Graphene-doping-modified protective coating and preparing method and application thereof

A protective coating, graphene technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings and other directions, can solve the problems of harsh conditions, many chemical reagents, increase production costs, etc., to achieve low cost and improve protective performance , controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method steps of the protective coating modified by graphene doping are as follows:

[0028] 1) After the metal substrate is mechanically polished as required, put it in a degreasing solution at 30-60°C for 1-10 minutes, then ultrasonically at 30-60°C for 5-15 minutes, and finally wash it with tap water and deionized water in sequence, and quickly Blow dry with hot air and place in a drying box for 5-24 hours for later use;

[0029] 2) Preparation of silica precursor solution: add 50-100mL absolute ethanol, 50-100mL water, 1-10mL SiO 2 For the precursor, adjust the pH to 2.0-6.0, stir at room temperature for 2-48 hours, and set aside;

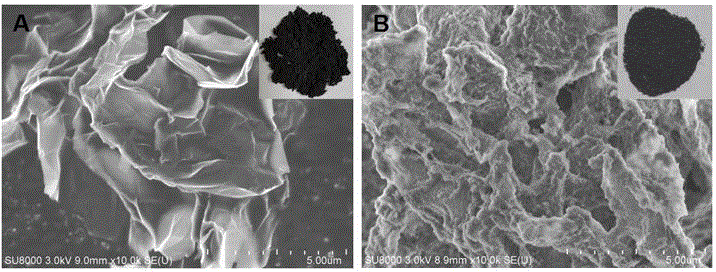

[0030] 3) Add the prepared precursor solution into the three-electrode electrolytic cell, then add 1-100mg of graphene, and stir and mix evenly with ultrasonic power of 100-200W for 1-10min. Ag / AgCl is used as the reference electrode, platinum sheet It is working electrode; Described three-electrode electrolyzer can be m...

Embodiment 1

[0042] The AA2024 aluminum alloy substrate was subjected to No. 80, No. 120, and No. 400 electrostatic sanding in sequence, and mechanically polished with No. 14 metallographic sandpaper, then put it in a degreasing solution at 60°C for 10 minutes, then ultrasonicated at 30°C for 10 minutes, and finally used tap water to remove the oil. After cleaning with deionized water, dry it quickly with hot air, and place it in a drying box for 5 hours to be used; the components of the degreasing liquid are sodium carbonate 8g / L, sodium silicate 5g / L, sodium polyphosphate 8g / L, ten Sodium dialkylsulfonate 1g / L, alkylphenol polyoxyethylene ether 5mL / L;

[0043] Precursor solution preparation: add 50mL absolute ethanol, 50mL deionized water, 5mL tetraethyl silicate, 2M nitric acid solution to adjust the pH to ~5.0, stir at room temperature for 24h, and set aside;

[0044] Add the prepared precursor solution into the special three-electrode tank, then add about 0.0020g of graphene, stir and...

Embodiment 2

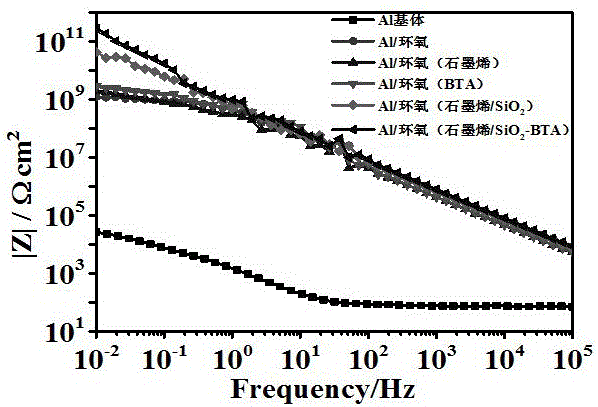

[0053] The specific implementation steps are similar to those in Example 1, except that the metal substrate is replaced by low-carbon steel. The difference is that the low-carbon steel substrate does not need to be sanded, and the degreasing step is directly performed. In addition, the corrosion inhibitor was changed from BTA to thiourea suitable for steel. The protective performance of the protective film system was tested by electrochemical impedance spectroscopy (EIS), and the test solution used was 3.5wt% NaCl aqueous solution. The results show that the direct doping of graphene and thiourea in the coating has no effect on the protective performance of the coating, and the doping of electrodeposited SiO 2 The protective performance of the modified graphene epoxy coating has been significantly improved, while the use of graphene / SiO 2 Doping after adsorption of thiourea can greatly improve the protective performance of the coating. Table 2 lists the low-frequency impedanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com