Click chemistry based metal-organic framework cross-linking membrane and preparation method and application thereof

A metal-organic framework and chemical cross-linking technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of affecting membrane performance, poor compatibility between MOFs materials and organic materials, MOFs membranes Hard materials and other problems, to avoid pollution and removal problems, good selective separation effect, excellent flexibility and film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 metal organic framework NH 2 -Synthesis of UiO66

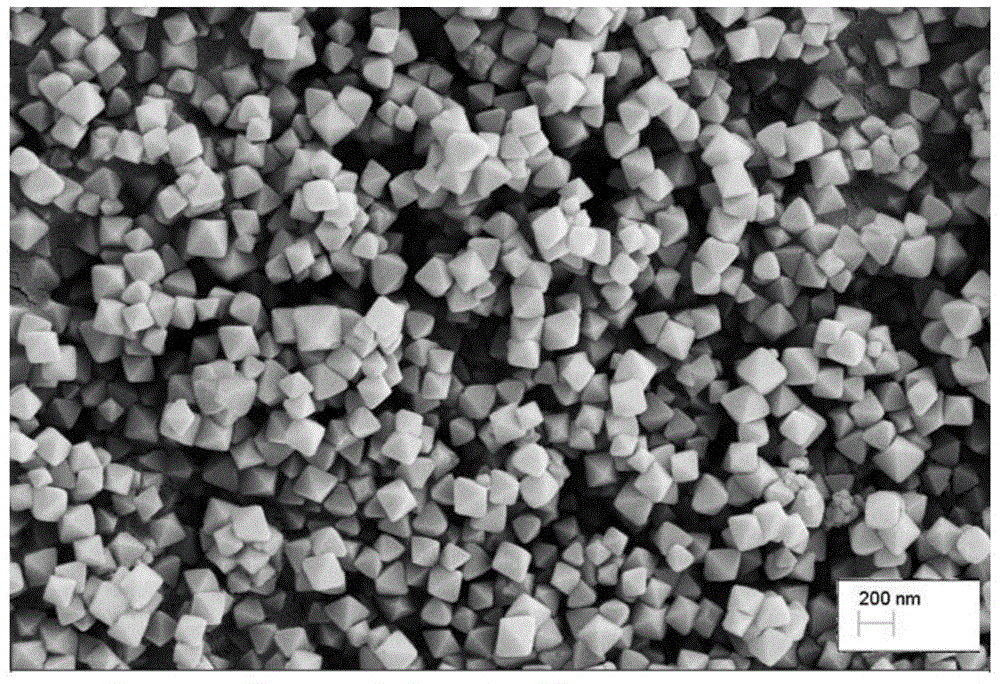

[0058] Dissolve the organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, and acetic acid in N,N-dimethylformamide solvent, keep the temperature at 120°C for 24 hours, and cool down to room temperature to obtain light yellow nano-sized crystals, centrifuge, Drying; wherein the ratio of organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, acetic acid and N,N-dimethylformamide solvent addition is 0.04mmol: 0.04mmol: 2mmol: 1.6ml, the obtained crystal See in description figure 1 .

