Preparation method of temperature-sensitive liquid embolic material for long-term development in situ gelation

A temperature-sensitive, in-situ gel technology, applied in surgery, tissue regeneration, medical science, etc., can solve the problems of easy loss of mixed-type contrast agent, hidden safety hazards of reactive-type contrast agent, and high diagnostic cost, and achieve good biological safety. Sexuality, convenient review, no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

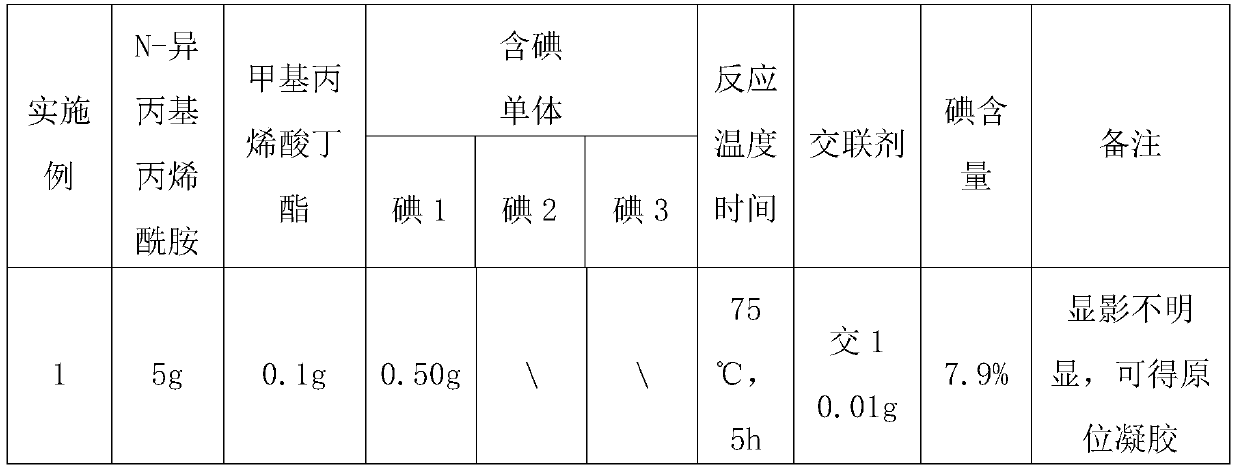

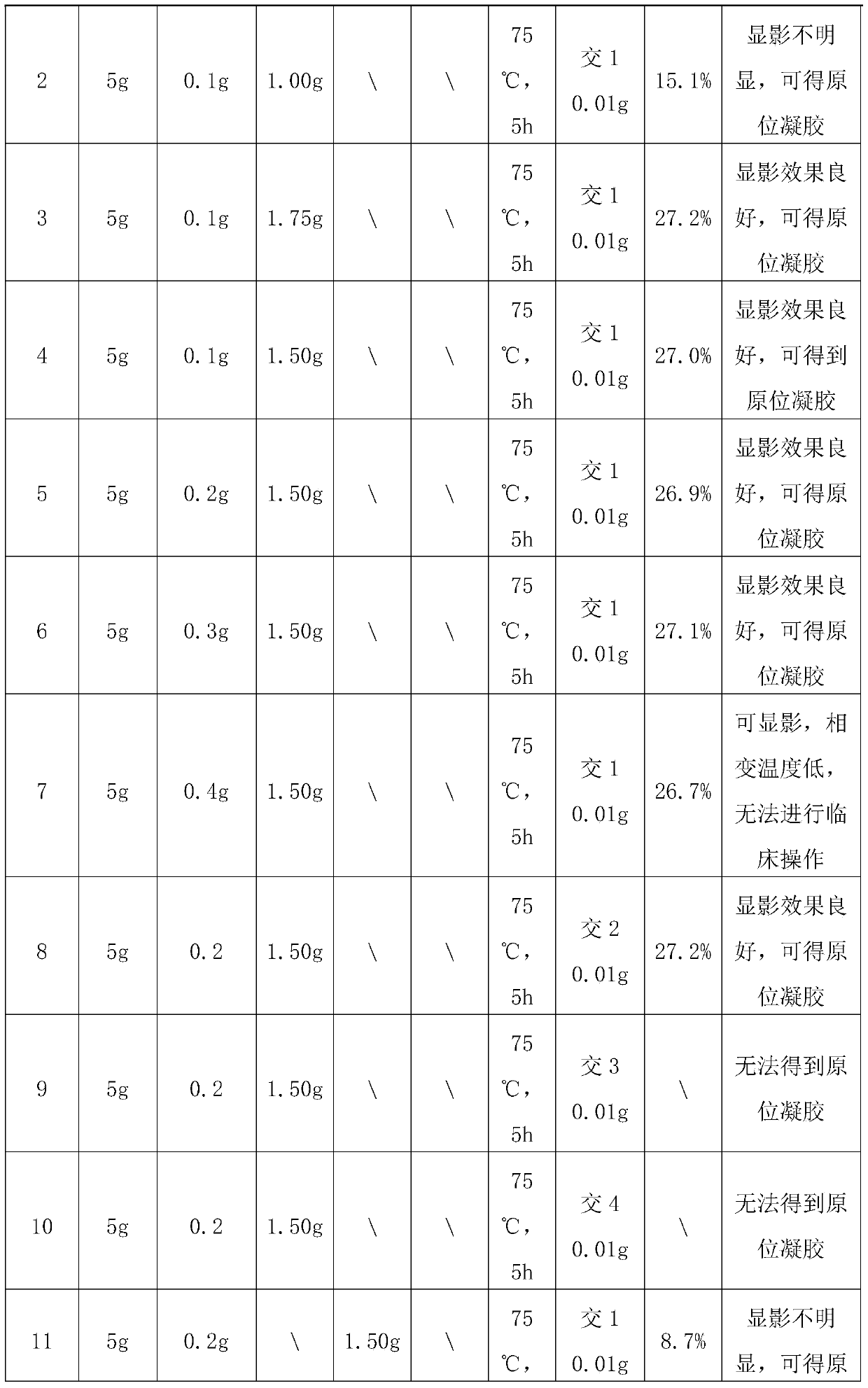

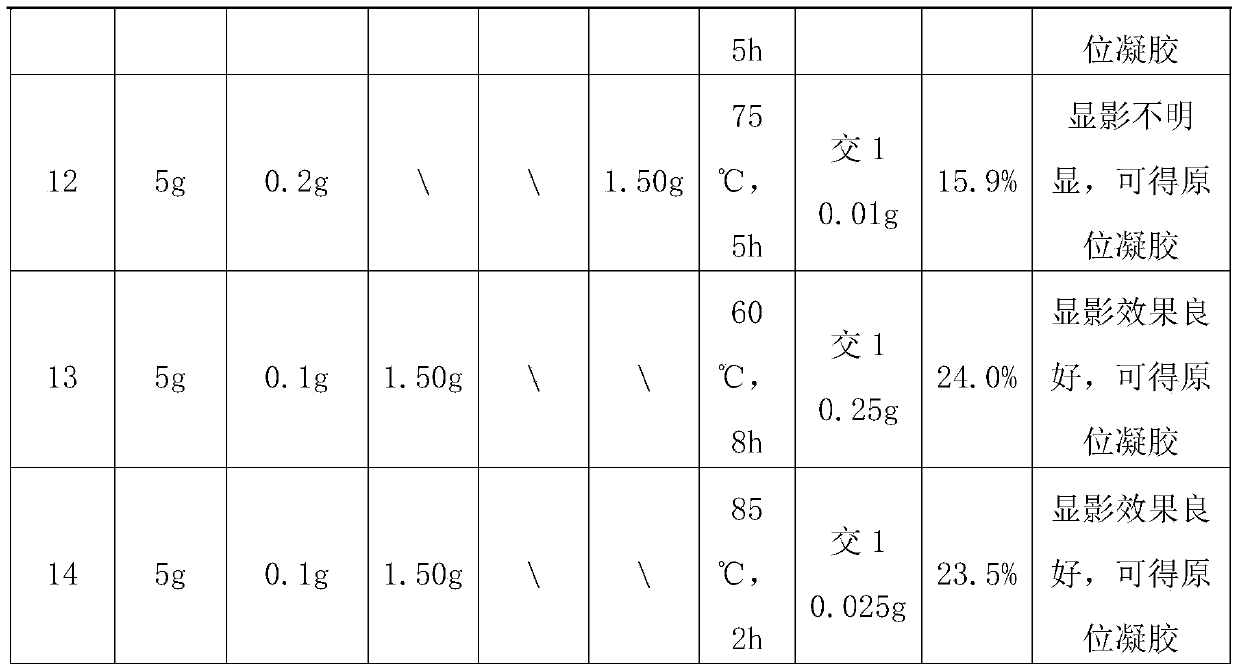

[0025] Recrystallize N-isopropylacrylamide (NIP), take 5g of the treated NIP, butyl methacrylate, and iodine-containing monomers, heat the reaction in dioxane under reflux conditions, and pass N 2 , adding an initiator and a crosslinking agent, and reacting for a certain period of time to obtain a terpolymer.

[0026] The temperature-sensitive copolymer is repeatedly washed in water, purified, and dried; the dried product is dissolved in water for injection according to a certain proportion, and sterilized to obtain an in-situ gelling temperature-sensitive liquid embolism material.

[0027] Data settings in each embodiment are as follows:

[0028]

[0029]

[0030]

[0031] In the table, iodine 1 is acryloyl triiodobenzoate, iodine 2 is sodium iodide, and iodine 3 is triiodobenzoic acid.

[0032] Cross 1 is N,N-methylenebisacrylamide, cross 2 is tetraethylene glycol dimethacrylate, cross 3 is trimethylolpropane triacrylate, cross 4 is ethylene glycol diacryloyl este...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com