Preparation of carbon quantum dots from organic wastewater and its coagulation recovery method

A technology of carbon quantum dots and organic wastewater, applied in the field of chemical nanomaterials, can solve the problems of nano-pollution and incomplete removal, and achieve the effects of pollution prevention, simple operation, and simple preparation process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add 2 mL of passivating agent ethylenediamine to 15 mL of coal chemical wastewater, and disperse it ultrasonically for 10 minutes to obtain a uniform liquid;

[0022] 2) Add the above-mentioned liquid into a polyethylene-lined reaction kettle, put it into a microwave oven, use 700W power, and microwave for 2 minutes to obtain a brownish-yellow carbon quantum dot liquid;

[0023] 3) the liquid obtained in step 2) was washed with NaOH / H 2 SO 4 Adjust its pH to neutral.

Embodiment 2

[0025] 1) Add 2 mL of passivating agent ethylenediamine to 15 mL of protein wastewater, and ultrasonically disperse for 5 minutes to obtain a uniform orange liquid;

[0026] 2) Add the above orange liquid into a polyethylene-lined reaction kettle, put it into a microwave oven, use 700W power, and microwave for 4 minutes to obtain a brown-yellow carbon quantum dot liquid;

[0027] 3) the liquid obtained in step 2) was washed with NaOH / H 2 SO 4 Adjust its pH to neutral.

Embodiment 3

[0029] The carbon quantum dots prepared in Example 1 are recovered by titanium coagulation;

[0030] 1) Apply titanium sulfate to configure 2M titanium salt coagulant solution;

[0031] 2) Get 2 milliliters of coagulant and join in the quantum dot concentrate that embodiment one obtains, stir evenly;

[0032] 3) Adjust the pH of the mixed solution in 2) to about 8-9, and stir rapidly for 5 minutes at the same time;

[0033] 4) After stirring slowly for 30 minutes, let it stand for 2 hours;

[0034] 5) filtering to obtain the coagulant solid of adsorbed carbon quantum dots;

