.5 methanol (MeOH) to soak and wash the catalyst, combine the filtrate and distill to obtain the crude product;

[0056] (4) Purification by secondary crystallization, the first crystallization purification, the solvent ratio (volume ratio) is ethyl acetate (EA): petroleum ether (PE) = 1:2, the amount of solvent is crude product (kg): crystalliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com