Light emitting diode with adjustable light colors and preparation method therefor

A light-emitting diode and light color technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of low radiation recombination efficiency of LEDs, and achieve the effect of improving radiation recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing light-color-tunable light-emitting diodes, comprising the following steps:

[0035] (1) Prepare the substrate;

[0036] (2) growing an epitaxial layer on the substrate, the epitaxial layer comprising a first multiple quantum well layer;

[0037] (3) Etching a number of micro-nano holes on the first multi-quantum well layer, the micro-nano holes running through the first multi-quantum well layer;

[0038] (4) epitaxially growing a second multi-quantum well structure in the micro-nano hole until it is flush with the upper surface of the first quantum well layer.

[0039] For the selection of the substrate, it may be a substrate commonly used in the preparation of LED technology, preferably a sapphire substrate, a silicon substrate, a gallium nitride substrate or a gallium oxide substrate.

[0040] For the specific process of step (3) photolithographic etching, it can be: on the first multi-quantum well layer, ep...

Embodiment 1

[0055] Embodiment 1 of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment provides a method for manufacturing a single-chip white light-emitting diode with tunable light color and no phosphor powder. Include the following steps:

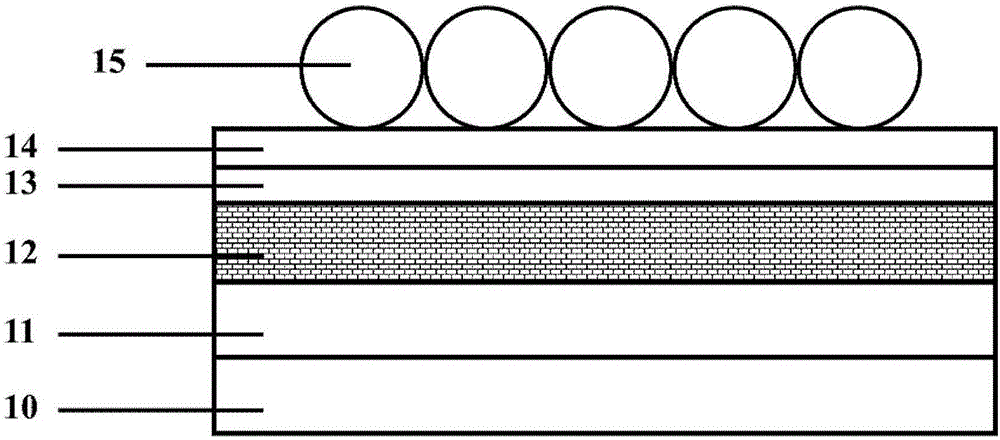

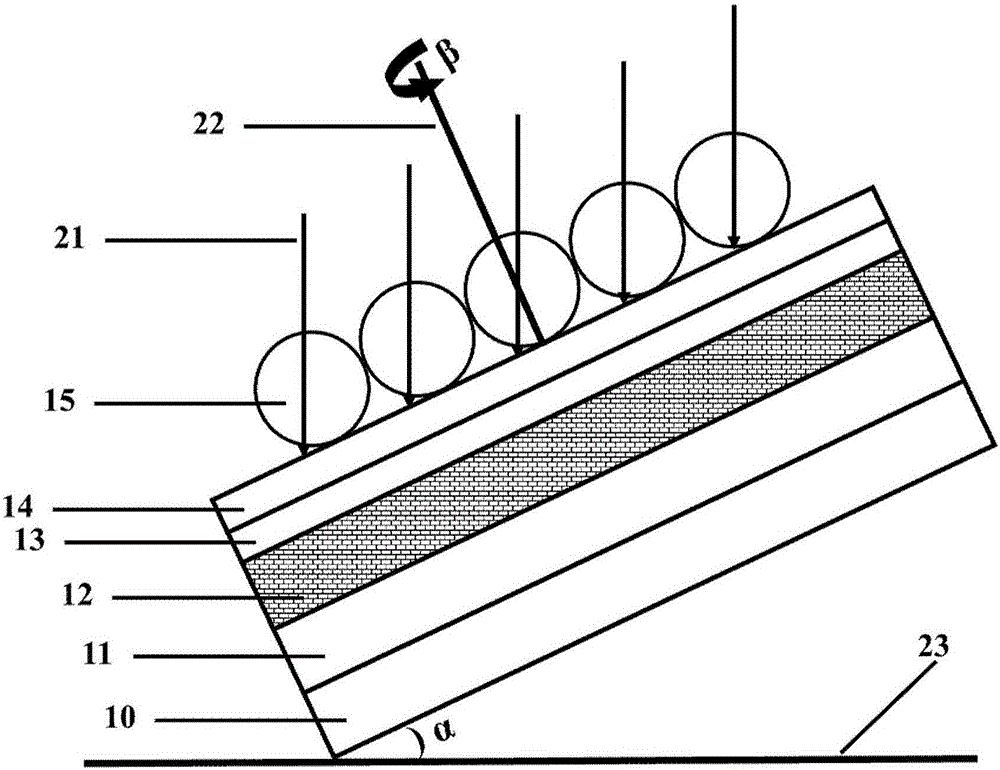

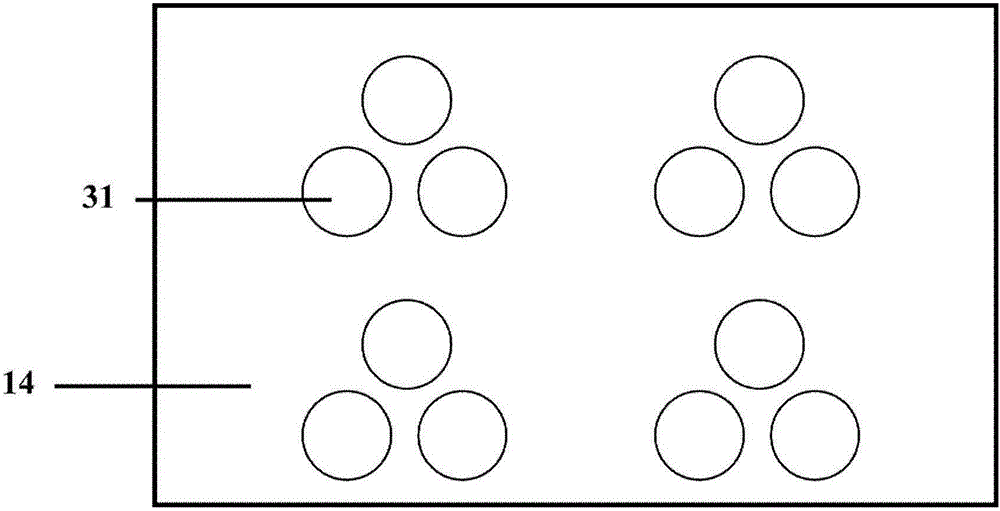

[0056] Step 1: On the sapphire substrate 10, epitaxially grow a buffer layer, an unintentionally doped gallium nitride layer, an n-type gallium nitride layer 11, and a blue multi-quantum well layer 12 sequentially by metal-organic chemical vapor deposition, and then use plasma A layer of 100-1000nm silicon dioxide insulating dielectric thin film passivation layer 13 is grown by volume-enhanced chemical vapor deposition (PECVD), and then a positive photoresist 14 is spin-coated on the 13, and the positive photoresist is formed by spin-coating or pulling method. Self-assembled single-layer polystyrene microspheres 15 on the resist 14, with a diameter of 100-10000 nm, such as figure 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com