Preparation method of glycosylation enteromorpha oligosaccharide for reducing glucose level and regulating intestinal flora

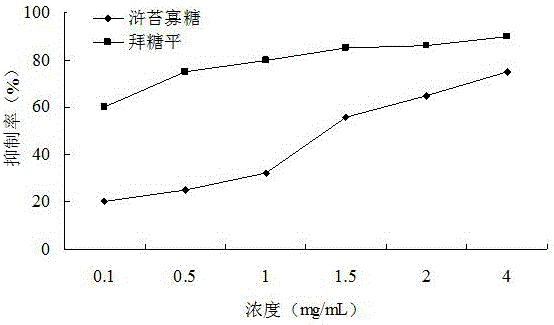

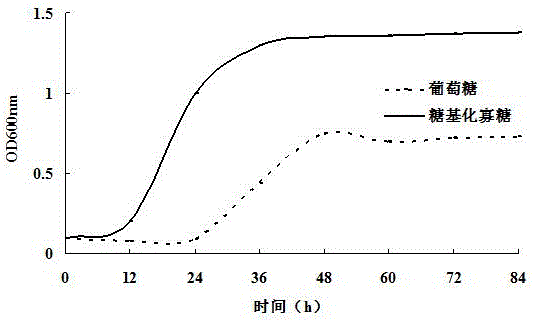

A technology to regulate intestinal flora and Enteromorpha oligosaccharides, which is applied in the direction of medical preparations containing active ingredients, digestive system, pharmaceutical formulas, etc., can solve the problem of glycosylated Enteromorpha oligosaccharides that have not yet been seen to lower blood sugar intestinal probiotics Proliferation function research and other issues, to achieve the effect of increasing commodity value and economic added value, simple operation, and improving the original activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Take the dry, ultrafine pulverized Enteromorpha powder passed through a 80-mesh sieve, add an ethanol solution with a mass concentration of 60% at a weight-to-volume ratio (g / mL) of 1:20, and extract with 200W ultrasound at 60°C for 1 hour. After the extraction is completed, filter, repeat the above steps for 2 extractions on the filter residue, combine the extracts, mix the obtained filtrates, concentrate under reduced pressure to 3% of the original volume, freeze-dry in a vacuum, then pulverize, and pass through a 50-mesh sieve;

[0018] (2) Add distilled water to the powder obtained in step (1), wherein the powder mass to distilled water volume ratio is (g / mL) 1:10, stir and redissolve, and use trifluorotrichloroethane method to remove protein 3 times;

[0019] (3) Pass the solution obtained in step (2) through the column filled with HPD-826 macroporous adsorption resin, and the eluent is further passed through the non-polar adsorbent activated carbon. mL) 1:30 t...

Embodiment 2

[0026] (1) Take the dry, ultrafine pulverized, 100-mesh sieve powder of Enteromorpha enteromorpha, add 80% ethanol solution at a weight-to-volume ratio (g / mL) of 1:30, and extract with 400W ultrasound at 90°C for 1.5 hours. After the extraction is completed, filter, repeat the above steps for 3 extractions on the filter residue, combine the extracts, mix the obtained filtrates, concentrate under reduced pressure to 8% of the original volume, freeze-dry in a vacuum, then pulverize, and pass through an 80-mesh sieve;

[0027] (2) Add distilled water to the powder obtained in step (1), wherein the powder mass to distilled water volume ratio is (g / mL) 1:20, stir and redissolve, and use the Sevag method to remove protein 5 times;

[0028] (3) Pass the solution obtained in step (2) through HPD-826 macroporous adsorption resin-packed column, and the eluent is further passed through the non-polar adsorbent activated carbon, and the amount of activated carbon used and the eluent are in ...

Embodiment 3

[0035] (1) Take the powder of Enteromorpha enteromorpha that has been dried, ultrafinely pulverized and passed through a 90-mesh sieve, add ethanol solution with a mass concentration of 75% at a weight-to-volume ratio (g / mL) of 1:26, and extract with 300W ultrasound at 75°C for 1.3 hours. After the extraction is completed, filter, repeat the above steps for 3 extractions on the filter residue, combine the extracts, mix the obtained filtrates, concentrate under reduced pressure to 5% of the original volume, freeze-dry in a vacuum, then pulverize, and pass through a 70-mesh sieve;

[0036] (2) Add distilled water to the powder obtained in step (1), wherein the powder mass to distilled water volume ratio is (g / mL) 1:16, stir and redissolve, and use trichloroacetic acid method to remove protein 4 times;

[0037] (3) Pass the solution obtained in step (2) through the column filled with HPD-826 macroporous adsorption resin, and the eluent is further passed through the non-polar adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com