Epitaxial growth method for increasing p-type doping concentration of nitride light-emitting diodes

A technology for light-emitting diodes and epitaxial growth, which is applied in the fields of nanotechnology, electrical components, and nanotechnology for materials and surface science. It can solve problems such as difficulty in achieving hole concentration, difficulty in obtaining N materials, and difficulty in obtaining high hole concentration , to reduce self-compensation effect, improve crystal quality and reduce self-compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

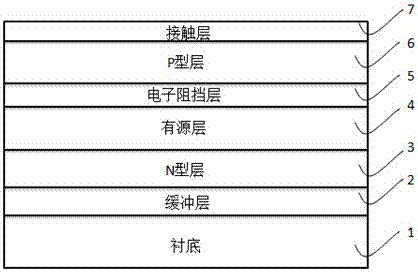

[0031] A method for epitaxial growth of a nitride light-emitting diode that can increase the P-type doping concentration, such as figure 1 As shown: a buffer layer 2 , an N-type layer 3 , a light-emitting active layer 4 , an electron blocking layer 5 , a P-type layer 6 and a contact layer 7 are grown sequentially on a substrate 1 .

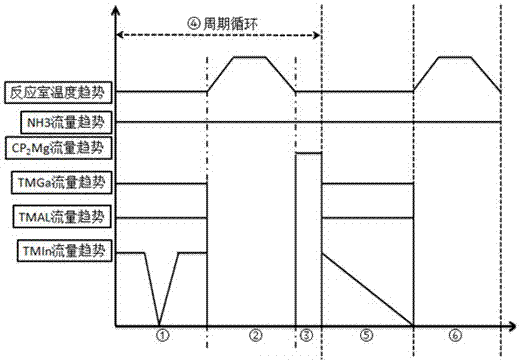

[0032] Wherein the P-type layer 6 is Al X Ga 1-X N floor, the whole production except in N 2 and ammonia (NH 3 ) atmosphere, and if figure 2 As shown, the specific growth method of this layer is as follows:

[0033] 1. Introduce ammonia gas (NH 3 ), trimethylgallium (TMGa), trimethylaluminum (TMAl), grow a layer of Al X Ga 1-XN thin layer, the growth thickness is 5-25nm, and the growth temperature is 900°C-1100°C.

[0034] During the growth process of this layer, a small amount of trimethylindium (TMIn) is also introduced: the flow rate of trimethylindium (TMIn) in this stage is the same uniform flow rate first and last, and in the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com