Dental pit and fissure sealant and preparation method thereof

A pit and fissure sealing and dental technology, which is applied in the field of dental pit and fissure sealant and its preparation, can solve the problems of difficulty in uniform dispersion of ultrafine inorganic fillers, increased shrinkage rate of pit and fissure sealant, low bonding strength, etc. Accelerated polymerization and curing process, less heat release, high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific preparation method of the dental pit and fissure sealant provided by embodiment 1 is as follows:

[0038] (1) Add the components of 100g base resin (the content of each component in the base resin is as described in Table 1) into a planetary mixer and keep the temperature at 25°C, and start the planetary mixer for 30 minutes To mix the resin phase; add 150g concentration of 20wt% nano-zirconia ethanol solution to it and continue mixing for 1 hour, wherein the particle size of zirconium oxide is 5-10nm; The ethanol solvent was removed by drying at -0.1MPa for 1 hour to obtain a mixture of nano zirconia and base resin with a nano zirconia content of 23%.

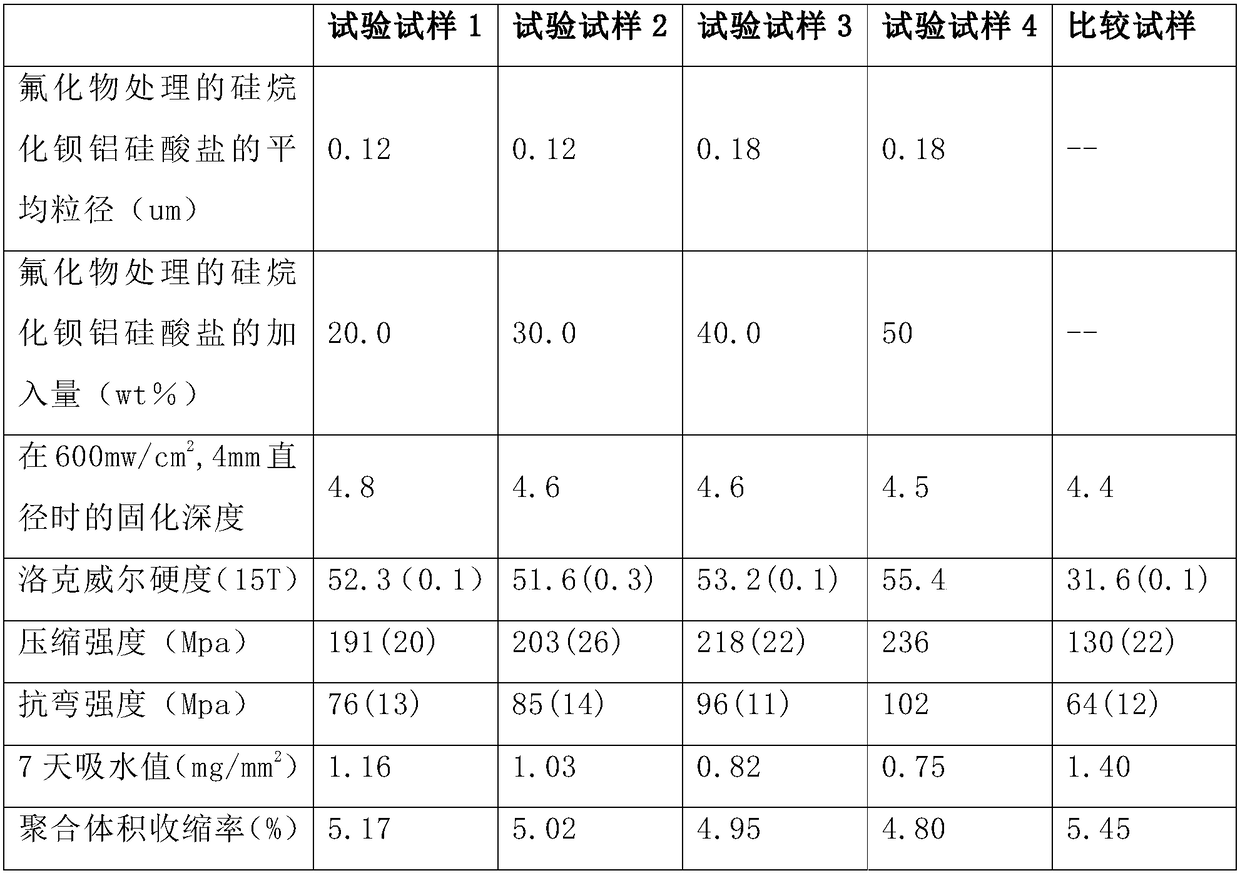

[0039] (2) Prepare test sample 1 (that is, the mass ratio of the filler to the mixture of nano-zirconia and base resin is 20:80) with 20wt% filler filled into the mixture of nano-zirconia and base resin, with 30wt% filler Filling nano zirconia composite resin to prepare test sample 2 (i.e. the mass ratio o...

