A method of simultaneously measuring contents of Al, Cu, Mn, P and Si in ferrotitanium by utilizing an inductively coupled plasma emission spectrometer

A plasma and inductive coupling technology, applied in the field of Mn, simultaneous detection of Al, Cu, P and Si element content in ferrotitanium, can solve the problems of lengthy steps, secondary pollution of the environment, complex and cumbersome operation, etc., to ensure accurate detection Accuracy and accuracy, improve work efficiency, improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] 1. Equipment and working conditions

[0029] Instrument used: ICAP6300 full-spectrum direct-reading inductively coupled plasma emission spectrometer (Thermo Fisher Corporation, USA). Instrument working conditions: RF power 1150w; pump speed 50r / min; auxiliary gas flow 0.5L / min; atomizer flow 0.65L / min; observation height 15cm; integration time 30s.

[0030] 2. Main reagents and standard solutions

[0031] The reagents used in the present invention are all high-grade pure, and the experimental water is the first-grade water that meets the requirements in GB / T6682.

[0032] Hydrochloric acid (ρ=1.42g / ml) superior grade pure;

[0033] Nitric acid (ρ=1.19g / ml) superior grade pure;

[0034] Aqua regia (hydrochloric acid: nitric acid=3:1);

[0035] Hydrofluoric acid (ρ=1.15g / ml) superior grade;

[0036] High-purity iron, the mass fraction is 99.98%;

[0037] High-purity titanium with a mass fraction of 99.98%;

[0038] National standard aluminum solution, concentration...

