Comprehensive recovery process of low-grade matte slag metal resources

A low-grade, matte technology, applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of no harmless resource recycling process, high cost of iron removal, waste of resources, etc. , to achieve high environmental and economic benefits, reduce the cost of iron removal, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

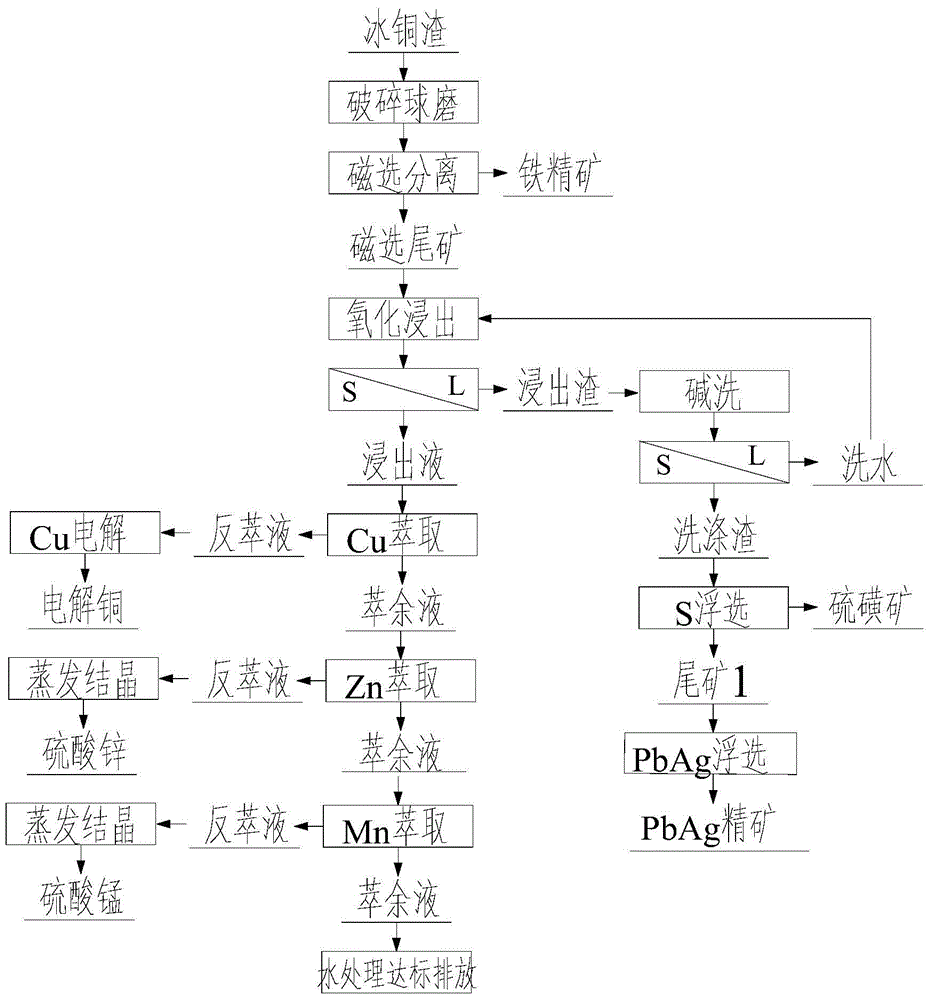

[0029] A comprehensive recovery process for low-grade matte slag metal resources, comprising the following processing steps:

[0030] 1) The composition of matte slag produced by a factory: Cu4.1%, Pb5.44%, Fe38.37%, Zn1.41%, Ag0.05%, CaO3.3%, S8.06%; this sample is broken After ball milling until 95% of the sample particle size is less than 0.074mm, take 500g of the sample, mix it according to the proportion of solid content of 25%, and then use permanent magnet semi-countercurrent magnetic separator for magnetic separation. The magnetic field strength is 800 gauss, and the yield of iron concentrate is 13.3%, the obtained iron concentrate grade reaches 70.04%;

[0031] 2) Take 100g of magnetic separation tailings and add it to a beaker filled with 500ml of sulfuric acid solution with a concentration of 2mol / L. At the same time, add 1.1 times the theoretical amount of pyrolusite. Place the beaker in a water bath that has been heated to 95°C and stir for 2 hours. After filteri...

Embodiment 2

[0039] A comprehensive recovery process for low-grade matte slag metal resources, comprising the following processing steps:

[0040] 1) The composition of matte slag produced by a factory: Cu2.57%, Pb5.18%, Zn4.68%, Ag0.039%, Fe50.74%, S20.74%; this sample is broken and ball milled to 100% sample After the particle size is less than 0.074mm, take a 300g sample, mix the slurry according to the proportion of solid content of 30%, and then use a permanent magnet semi-countercurrent magnetic separator for magnetic separation. The magnetic field strength is 800 gauss, and the iron concentrate yield is 13.6%. The obtained iron Concentrate grade reaches 67.7%;

[0041] 2) Take 100g of magnetic separation tailings and add it to a beaker filled with 500ml of sulfuric acid solution with a concentration of 2mol / L. At the same time, add a theoretical amount of pyrolusite. Put the beaker in a water bath that has been heated to 90°C, stir for 3 hours, and then filter . The leaching rates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com