Silicone acrylic emulsion modified magnesium-containing inorganic adhesive for straws and preparation method of silicone acrylic emulsion modified magnesium-containing inorganic adhesive

A technology of inorganic adhesives and silicone-acrylic emulsions, applied in the directions of inorganic adhesives, adhesives, adhesive additives, etc., can solve the problems of poor water resistance, warping deformation of straw boards, reduced strength, etc., to improve water resistance, avoid Warp deformation and improved deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

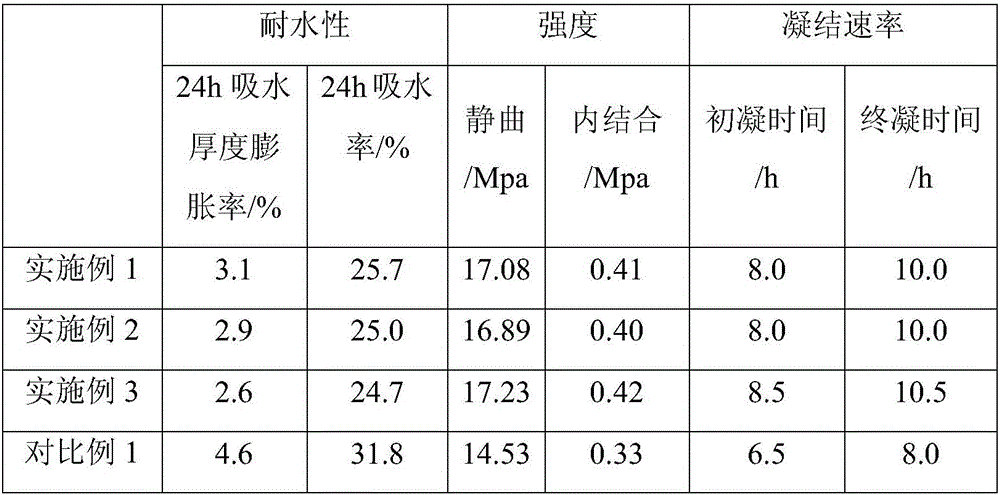

Examples

Embodiment 1

[0033] An embodiment of the magnesium-based inorganic adhesive modified with silicon-acrylic emulsion for straw of the present invention and its preparation method, the preparation method of the adhesive comprises the following steps:

[0034] (1) 167 parts by weight of water are placed in the reaction kettle, heated up to 60° C., adding 100 parts by weight of magnesium chloride hexahydrate (wherein the mass fraction of magnesium chloride is 46%) and stirring at a constant speed for 10 minutes to form a transparent magnesium chloride solution, Stirring speed is 250r / min;

[0035] (2) in above-mentioned magnesium chloride solution, slowly add the magnesium sulfate heptahydrate of 61 parts by weight and stir at a constant speed for 20 minutes;

[0036] (3) Then add 218 parts by weight of light-burned magnesia (wherein the mass fraction of magnesia is 85%) in the reactor, and stir at a constant speed for 15 minutes;

[0037] (4) Slowly add 10 parts by weight of silicon acrylic e...

Embodiment 2

[0040] An embodiment of the magnesium-based inorganic adhesive modified with silicon-acrylic emulsion for straw of the present invention and its preparation method, the preparation method of the adhesive comprises the following steps:

[0041] (1) 184 parts by weight of water are placed in the reactor, the temperature is raised to 55°C, and 100 parts by weight of magnesium chloride hexahydrate (wherein the mass fraction of magnesium chloride is 46%) is added and stirred at a constant speed for 8 minutes to form transparent magnesium chloride Solution, stirring speed is 300r / min;

[0042] (2) in above-mentioned magnesium chloride solution, slowly add the magnesium sulfate heptahydrate of 51 parts by weight and stir at a constant speed for 15 minutes;

[0043] (3) Then add 223 parts by weight of light-burned magnesia (wherein the mass fraction of magnesia is 85%) in the reactor, and stir at a constant speed for 15 minutes;

[0044] (4) slowly join the silicon acrylic emulsion (...

Embodiment 3

[0047] An embodiment of the magnesium-based inorganic adhesive modified with silicon-acrylic emulsion for straw of the present invention and its preparation method, the preparation method of the adhesive comprises the following steps:

[0048] (1) 202 parts by weight of water are placed in the reactor, the temperature is raised to 65°C, and 100 parts by weight of magnesium chloride hexahydrate (wherein the mass fraction of magnesium chloride is 46%) is added and stirred at a constant speed for 5 minutes to form transparent magnesium chloride Solution, stirring speed is 350r / min;

[0049] (2) in above-mentioned magnesium chloride solution, slowly add the magnesium sulfate heptahydrate of 44 parts by weight and stir at a constant speed for 10 minutes;

[0050] (3) Then add 298 parts by weight of light-burned magnesia (wherein the mass fraction of magnesia is 85%) in the reactor, and stir at a constant speed for 15 minutes;

[0051] (4) by dropping funnel, the silicon-acrylic em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com