Method for preparing silicon dioxide aerogel composite material

A technology of silica and composite materials, applied in the chemical industry, which can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

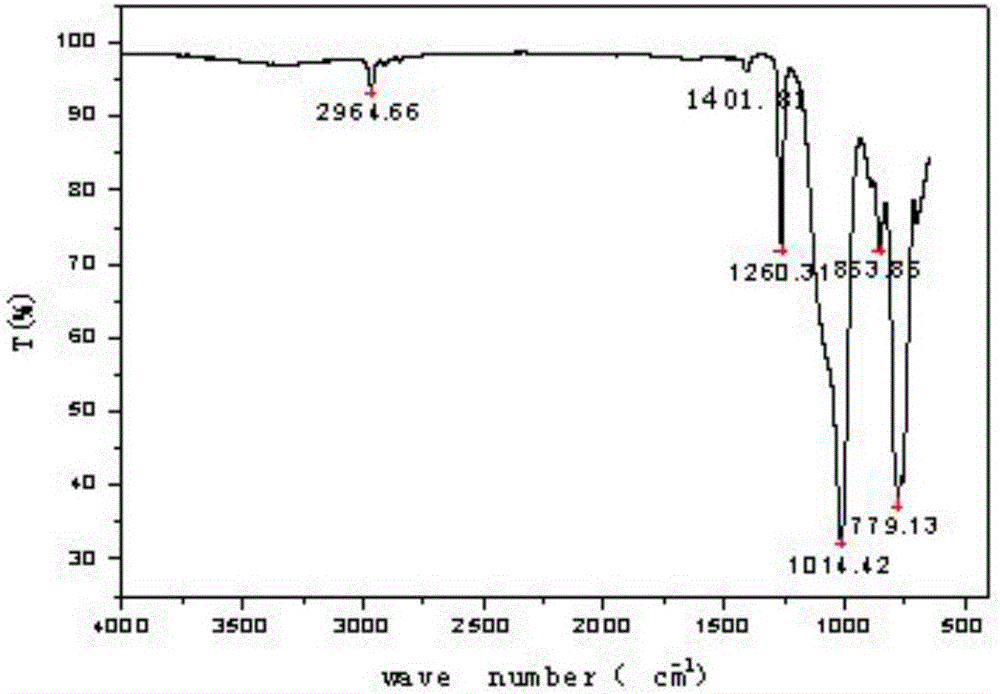

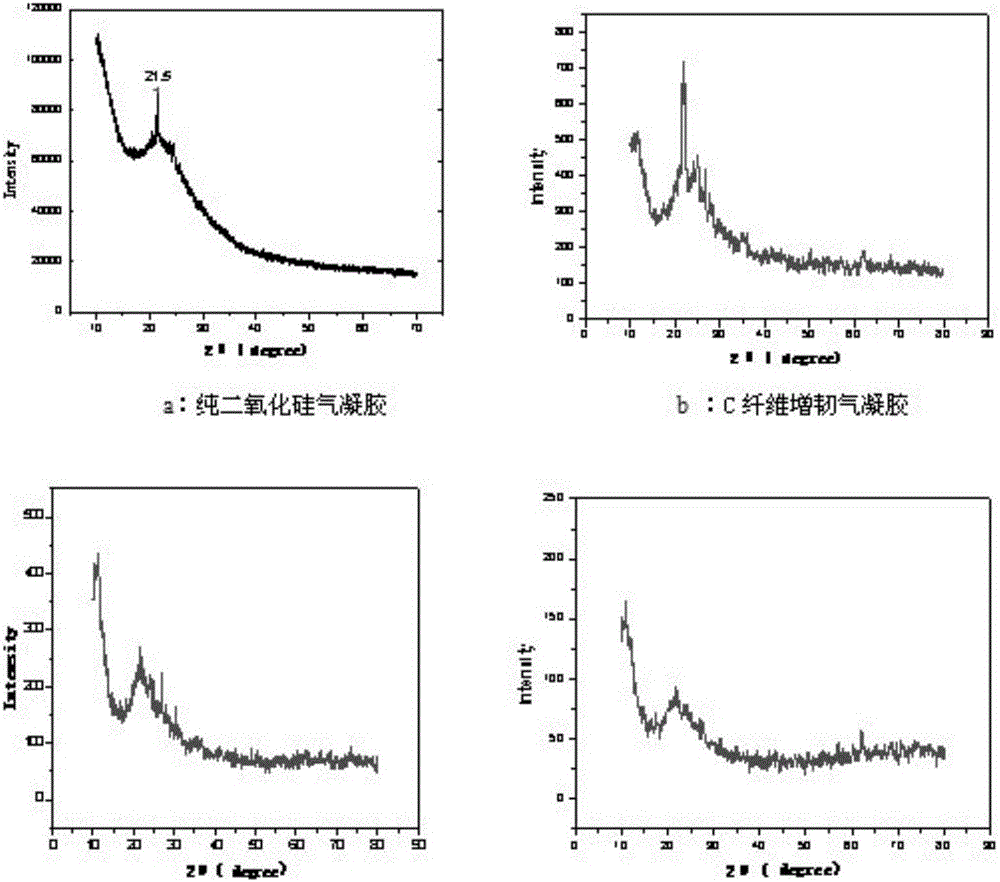

[0019] The preparation of embodiment 1 pure silica airgel

[0020] First, weigh a certain amount of surfactant (hexadecyltrimethylammonium bromide) and add it to the beaker, then add methanol and acetic acid solution with a volume ratio of 1:3, stir to dissolve the surfactant, and then add volume MTMS (methyltrimethoxysilane) and DMDMS (dimethyldimethoxysilane) with a ratio of 3:2 and a certain amount of DMF (N,N-dimethylformamide), placed in a constant temperature magnetic stirrer In the process, stir for 1 hour at 30°C to make it fully hydrolyzed, then add lye to adjust the pH value, stir to make the lye and the solution fully mixed, and place it in a constant temperature water bath at 40°C until the solution forms a gel. After aging for 6 hours, alcohol solution and alkane were added to replace them for 6 hours, and finally dried under normal pressure to prepare elastic airgel.

Embodiment 2

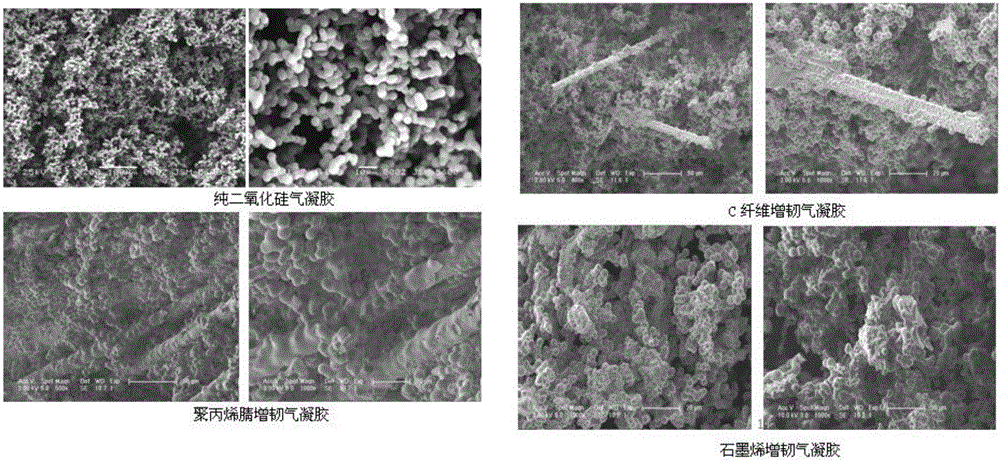

[0021] Embodiment 2 Preparation of carbon fiber toughened airgel

[0022] In the process of preparing airgel, add about 2mm of carbon fiber, magnetic stirring, add dispersant MC (methyl cellulose), CMC (sodium hydroxymethyl cellulose) to disperse the fiber, form a gel, and further age and solvent replacement, and finally dried. The effect of different dispersant additions on the fiber dispersion effect is shown in Table 2-3.

[0023] Table 1 Effect of different dispersant additions on fiber dispersion effect

[0024]

[0025] It can be seen from Table 1 that CMC has the best dispersion effect, and CMC is selected as the dispersant.

Embodiment 3

[0026] The preparation of embodiment 3 graphene toughened airgel

[0027] During the preparation process of the airgel, a certain amount of graphene is added, stirred and mixed, and the graphene is evenly dispersed in it, then a gel is formed, and finally dried. The material is characterized by excellent elasticity, like a sponge, and has very good bending and compression properties. The airgel after adding graphene is supported by graphene as a skeleton, which enhances its toughness and improves its repeated use performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com