Embodiment 2

[0059] Example 2 metal organic framework (NH 2 ) 2 - Synthesis of UiO67

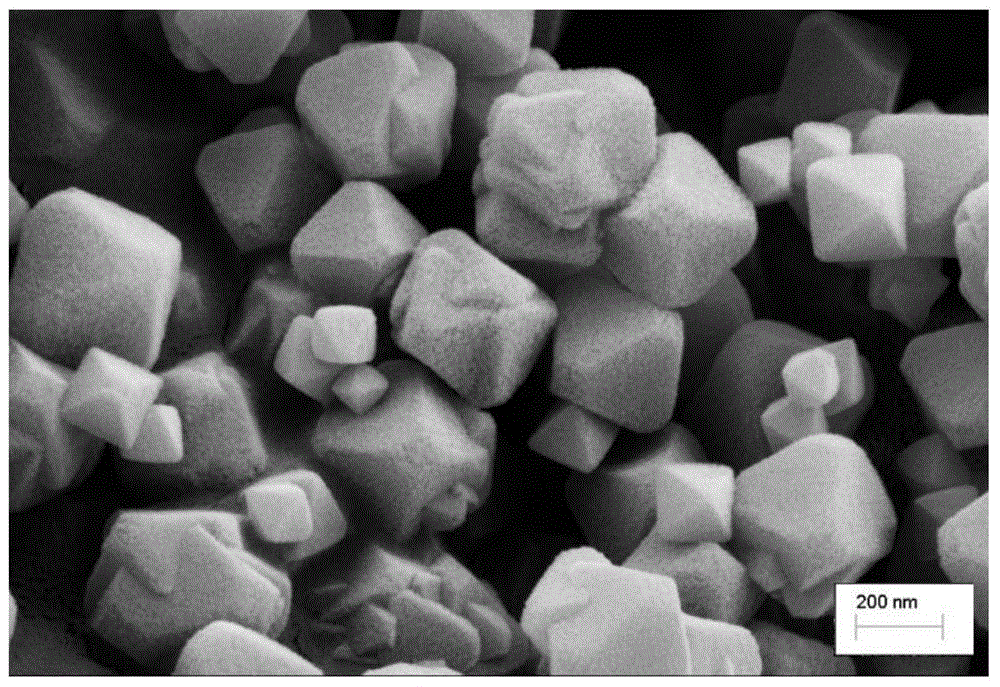

[0060] Dissolve the organic ligand 2,2-diaminobiphenyldicarboxylic acid, zirconium tetrachloride, and acetic acid in N,N-dimethylformamide solvent, keep the temperature at 120°C for 24 hours, and cool down to room temperature to obtain yellow nanoscale crystals. Centrifuge and dry; the ratio of organic ligand 2,2-diaminobiphenyldicarboxylic acid, zirconium tetrachloride, acetic acid and N,N-dimethylformamide solvent is 0.26mmol: 0.26mmol: 447ul: 15ml , the obtained crystal morphology is shown in figure 2 .

Embodiment 3

[0061] Example 3 metal organic framework NH 2 -Synthesis of MIL-101(Al)

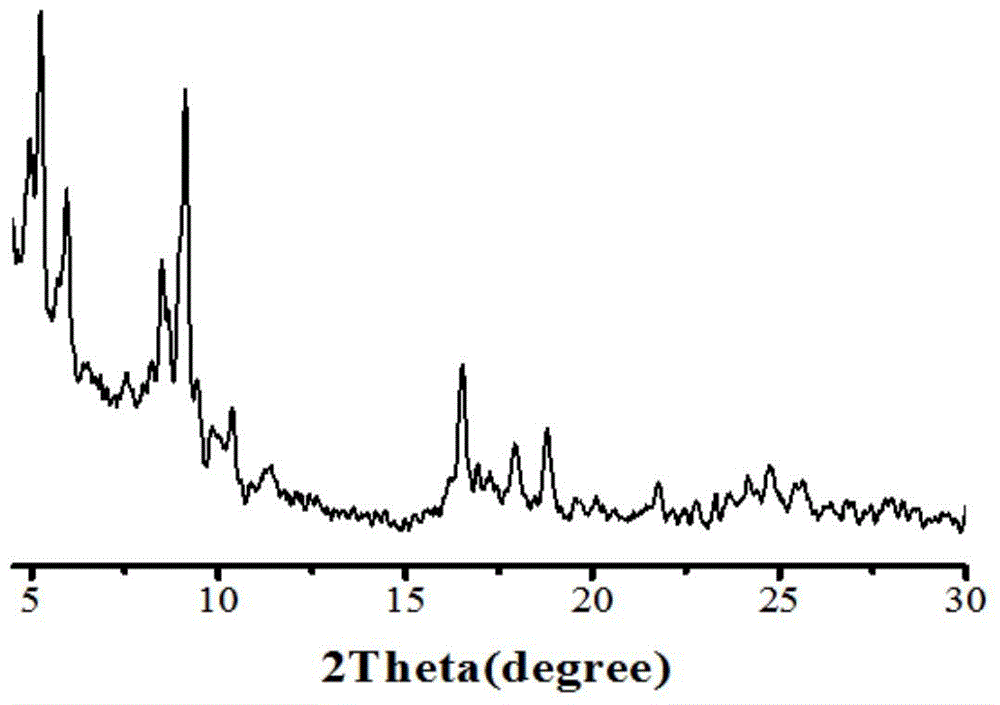

[0062] The organic ligand 2-aminoterephthalic acid (1.09g, 6mmol) and aluminum trichloride hexahydrate (0.96g, 4mmol) were dissolved in 20mL of DMF, placed in a crystallization axe, kept at 110°C for 16h, and then to room temperature, gray nanoscale crystals were obtained, centrifuged, washed with DMF and ethanol in sequence, and dried at 120°C for 24h to obtain NH 2 -MIL-101(Al) crystal powder, see XRD results image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com