Embodiment 2

[0046] The specific preparation method of the dental pit and fissure sealant provided by embodiment 2 is as follows:

[0047] (1) Add the components of 100g base resin (the composition of the base resin in Example 2 of the present invention is as described in Table 3) into a planetary mixer and keep the temperature at 25°C, and start the planetary mixer 30 minutes to mix the resin phase; add 150g of 20% nanometer zirconia ethanol solution to it and continue mixing for 1 hour, wherein the particle size of zirconia is 5-10nm, and the mixed solution is evaporated in a light-proof environment Drying at -0.1 MPa for 1 hour to remove the ethanol solvent to obtain a nano-zirconia composite resin with a nano-zirconia content of 23%.

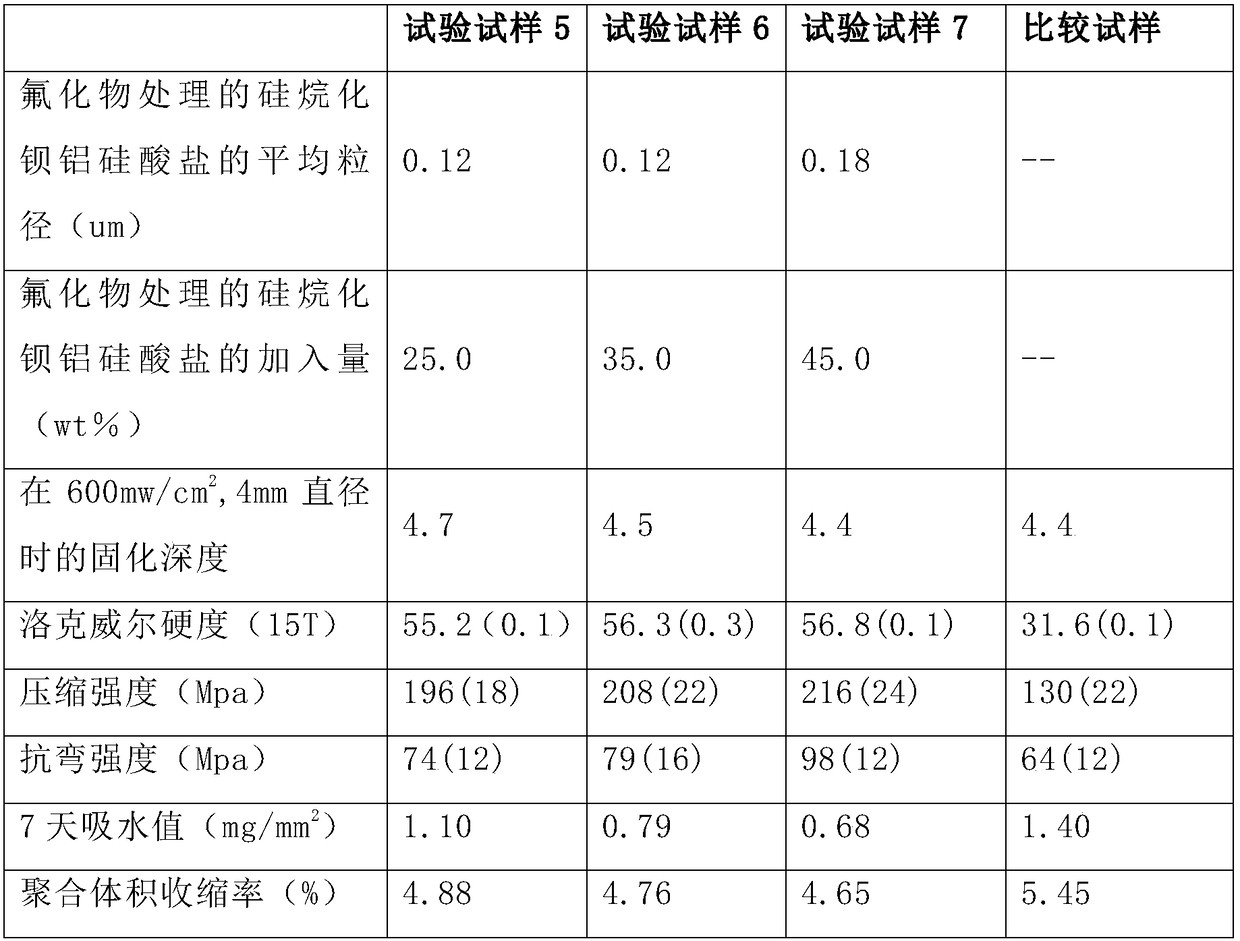

[0048] (2) Prepare test sample 5 (that is, the mass ratio of the filler to the mixture of nano-zirconia and base resin is 25:75) filled with 25wt% filler into the mixture of nano-zirconia and base resin, with 35wt% filler Filling nano zirconia composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com