Method for carrying out two-stage countercurrent leaching on chromium-containing vanadium slag and extracting vanadium and chromium in separating manner

A countercurrent leaching and vanadium slag technology, applied in the direction of improving process efficiency, etc., can solve problems such as waste of resources, equipment corrosion, and ineffective use of iron resources, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

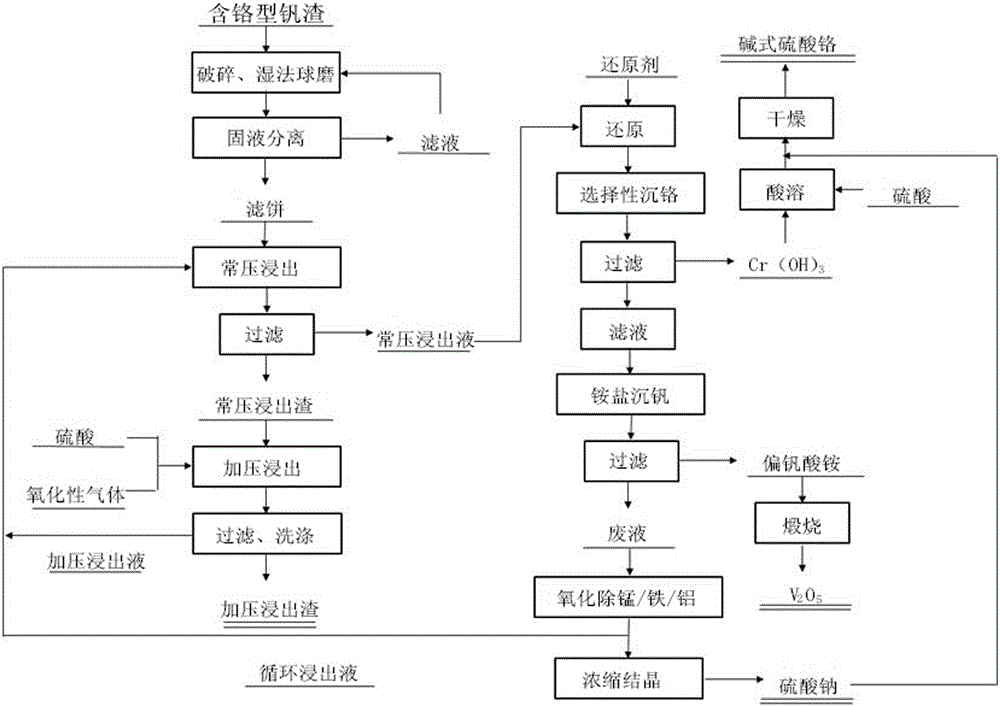

[0031] The two-stage countercurrent leaching of chromium-containing vanadium slag and the method for separating and extracting vanadium and chromium in this embodiment are as follows figure 1 As shown, follow the steps below:

[0032] (1) Pretreatment: crush the chromium-containing vanadium slag, separate the solid and liquid after wet ball milling, to obtain the chromium-containing vanadium slag filter cake, the particle size of the chromium-containing vanadium slag in the filter cake is less than 200 mesh;

[0033] (2) Atmospheric leaching: the chromium-containing vanadium slag filter cake is leached at atmospheric pressure. The reaction temperature of the atmospheric leaching is 90℃, the reaction time is 10h, and the pH of the atmospheric leaching solution at the end of the reaction is controlled at 1.2. After filtration, atmospheric leaching is obtained. Slag and atmospheric leachate;

[0034] (3) Pressure leaching and selective chromium precipitation: the thickened atmospheric ...

Embodiment 2

[0040] The two-stage countercurrent leaching of chromium-containing vanadium slag and the method for separating and extracting vanadium and chromium in this embodiment are as follows figure 1 As shown, follow the steps below:

[0041] (1) Pretreatment: crush the chromium-containing vanadium slag, separate the solid and liquid after wet ball milling, to obtain the chromium-containing vanadium slag filter cake, the particle size of the chromium-containing vanadium slag in the filter cake is less than 200 mesh;

[0042] (2) Atmospheric leaching: the chromium-containing vanadium slag filter cake is leached at atmospheric pressure. The reaction temperature of atmospheric leaching is 95℃, the reaction time is 8h, and the pH of the atmospheric leaching solution at the end of the reaction is controlled at 1.5. After filtration, atmospheric leaching is obtained. Slag and atmospheric leachate;

[0043] (3) Pressure leaching and selective chromium precipitation: the thickened atmospheric leach...

Embodiment 3

[0049] The method for the two-stage countercurrent leaching and separation and extraction of chromium-containing vanadium slag in this embodiment is as follows figure 1 As shown, follow the steps below:

[0050] (1) Pretreatment: crush the chromium-containing vanadium slag, separate the solid and liquid after wet ball milling, to obtain the chromium-containing vanadium slag filter cake, the particle size of the chromium-containing vanadium slag in the filter cake is less than 200 mesh;

[0051] (2) Atmospheric pressure leaching: the chromium-containing vanadium slag filter cake is leached at atmospheric pressure. The reaction temperature of atmospheric leaching is 25℃, the reaction time is 2h, and the pH of the atmospheric leaching solution at the end of the reaction is controlled at 1.8. After filtration, atmospheric pressure is obtained. Leaching residue and atmospheric leachate;

[0052] (3) Pressure leaching and selective chromium precipitation: the thickened atmospheric leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com