Aperture-adjustable cellulose and montmorillonite nano-composite carrier material and preparation method thereof

A carrier material and nanocomposite technology, applied in the field of cellulose and montmorillonite nanocomposite carrier materials and their preparation, can solve the problem of hindering the loading of active substances and the reaction process, failing to achieve efficient utilization of active substances, and uneven size of porous carrier materials and other problems, to achieve the effect of good load effect, low density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

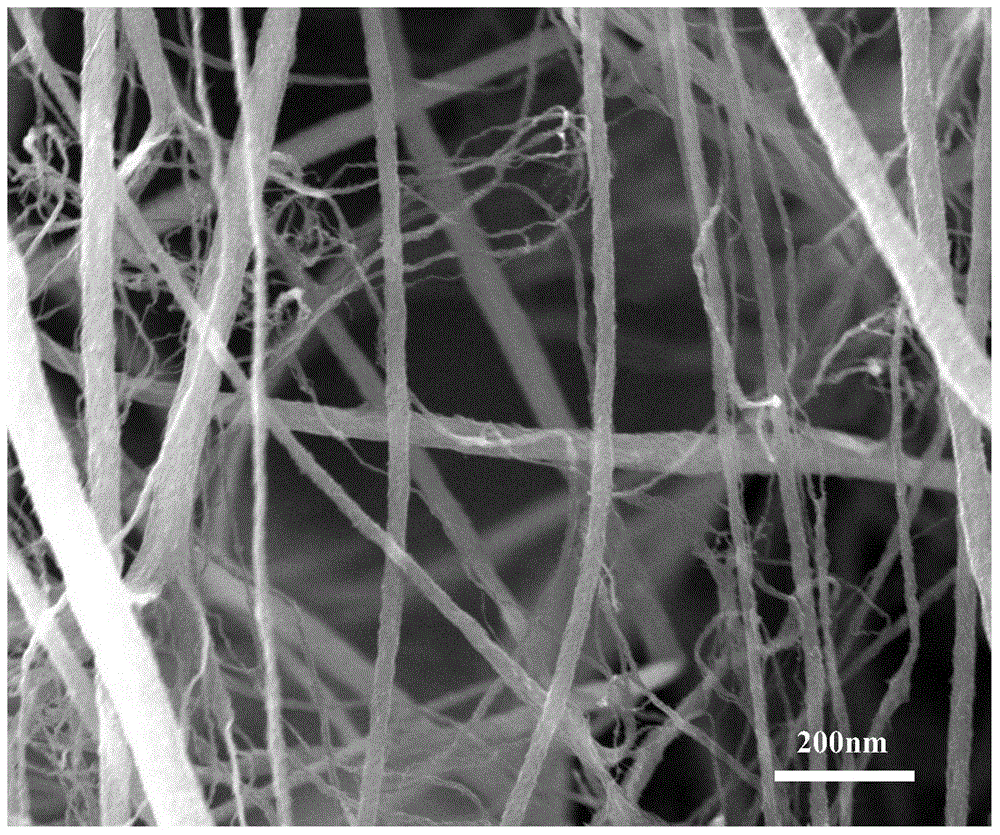

Embodiment 1

[0030] The preparation method of the cellulose and montmorillonite nanocomposite carrier material with adjustable aperture of the present invention comprises the following steps:

[0031] (1) According to the mass ratio of eucalyptus pulpboard and sulfuric acid solution of 1:20, 30g of bleached eucalyptus pulpboard was added to 64wt% sulfuric acid solution, and acid hydrolysis was carried out at a temperature of 45°C and a rotation speed of 400rpm React for 30 minutes, after hydrolysis is complete, add deionized water for static layering, and then remove the supernatant;

[0032] (2) adding water to the lower mixed solution obtained in step (1) and repeatedly standing until the mixed solution no longer settles and stratifies, then transfers the obtained suspension to a dialysis bag, and washes it with flowing deionized water for 3 days;

[0033] (3) Place the suspension obtained after washing in step (2) in a centrifuge for centrifugation, the centrifugation speed is 6000 rpm,...