PUM

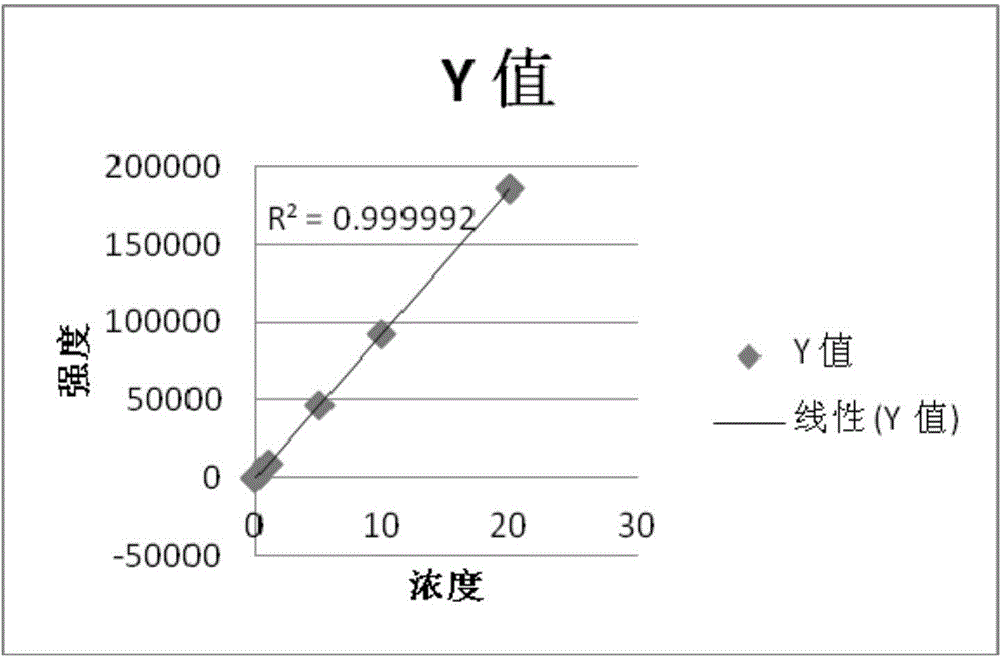

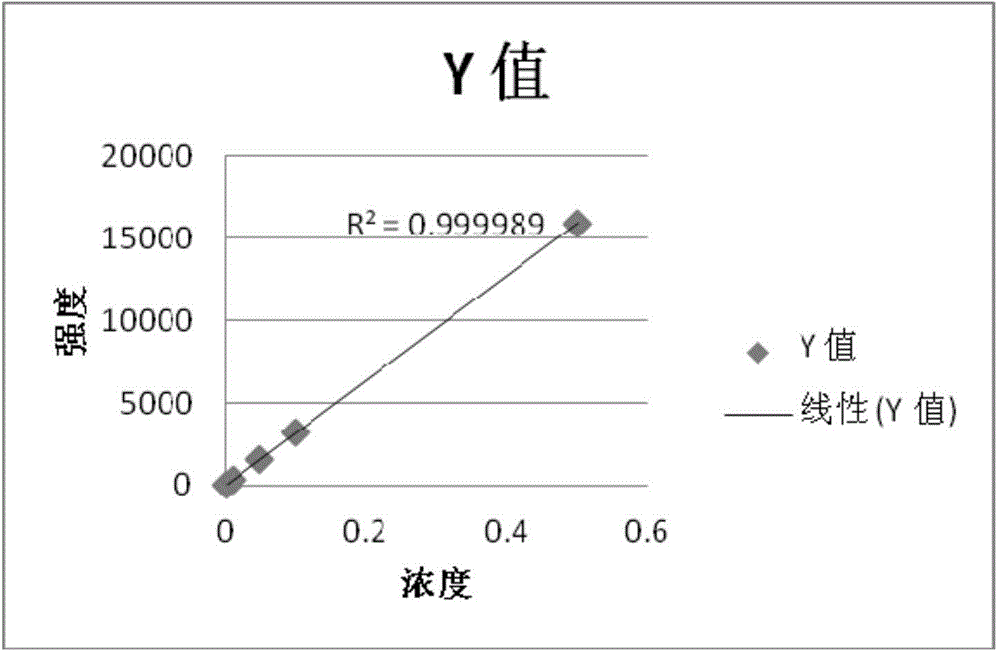

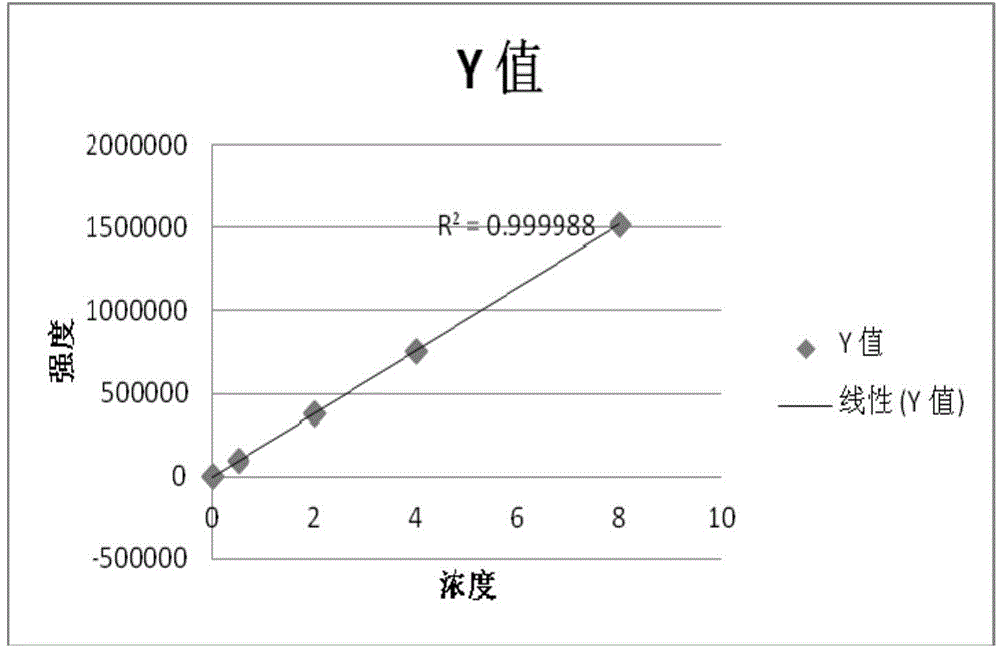

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com