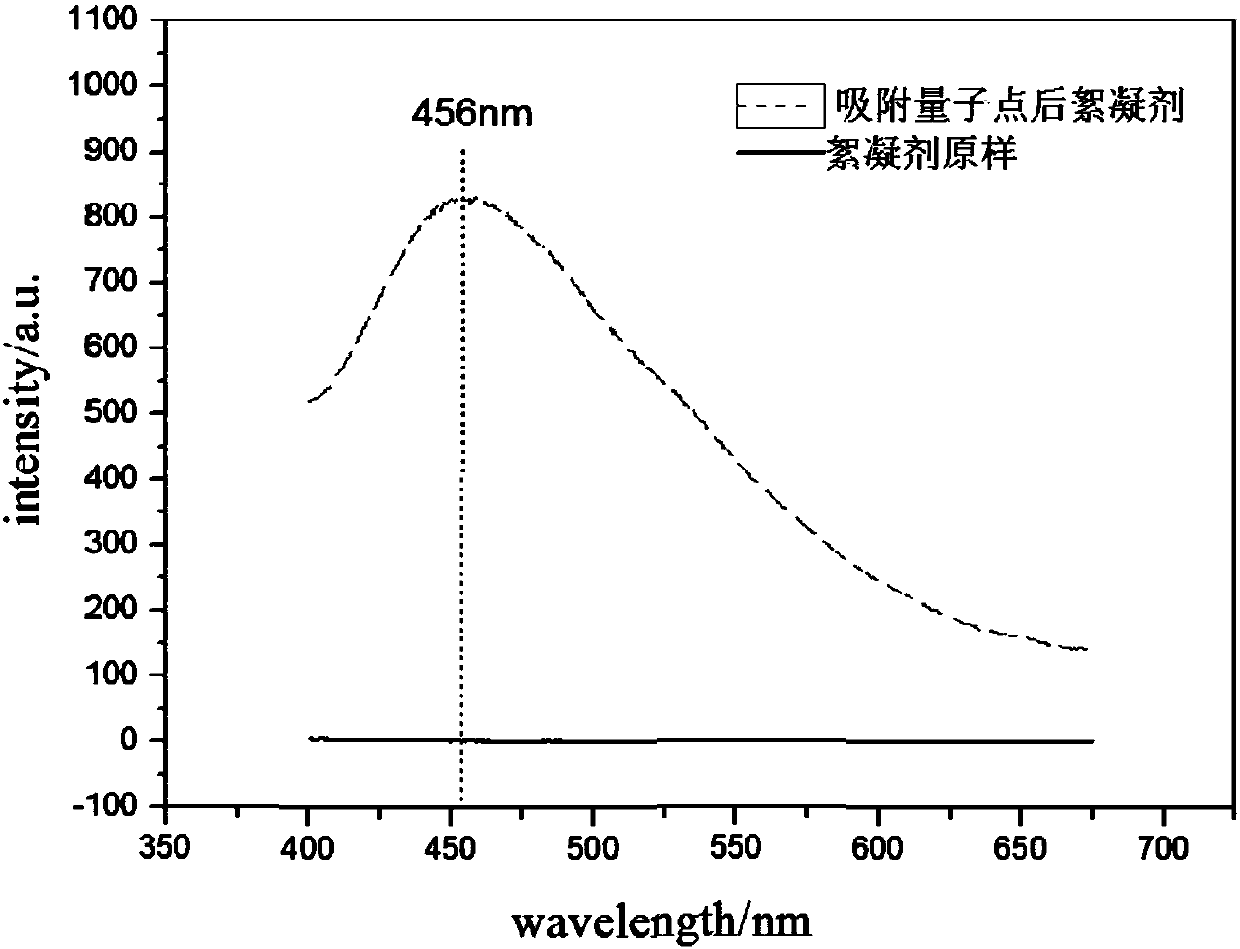

[0035] 5) The UV absorption spectrum of the sample flocculant in step 5) is shown in figure 2 ;

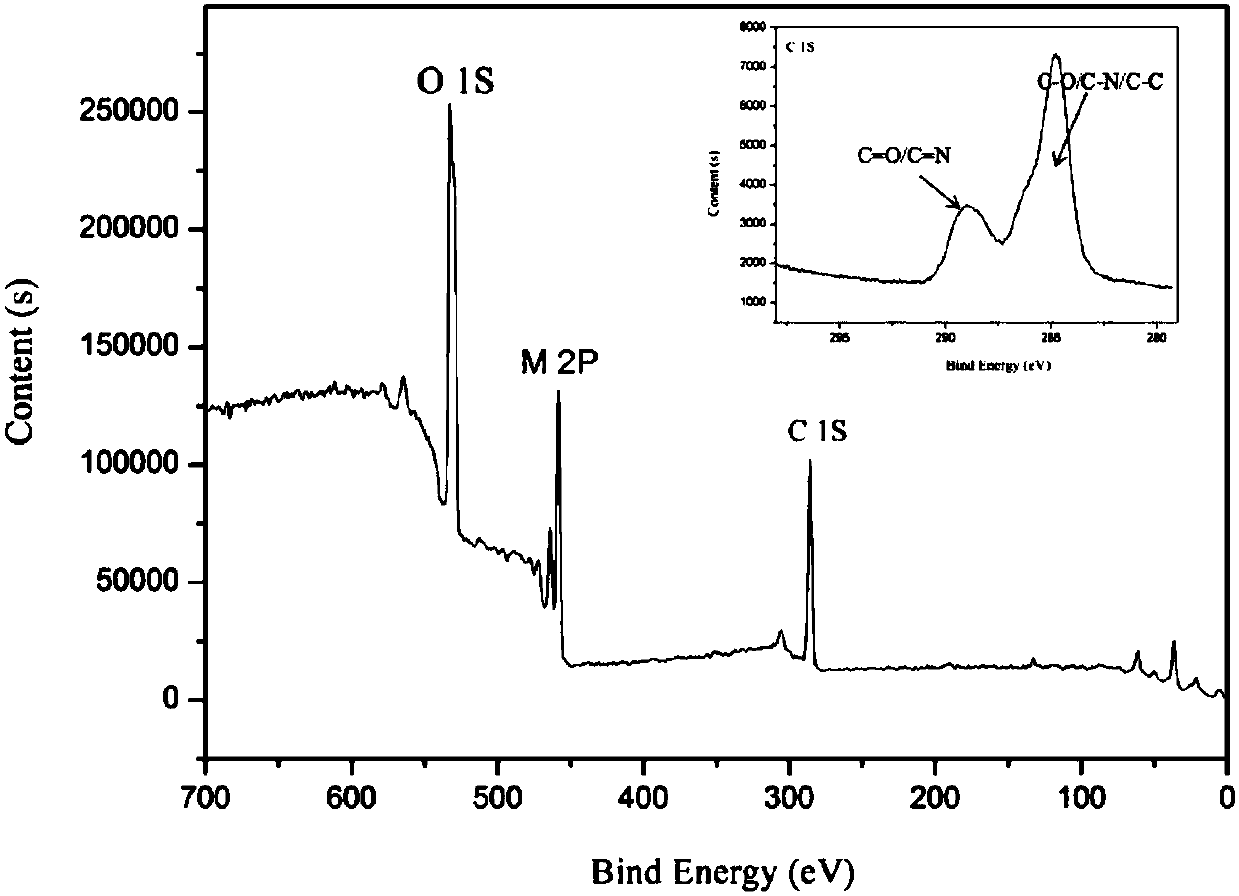

[0036] 6) The coagulant XPS characterization in step 6) is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com