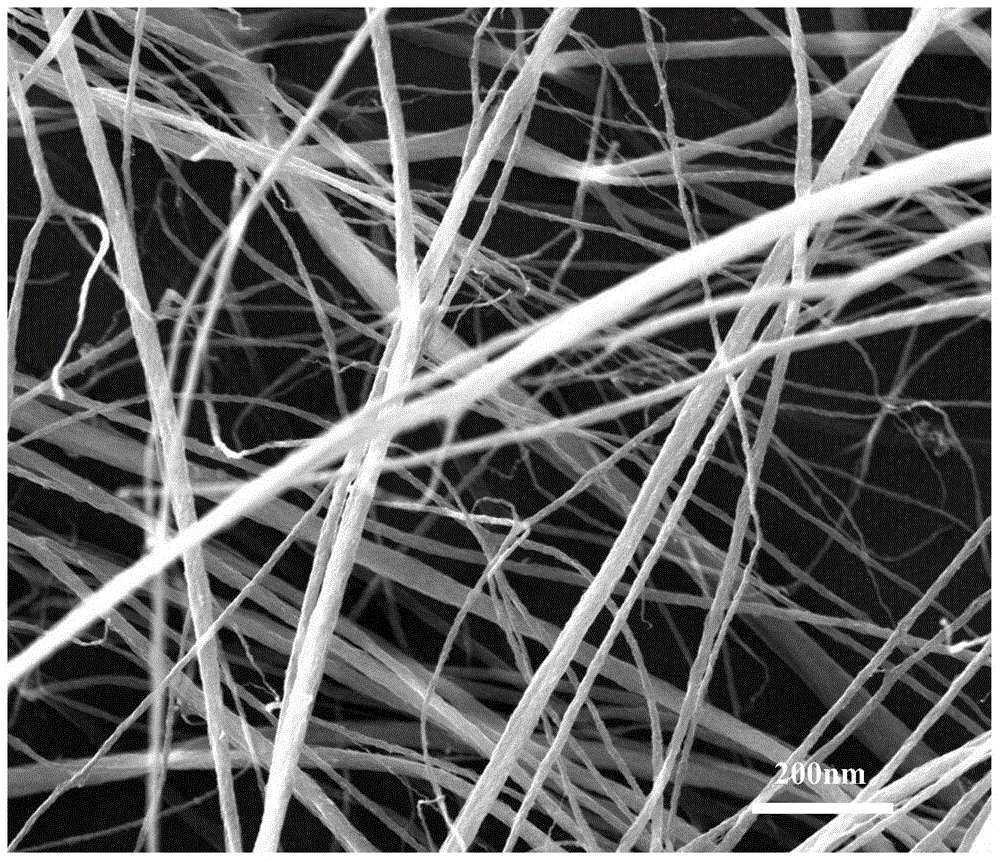

Embodiment 2

[0038] The preparation method of the cellulose and montmorillonite nanocomposite carrier material with adjustable aperture of the present invention comprises the following steps:

[0039] (1) According to the mass ratio of eucalyptus pulpboard and sulfuric acid solution of 1:20, 30g of bleached eucalyptus pulpboard was added to 64wt% sulfuric acid solution, and acid hydrolysis was carried out at a temperature of 45°C and a rotation speed of 400rpm React for 30 minutes, after hydrolysis is complete, add deionized water for static layering, and then remove the supernatant;

[0040] (2) adding water to the lower mixed solution obtained in step (1) and repeatedly standing until the mixed solution no longer settles and stratifies, then transfers the obtained suspension to a dialysis bag, and washes it with flowing deionized water for 3 days;

[0041] (3) Place the suspension obtained after washing in step (2) in a centrifuge for centrifugation, the centrifugation speed is 6000 rpm,...

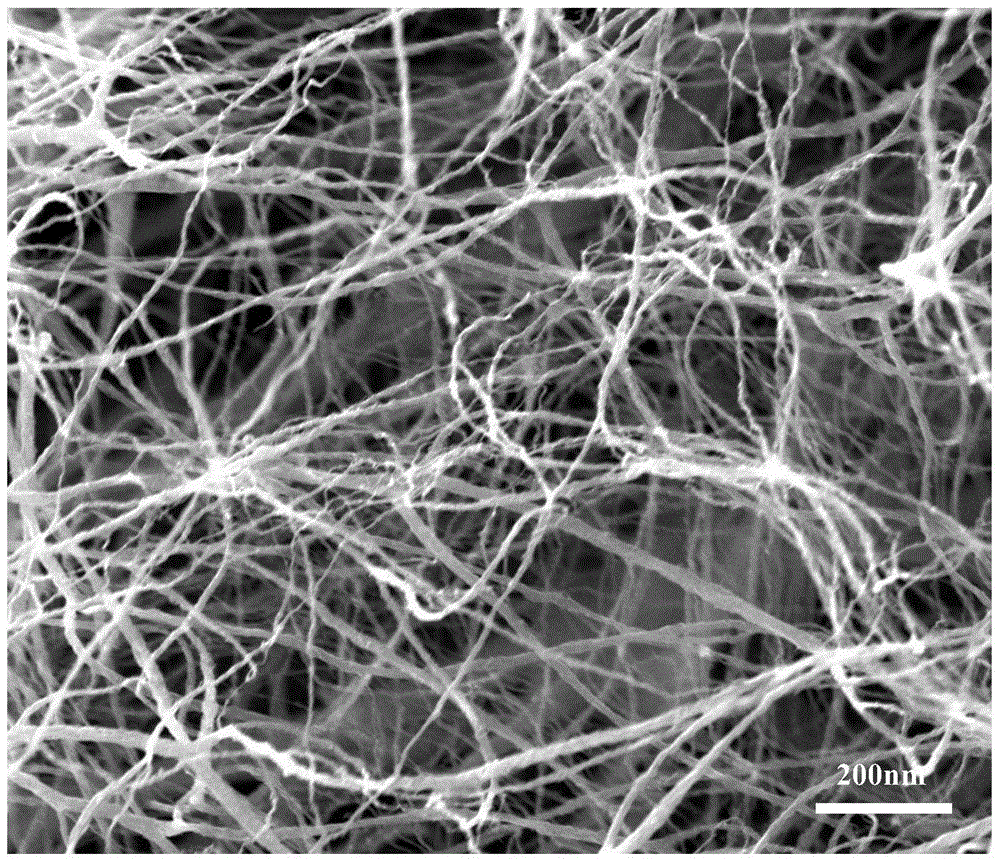

Embodiment 3

[0046] The preparation method of the cellulose and montmorillonite nanocomposite material with adjustable aperture of the present invention comprises the following steps:

[0047] (1) according to the mass ratio 1:20 of cotton fiber and sulfuric acid solution, the cotton fiber that 30g bleaching process is joined in the 64wt% sulfuric acid solution, is that 45 ℃, rotating speed are acid hydrolysis reaction 30 minutes under the condition of 400rpm at temperature, After the hydrolysis is completed, add deionized water for static stratification, and then remove the supernatant;

[0048] (2) adding water to the lower mixed solution obtained in step (1) and repeatedly standing until the mixed solution no longer settles and stratifies, then transfers the obtained suspension to a dialysis bag, and washes it with flowing deionized water for 3 days;

[0049] (3) Place the suspension obtained after washing in step (2) in a centrifuge for centrifugation, the centrifugation speed is 6000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com